Cov khoom

-

Hlau Granulating Tshuab rau Kub Silver Copper Alloy 20kg 30kg 50kg 100kg 150kg

1. Nrog kev tswj qhov kub thiab txias, qhov tseeb txog li ± 1 ° C.

2. Ultra-tib neeg tsim, kev ua haujlwm yooj yim dua li lwm tus.

3. Siv cov maub los Mitsubishi tuaj.

4. Silver Granulator nrog tempterature tswj (Gold Silver Grains Casting Machine, Silver Granulating Machine).

5. Lub tshuab no siv IGBT cov tshuab cua sov siab tshaj plaws, cov nyhuv casting yog qhov zoo heev, lub kaw lus ruaj khov thiab nyab xeeb, molten kub muaj peev xwm xaiv tau, thiab cov hlau granulated yog xaiv tau.

6. Lub granulation ceev ceev thiab tsis muaj suab nrov.Kev soj ntsuam zoo tshaj plaws thiab kev tiv thaiv kev ua haujlwm ua rau tag nrho lub tshuab muaj kev nyab xeeb thiab ruaj khov.

7. Lub tshuab muaj kev sib cais tsim thiab lub cev muaj ntau qhov chaw dawb.

-

Compact me Me Metal Granulator Granulating Equipment for Gold Silver

Me me hlau txhaj tshuaj.Nrog kev tswj kub, qhov tseeb txog li ± 1 ° C.

Ultra-tib neeg tsim, kev ua haujlwm yooj yim dua li lwm tus.

Siv cov maub los Mitsubishi imported.

Thov rau VC series lub tshuab nqus tsev siab casting tshuab, nruab nrog 304 SS dej tank.Granulator nrog kub tswj (Gold Silver Grains Casting Tshuab, Nyiaj Granulating Tshuab).

Lub tshuab no siv lub teb chaws Yelemees IGBT advanced cua sov tshuab, cov nyhuv casting yog qhov zoo heev, lub kaw lus ruaj khov thiab muaj kev nyab xeeb, lub peev xwm kub kub yog xaiv tau, thiab cov hlau granulated yog xaiv tau.Lub granulation ceev yog ceev thiab tsis muaj suab nrov.Kev soj ntsuam zoo tshaj plaws thiab kev tiv thaiv kev ua haujlwm ua rau tag nrho lub tshuab muaj kev nyab xeeb thiab ruaj khov.Lub tshuab muaj kev sib cais tsim thiab lub cev muaj ntau qhov chaw dawb.Siv tsis muaj cua compressor, casting los ntawm manually mechanical qhib stopper.

Qhov no AG Series granulating system yog tsim rau me me peev xwm ntawm 1kg txog 6kg muaj peev xwm (kub), nws yog qhov zoo rau cov neeg siv khoom uas muaj qhov chaw me me.

