VCT Series Nqus Siab Casting Tshuab nrog PLC kov npo

Nta

1. Txoj kev ua haujlwm: Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system.

2. Tswj system: Mitsubishi PLC + Tib neeg-tshuab interface ntse tswj system (yeem).

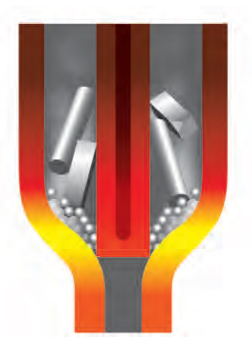

3. Siv German high-frequency cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv technologies, nws yuav yaj nyob rau hauv ib tug luv luv lub sij hawm, lub zog txuag, thiab ua hauj lwm efficiency.

4. Cov hom kaw / channel hom + lub tshuab nqus tsev / inert roj tiv thaiv lub tshuab melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab kev sib xyaw ntawm impurities. Cov khoom siv no yog tsim rau cov khoom siv high-purity hlau los yog cov hlau hlau uas yooj yim oxidized.

5. Txais yuav kaw / channel hom + lub tshuab nqus tsev / inert gas los tiv thaiv lub melting chamber, melting thiab txias yog ua nyob rau tib lub sij hawm, lub sij hawm yog halved thiab ntau lawm efficiency yog nce.

6. Melting nyob rau hauv ib tug inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon pwm yuav luag negligible.

7. Nrog lub tshuab hluav taws xob nplawm ua haujlwm nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj kev sib cais ntawm cov xim.

8. Nws txais qhov yuam kev pov thawj (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim dua rau kev siv.

9. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C).

10. HS-VCT kub thiab nyiaj casting cov khoom siv / puv-automatic ntau lawm kab yog ntawm nws tus kheej tsim thiab tsim nrog cov khoom siv qib siab tshaj plaws rau kev smelting thiab casting kub, nyiaj, tooj liab thiab lwm yam alloys.

11. Cov khoom siv no siv Mitsubishi PLC kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo tsav tsav thiab lwm yam khoom siv hauv tsev thiab txawv teb chaws.

12. Melting, electromagnetic stirring, thiab tub yees nyob rau hauv lub kaw / channel + lub tshuab nqus tsev / inert gas tiv thaiv melting chav tsev, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsis tshua muaj poob, tsis muaj porosity, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

Vim li cas koj thiaj xaiv Hasung Nqus Siab Casting Tshuab?

Hasung Nqus Casting Tshuab piv rau lwm lub tuam txhab

1. Kev txuag hluav taws xob. Nrog qis zog noj ntawm 5KW 220V ib theem.

2. Zoo melting ceev. Melting ceev yog nyob rau hauv 2 feeb uas yog ceev raws li lwm tus neeg lub tshuab ntawm 8W 380V.

3. 1kg lossis 2kg muaj peev xwm tuaj yeem nruab nrog 220V ib theem uas tsim nyog rau cov neeg siv khoom uas tsis muaj 380V 3 theem hluav taws xob. Lub zog loj 5KW, casting ntau hauv 18 kt txog 2,000 g. 380V 8KW yog xaiv tau uas melting ceev ceev.

4. Hasung thawj qhov chaw yog los ntawm cov neeg paub zoo hauv Nyij Pooj thiab German hom.

Technical Parameters

| Qauv No. | HS-TVC 1 | HS-VCT 2 |

| Qhov hluav taws xob | 220V, 50/60Hz 1P / 380V, 50/60Hz 3P | 380V, 50/60Hz 3 P |

| Hwj chim | 5KW / 10KW TSI | 10 KW |

| Max. temp. | 1500 ° C | |

| Melting ceev | 1-2 feeb. rau 380V, 3-6 min. rau 220v. | 3-5 feeb. rau 380V, 8-15 min. rau 220v. |

| Casting siab | 0.1Mpa - 0.3Mpa, 100 Kpa - 300 Kpa, 1 Bar - 3 Bar (kho tau) | |

| Peev xwm (kub) | 1kg ua | 2kg ua |

| Max. lub tog raj kheej loj | 4" x 10" | 5" x 12" |

| Kev siv hlau | Kub, K kub, nyiaj, tooj liab, alloy | |

| Lub tshuab nqus tsev siab | Muaj | |

| Argon siab teeb tsa | Muaj | |

| Kev ntsuas kub | Muaj | |

| Pouring lub sij hawm teem | Muaj | |

| Kev teeb tsa lub sijhawm siab | Muaj | |

| Siab tuav lub sij hawm teem | Muaj | |

| Nqus sij hawm teem caij | Muaj | |

| Kev tiv thaiv overheat | Yog lawm | |

| Sib nqus stirring | Yog lawm | |

| Flask lifting qhov siab adjustable | Muaj | |

| Txawv lub raj mis txoj kab uas hla | Muaj, siv cov flanges sib txawv | |

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | |

| Tswj qhov system | Taiwan / Siemens PLC kov vaj huam sib luag | |

| Hom kev ua haujlwm | Automatic hom / Phau ntawv hom (ob leeg) | |

| Inert gas | Nitrogen / argon (yeem) | |

| Hom cua txias | Dej ntws / Dej chiller (muag nyias) | |

| Lub tshuab nqus tsev twj | Kev ua haujlwm siab lub tshuab nqus tsev twj (nrog) | |

| Qhov ntev | 780 * 720 * 1200 hli | |

| Qhov hnyav | kwv yees. 120kg (lub tshuab nqus tsev twj kwv yees li 29kg) | |

Khoom Qhia

Khoom Qhia

VCT Series lub tshuab nqus tsev siab casting tshuab yog nruab nrog Mitsubishi PLC kov vaj huam sib luag, koj tuaj yeem siv phau ntawv ua haujlwm ib kauj ruam los yog tsis siv neeg ua haujlwm rau casting. Nrog PLC kov vaj huam sib luag, tsis muaj xws li qhov kub thiab txias, lub tshuab nqus tsev, lub sijhawm nqus tsev, lub sijhawm nchuav, siab, thiab lwm yam tuaj yeem pom tau yooj yim.

VCT induction nqus siab casting tshuab yog xaiv los nruab nrog kev co uas tso cai rau koj kom muaj txiaj ntsig zoo dua, tshwj xeeb tshaj yog rau koj cov khoom nyias nyias, Karat kub jewellery. Nws yog tib yam ua haujlwm raws li TVC qauv, qhov sib txawv tsuas yog cov qauv thiab lub tshuab me me.

Nrog Mitsubishi PLC kov vaj huam sib luag, yooj yim tab sis kev ua haujlwm zoo.

* Koj tuaj yeem ua phau ntawv casting lossis tag nrho tsis siv neeg casting.

* Koj tuaj yeem teeb tsa qhov ntsuas ntawm koj tus kheej raws li koj cov khoom nta.

* Koj tuaj yeem teeb tsa cov khoom pov tseg los ntawm koj tus kheej.

Lub tshuab casting siv lub teb chaws Yelemees Infineon IGBT induction cua sov tshuab, Lub teb chaws Yelemees Schneider electrics, Lub teb chaws Yelemees Omron, Nyiv Mitsubishi electrics, Nyiv Panasonic pab tsav, Nyiv SMC, thiab lwm yam.

Siv cov khoom siv zoo, zoo craftmanship.

Lub tshuab nqus tsev siab casting tshuab consumables:

1. Graphite crucible

2. Ceramic gasket

3. Ceramic tsho

4. Graphite stopper

5. Thermocouple

6. Cua sov kauj

7. Lim

8. Gaskets

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur