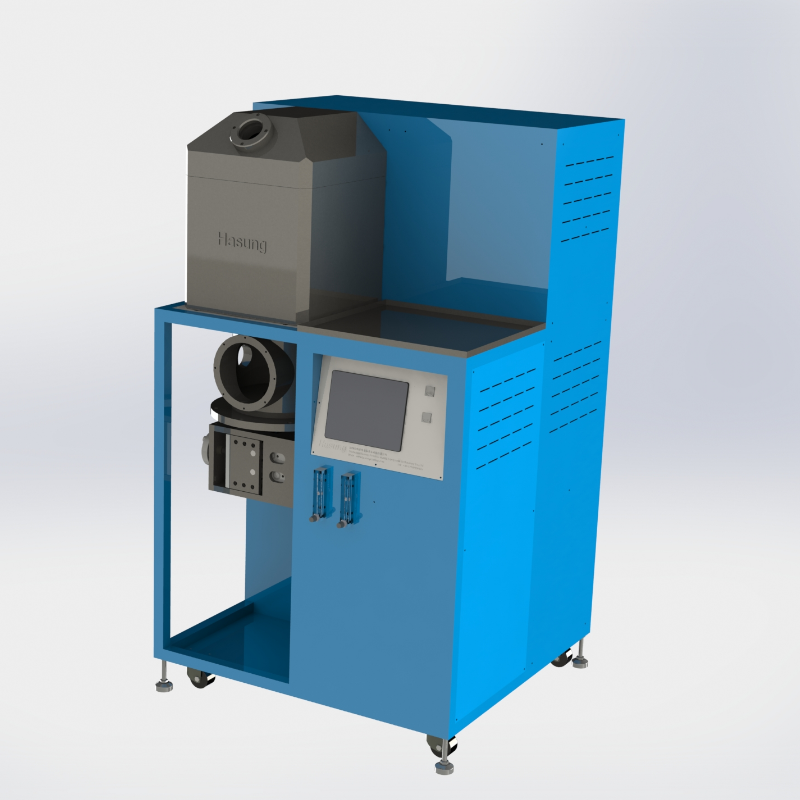

Lus piav qhia luv luv:

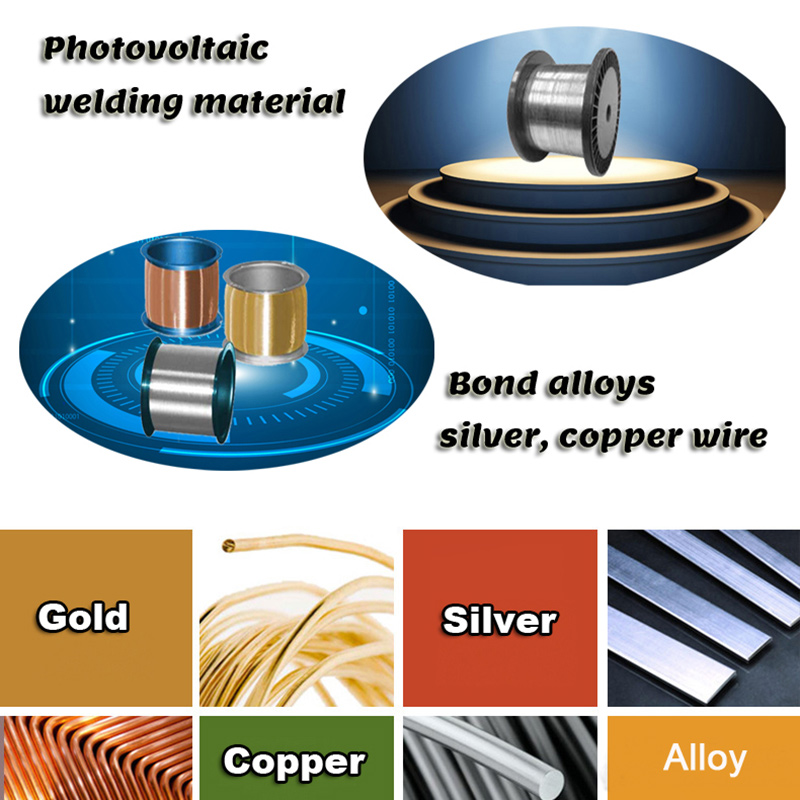

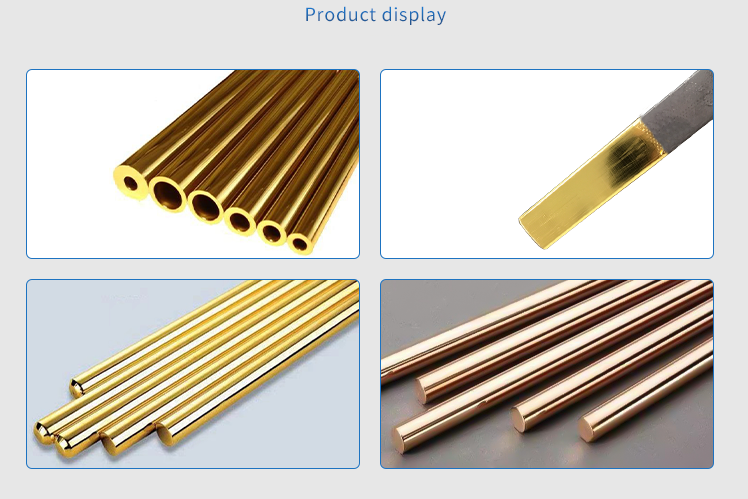

Casting ntawm cov khoom siv hluav taws xob xws li daim ntawv cog lus alloy nyiaj tooj liab hlau thiab high-purity tshwj xeeb xaim Kev tsim cov cuab yeej siv no yog ua raws li qhov xav tau tiag tiag ntawm qhov project thiab txheej txheem, thiab ua kom siv tag nrho cov cuab yeej siv niaj hnub high-tech.

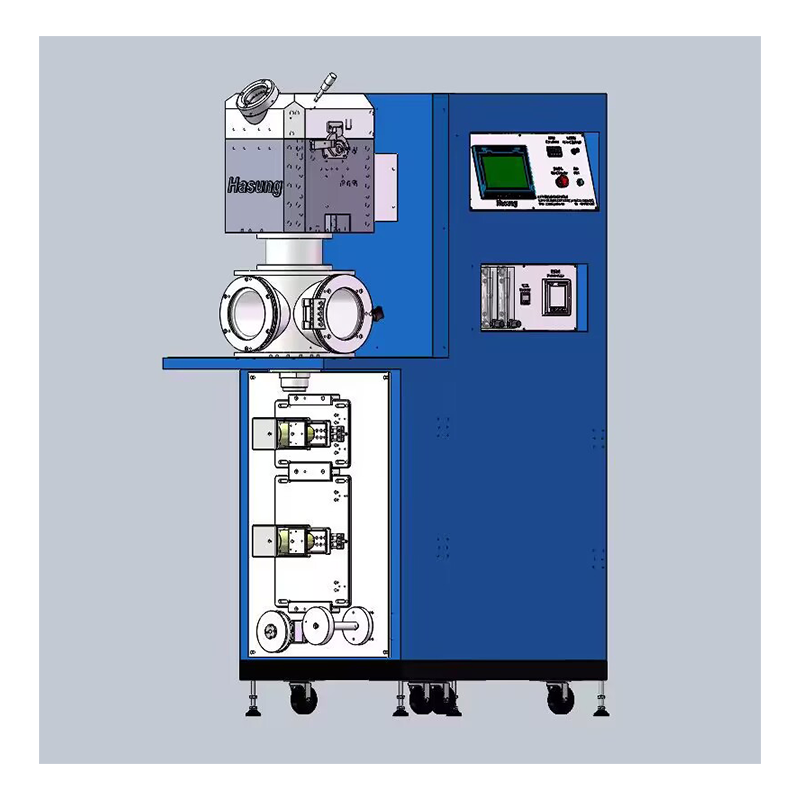

1. Txais German high-frequency cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv technology, uas yuav yaj nyob rau hauv ib tug luv luv lub sij hawm, txuag lub zog thiab ua hauj lwm zoo.

2. Hom kaw + inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab sib tov ntawm impurities. Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim.

3. Siv kaw + inert gas los tiv thaiv lub melting chamber. Thaum melting nyob rau hauv ib qho inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon pwm yog yuav luag negligible.

4. Nrog kev ua haujlwm ntawm electromagnetic stirring + mechanical stirring nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

5. Siv cov ntaub ntawv pov thawj yuam kev (tiv thaiv kev dag) tsis siv neeg tswj qhov system, kev ua haujlwm yooj yim dua.

6. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C).

7. HVCC series siab nqus nruam casting khoom yog nws tus kheej tsim thiab tsim, nrog cov cuab yeej siv siab heev, siv rau kev nruam nruam ntawm siab purity kub, nyiaj, tooj liab thiab lwm yam alloys.

8. Cov khoom siv no siv Mitsubishi PLC kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo tsav tsav thiab lwm yam khoom siv hauv tsev thiab txawv teb chaws.

9. Melting nyob rau hauv ib tug kaw + inert gas tiv thaiv melting chav tsev, muab ob npaug rau noj, electromagnetic stirring, mechanical stirring, tub yees, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj porosity, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

10. Nqus Hom: Lub tshuab nqus tsev siab.