-

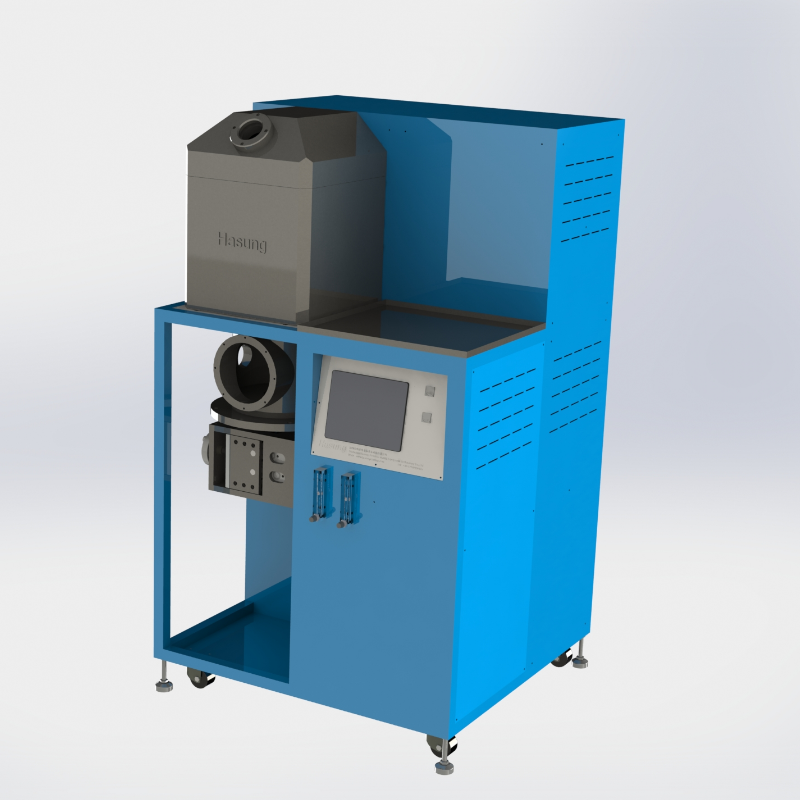

Hlau hmoov Dej Atomizer Rau Precious Hlau Powder Kub Silver Copper

Khoom Specifications

Induction cua sov nyob rau hauv kev tiv thaiv ntawm inert roj, siv graphite crucible, melting kub mus txog 1600 degrees.HT kub hom tuaj yeem siv tau, siv cov ceramic crucible (graphite susceptor), qhov kub ntawm qhov kub tuaj yeem ncav cuag 2000 degrees.Lub tshuab hluav taws xob kub tuaj yeem muab ntxiv, qhov twg cov roj tau rhaub rau 500 degrees rau kev tsim cov hmoov hlau zoo dua.Cov cuab yeej tsim cov hmoov hlau kheej kheej nrog cov dej ntws zoo thiab qhov loj me ntawm 10 thiab 200 microns, ntau dua mus txog # 400, 500 #.Nws tuaj yeem siv rau hauv kev tsim khoom xws li laser xaiv sintering thiab hmoov metallurgy.Qhov zoo ntawm Hasung AU series khoom:

- Compact qauv thiab ua haujlwm yooj yim

- Yooj yim thiab ua tau zoo ntawm cov khoom me me ntawm cov hmoov hlau

- Yooj yim thiab ceev alloy hloov thiab hloov nozzle

- Cov hmoov nplej siab heev thiab milling poob tus nqi qis li 1/1000

- Cov txheej txheem tsim khoom ruaj khovCov yam ntxwv tseem ceeb ntawm Hasung AU Series Devices:

- Graphite crucible tuaj yeem ua kom sov txog 2000 degrees hauv qhov chaw tiv thaiv roj

- Microprocessor tswj induction lub cev muaj zog (400 volts, 3 theem zog)

- Cov kua hlau sib xyaw ua haujlwm zoo heev, uas tuaj yeem fuse thiab smelt sib txawv hlau ua ntej roj atomization

- Nyob rau hauv ib puag ncig ntawm kev tiv thaiv roj, lub tshuab pub mis tuaj yeem muab ntxiv los hloov cov alloy muaj pes tsawg leeg

- Tswj qhov kub thiab txias siv N-hom thiab S-hom thermocouples

- Crucible muaj peev xwm 1500cm3, 3000cm3 thiab 12000cm3 yeem

- Siv argon lossis nitrogen mus txog 30 cua

- Lub tshuab cua sov tuaj yeem muab ntxiv los ua kom sov cov roj rau 500 degrees rau kev tsim cov hmoov nrog cov khoom me me

- Kev hloov pauv sai thiab yooj yim ntawm ob hom milling rau kev tsim cov hmoov sib txawv ntawm qhov ntau thiab tsawg

- Cov qauv airflow optimized kom tsis txhob satellite hais rau cov hmoov zoo

- Sau cov hmoov hlau qhuav nyob rau hauv ib lub pej thuam plua plav hauv qab tiv thaiv roj

- Sau cov nyiaj nplua los ntawm kev lim pneumatic

- Muaj peev xwm khaws ntau dua 100 qhov kev teeb tsa

- Cov cuab yeej tuaj yeem ua haujlwm nyob deb ntawm GSM chav tsev -

-11.jpg)

100 mesh - 400 mesh Hlau Powder Dej Atomizer Tshuab

Nws yog tsim nyog rau ua hmoov (los yog granular) cov ntaub ntawv nyob rau hauv lub atomizing tank tom qab melting hlau los yog hlau alloys (zoo ib yam li melting los yog nqus melting yuav siv tau).Feem ntau yog siv hauv cov tsev kawm ntawv qib siab, cov chaw tshawb fawb tshawb fawb, thiab lwm yam. Hlau atomization hmoov tuaj yeem tsim los ntawm kev kub siab dej atomization raws li daim ntawv thov hmoov.

Cov cuab yeej no kuj tsim nyog rau kev tsim khoom thiab kev tshawb fawb ntawm kev tsim khoom ntxiv (kub refining) hlau hmoov npaj hauv cov tsev kawm qib siab thiab cov koom haum tshawb fawb tshawb fawb.

Cov cuab yeej tseem tsim nyog rau kev tshawb fawb thiab tsim ntau yam stainless hlau, hlau alloy, tooj liab hmoov, txhuas hmoov, nyiaj hmoov, ceramic hmoov thiab brazing hmoov.

-

High Vacuum Nruam Casting Tshuab Rau Cov Khoom Tshiab Casting Bonding Kub Nyiaj Tooj Hlau Hlau

Casting ntawm cov khoom siv hluav taws xob xws li daim ntawv cog lus alloy nyiaj tooj liab hlau thiab high-purity tshwj xeeb xaim Kev tsim cov cuab yeej siv no yog ua raws li qhov xav tau tiag tiag ntawm qhov project thiab txheej txheem, thiab ua kom siv tag nrho cov cuab yeej siv niaj hnub high-tech.

1. Txais German high-frequency cua sov tshuab, tsis siv neeg zaus nrhiav thiab ntau yam kev tiv thaiv technology, uas yuav yaj nyob rau hauv ib tug luv luv lub sij hawm, txuag lub zog thiab ua hauj lwm zoo.

2. Hom kaw + inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab sib tov ntawm impurities.Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim.

3. Siv kaw + inert gas los tiv thaiv lub melting chamber.Thaum melting nyob rau hauv ib qho inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon pwm yog yuav luag negligible.

4. Nrog kev ua haujlwm ntawm electromagnetic stirring + mechanical stirring nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

5. Siv cov ntaub ntawv pov thawj yuam kev (tiv thaiv kev dag) tsis siv neeg tswj qhov system, kev ua haujlwm yooj yim dua.

6. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C).

7. HVCC series siab nqus nruam casting khoom yog nws tus kheej tsim thiab tsim, nrog cov cuab yeej siv siab heev, siv rau kev nruam nruam ntawm siab purity kub, nyiaj, tooj liab thiab lwm yam alloys.

8. Cov khoom siv no siv Mitsubishi PLC kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo tsav tsav thiab lwm yam khoom siv hauv tsev thiab txawv teb chaws.

9. Melting nyob rau hauv ib tug kaw + inert gas tiv thaiv melting chav tsev, muab ob npaug rau noj, electromagnetic stirring, mechanical stirring, tub yees, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj porosity, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

10. Nqus Hom: Lub tshuab nqus tsev siab.

-

Nqus Nruam Casting Tshuab rau Kub Nyiaj Copper Alloy

Cim lub tshuab nqus tsev nruam casting system

Rau siab tshaj plaws ntawm cov khoom semi-tiav:

Txhawm rau txo qhov kev pheej hmoo ntawm oxidation thaum lub sij hawm melting thiab thaum lub sij hawm kos duab, peb tsom ntsoov rau kev tsis txhob muaj cov pa oxygen thiab txo qhov kub thiab txias ntawm cov khoom siv hlau.

Nta kom tsis txhob muaj pa oxygen:

1. Inert gas system rau lub melting chamber

2. Lub tshuab nqus tsev rau lub melting chamber - tshwj xeeb muaj rau Hasung nqus nruam casting tshuab (VCC series)

3. Inert gas flushing ntawm qhov tuag

4. Optical tuag kub ntsuas

5. Ntxiv qhov cua txias thib ob

6. Tag nrho cov kev ntsuas no yog qhov zoo tshaj plaws rau cov alloys uas muaj tooj liab xws li kub liab los yog nyiaj, vim cov ntaub ntawv no nyiam oxidise yooj yim.Cov txheej txheem kos duab thiab qhov xwm txheej tuaj yeem pom tau yooj yim los ntawm kev soj ntsuam qhov rais.

Lub tshuab nqus tsev degrees tuaj yeem ua raws li cov neeg siv khoom thov.

-

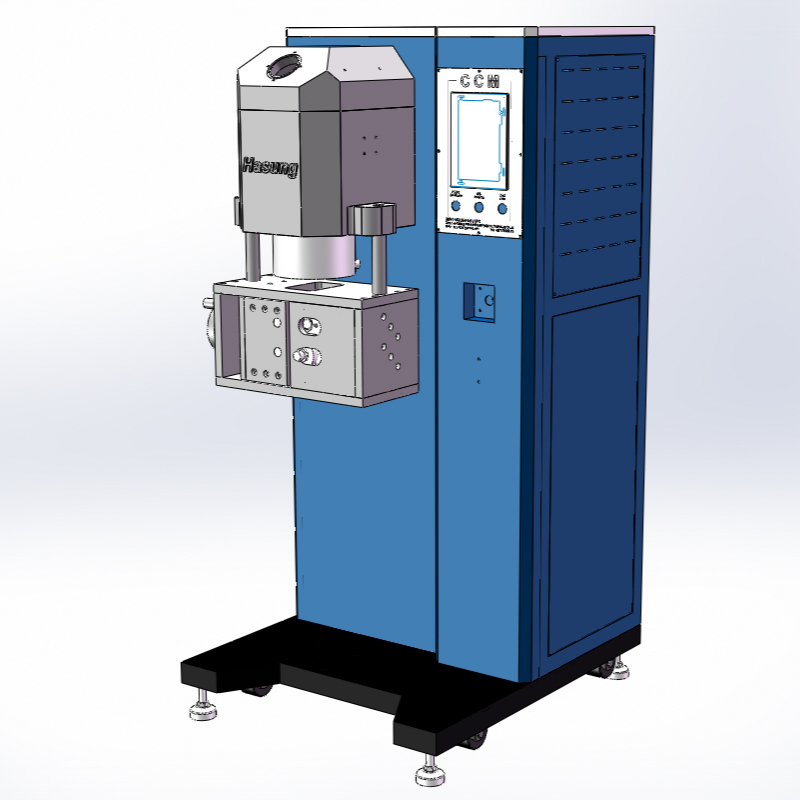

Nruam Casting Tshuab rau Kub Silver Copper Alloy

Kev tsim cov cuab yeej siv no yog ua raws li qhov xav tau tiag tiag ntawm qhov project thiab txheej txheem, siv cov cuab yeej siv niaj hnub high-tech.

1. Siv German high-frequency cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv technologies, nws yuav yaj nyob rau hauv ib tug luv luv lub sij hawm, lub zog txuag thiab kev tiv thaiv ib puag ncig, thiab ua hauj lwm efficiency.

2. Hom kaw + inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab tiv thaiv kev sib xyaw ntawm impurities.Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim.

3. Siv lub kaw + inert roj tiv thaiv melting chamber, melting thiab nqus tsev vacuuming tib lub sij hawm, lub sij hawm yog halved, thiab ntau lawm efficiency yog heev txhim khu kev qha.

4. Melting nyob rau hauv ib tug inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon crucible yuav luag negligible.

5. Nrog rau electromagnetic stirring muaj nuj nqi nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

6. Nws txais qhov yuam kev pov thawj (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim rau kev siv.

7. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C).HS-CC series nruam casting khoom yog tus kheej tsim thiab tsim nrog cov thev naus laus zis siab tshaj plaws thiab muaj nplooj siab rau melting thiab casting kub, nyiaj, tooj liab thiab lwm yam alloys strips, rods, nplooj ntawv, kav, thiab lwm yam.

8. Cov cuab yeej siv no siv Mitsubishi PLC kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo tsav tsav thiab lwm yam khoom lag luam muaj npe nrov hauv tsev thiab txawv teb chaws.

9. Melting, electromagnetic stirring, thiab tub yees nyob rau hauv ib tug kaw + inert gas tiv thaiv melting chav tsev, yog li ntawd cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj pores, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.