Hmoov Atomization Nroj Tsuag

Ua Hlau HmoovCovPowderMetallurgy (PM) txheej txheem yog ua cov hmoov hlau.Cov hlauhmoov dej atomizeryog siv los tsim cov khoom zoo thiab homogenous master grains thiab alloy grains, thiab kuj cov hmoov, pib los ntawm raw khoom molten los ntawm induction cua sov nyob rau hauv ib tug tiv thaiv huab cua, thiab ces thaum casting hmoov, yuav txais yuav lub siab pressured phom phom kom tawg lub molten. hlau mus rau hauv zoo particles. Feem ntau, siv hauv kev lag luam hlau refining. The Gas Atomizer yogcharacterized los ntawm me me ib puag ncig muaj kuab paug, high degree ntawm pob-zoo hmoov hmoov, tsis tshua muaj oxygen cov ntsiab lus thiab ceev ceev cua txias thiab hais txog.Los ntawm ntau xyoo kev tsim kho tshiab thiab kev txhim kho, peb lub tuam txhab tau hloov kho peb cov roj atomization hmoov-tsim cov txheej txheem thiab thev naus laus zis ntau zaus txhawm rau tsim cov hmoov hlau thiab alloy ntawm kev ua haujlwm siab.Tam sim no, thev naus laus zis tau dhau los ua qhov tseem ceeb hauv kev txhawb nqa thiab txhawb nqa atomization hmoov-tsim khoom, kev tshawb fawb cov khoom tshiab thiab kev tsim kho tshiab.Lub hauv paus ntsiab lus ntawm kev ua haujlwm ntawm cov khoom siv atomizing yog hais txog cov hmoov-tsim cov txheej txheem uas smelting hlau los yog hlau nyob rau hauv tej yam kev mob nrog cov kua hlau poured obliquely rau cua sov preservation crucible ntws tawm los ntawm cov kua diversion qhov ncauj (downward), thiab yuav siv sij hawm kom zoo dua ntawm lub siab siab gases ntawm nozzle. txhawm rau txhuam cov kua hlau rau hauv qhov loj ntawm cov nplua thiab cov kua me me;Cov kua ya ya ua kom khov rau hauv pob-puab lossis sub-pob-zoo li hais thiab yog li ua tiav tag nrho cov hmoov-tsim txheej txheem.Feem ntau, siv hauv hlau 3D luam ntawv kev lag luam.

-

Hlau Flakes Ua Tshuab Kub Flakes Ua Khoom Siv Rau Kub Refining

Khoom Taw qhia:

1. Txais qhov nruab nrab zaus induction, lub sijhawm luv melting thiab kev ua haujlwm siab.

2. Lub melting chamber siv cov roj inert uas yog siv los tiv thaiv oxidation ntawm cov ntaub ntawv hlau thiab kev koom ua ke ntawm impurities.Rau lub hom phiaj no, nws yog tsim rau high-purity hlau cov ntaub ntawv los yog smelting uas yooj yim oxidized ntsiab.

3. Cov neeg kho tshuab stirring muaj nuj nqi nyob rau hauv lub nqus tsev vacuum yog saws, thiab cov xim tsim tsis segregated.

4. Lub smelting yog tiv thaiv los ntawm high-purity inert gas, yog li cov graphite ruthenium muaj oxidation tsawg heev.

5. Siv tsis siv neeg Nyiv Mitsubishi PLC maub los, kev ua haujlwm yooj yim.

6. Cov pwm yog cia li rhuab thaum lub sij hawm pouring txheej txheem los xyuas kom meej qhov zoo ntawm cov casting.

7. Nrog ntau lub ntiaj teb nto moo hom khoom kom paub meej zoo.8. Feem ntau yog siv rau kev kho kub.

-

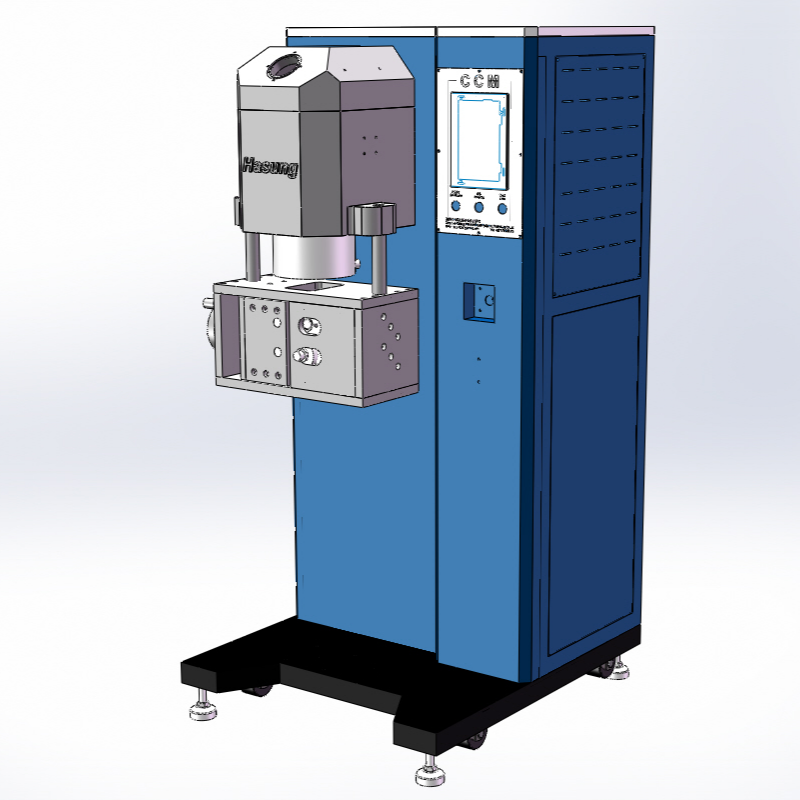

Hlau hmoov Dej Atomizer Rau Precious Hlau Powder Kub Silver Copper

Khoom Specifications

Induction cua sov nyob rau hauv kev tiv thaiv ntawm inert roj, siv graphite crucible, melting kub mus txog 1600 degrees.HT kub hom tuaj yeem siv tau, siv cov ceramic crucible (graphite susceptor), qhov kub ntawm qhov kub tuaj yeem ncav cuag 2000 degrees.Lub tshuab hluav taws xob kub tuaj yeem muab ntxiv, qhov twg cov roj tau rhaub rau 500 degrees rau kev tsim cov hmoov hlau zoo dua.Cov cuab yeej tsim cov hmoov hlau kheej kheej nrog cov dej ntws zoo thiab qhov loj me ntawm 10 thiab 200 microns, ntau dua mus txog # 400, 500 #.Nws tuaj yeem siv rau hauv kev tsim khoom xws li laser xaiv sintering thiab hmoov metallurgy.Qhov zoo ntawm Hasung AU series khoom:

- Compact qauv thiab ua haujlwm yooj yim

- Yooj yim thiab ua tau zoo ntawm cov khoom me me ntawm cov hmoov hlau

- Yooj yim thiab ceev alloy hloov thiab hloov nozzle

- Cov hmoov nplej siab heev thiab milling poob tus nqi qis li 1/1000

- Cov txheej txheem tsim khoom ruaj khovCov yam ntxwv tseem ceeb ntawm Hasung AU Series Devices:

- Graphite crucible tuaj yeem ua kom sov txog 2000 degrees hauv qhov chaw tiv thaiv roj

- Microprocessor tswj induction lub cev muaj zog (400 volts, 3 theem zog)

- Cov kua hlau sib xyaw ua haujlwm zoo heev, uas tuaj yeem fuse thiab smelt sib txawv hlau ua ntej roj atomization

- Nyob rau hauv ib puag ncig ntawm kev tiv thaiv roj, lub tshuab pub mis tuaj yeem muab ntxiv los hloov cov alloy muaj pes tsawg leeg

- Tswj qhov kub thiab txias siv N-hom thiab S-hom thermocouples

- Crucible muaj peev xwm 1500cm3, 3000cm3 thiab 12000cm3 yeem

- Siv argon lossis nitrogen mus txog 30 cua

- Lub tshuab cua sov tuaj yeem muab ntxiv los ua kom sov cov roj rau 500 degrees rau kev tsim cov hmoov nrog cov khoom me me

- Kev hloov pauv sai thiab yooj yim ntawm ob hom milling rau kev tsim cov hmoov sib txawv ntawm qhov ntau thiab tsawg

- Cov qauv airflow optimized kom tsis txhob satellite hais rau cov hmoov zoo

- Sau cov hmoov hlau qhuav nyob rau hauv ib lub pej thuam plua plav hauv qab tiv thaiv roj

- Sau cov nyiaj nplua los ntawm kev lim pneumatic

- Muaj peev xwm khaws ntau dua 100 qhov kev teeb tsa

- Cov cuab yeej tuaj yeem ua haujlwm nyob deb ntawm GSM chav tsev -

-11.jpg)

100 mesh - 400 mesh Hlau Powder Dej Atomizer Tshuab

Nws yog tsim nyog rau ua hmoov (los yog granular) cov ntaub ntawv nyob rau hauv lub atomizing tank tom qab melting hlau los yog hlau alloys (zoo ib yam li melting los yog nqus melting yuav siv tau).Feem ntau yog siv hauv cov tsev kawm ntawv qib siab, cov chaw tshawb fawb tshawb fawb, thiab lwm yam. Hlau atomization hmoov tuaj yeem tsim los ntawm kev kub siab dej atomization raws li daim ntawv thov hmoov.

Cov cuab yeej no kuj tsim nyog rau kev tsim khoom thiab kev tshawb fawb ntawm kev tsim khoom ntxiv (kub refining) hlau hmoov npaj hauv cov tsev kawm qib siab thiab cov koom haum tshawb fawb tshawb fawb.

Cov cuab yeej tseem tsim nyog rau kev tshawb fawb thiab tsim ntau yam stainless hlau, hlau alloy, tooj liab hmoov, txhuas hmoov, nyiaj hmoov, ceramic hmoov thiab brazing hmoov.