Qhov Hom Kub Ingot Nqus Casting System

Kev daws teeb meem

Nyob rau hauv xyoo tas los no, kev ua lag luam ntawm kev nqis peev uas muaj nuj nqis hlau tau dhau los ua ntau thiab xav tau: tam sim no lub ingot yuav tsum muaj cov khoom zoo nkauj ntawm lub pob zeb.

Siv cov tshuab muaj nyob rau hauv kev ua lag luam ua ntej tshaj tawm HS-VF260, ib tus tuaj yeem tsim cov khoom tsim nyog, tab sis nws nyuaj rau cov neeg ua haujlwm tswj lawv. Raws li qhov tseeb, calibration ntawm kev ua haujlwm tsis ua haujlwm thiab kev saib xyuas zoo tib yam yuav luag tsuas yog txwv rau cov neeg ua haujlwm tshwj xeeb.

Lub community launch ntawm HS-VF260 revolutionized teb: tuam txhab uas muag thoob plaws lub ntiaj teb no tau muab nrog tailored tunnel furnaces, scalable raws li ntau lawm hom (ingot los ntawm 1 ooj, mus txog 400 ounces los yog 1000 ounces), uas nws cov txij nkawm yog siv tau.

Qhov kev daws teeb meem nkaus xwb yog tsim lub qhov cub induction nrog ib qho yooj yim thiab cov neeg siv-phooj ywg interface (HMI kov npo), uas tuaj yeem raug tshem tawm tag nrho nrog tsuas yog ib tus ciaj ntswj.

Cov teeb meem tseem ceeb thiab qhov tsis zoo ntawm Txoj Cai Lij Choj

Lub cub tawg yog nyob rau hauv qhov qhib cua thiab cov nplaim taws ib txwm kub hnyiab, yog li kev pheej hmoo ntawm kev sib tsoo ntawm kev ua haujlwm yog siab heev.

Kev pheej hmoo siab dua ntawm cov hlau poob.

Qhov tseem ceeb emission ntawm fumes, uas nws rov qab yog kim heev rau lub tuam txhab, thiab kev loj hlob ntawm ib tug muaj zog electromagnetic teb.

Ntau yam khoom siv, xws li crucibles, yog siv thiab hnav tawm sai sai, implying cov nqi khiav lag luam siab.

Qhov zoo ntawm cov khoom tiav (shininess, purity, flatness) yog nruab nrab-siab.

Lub tshuab hluav taws xob yuav tsum muaj cov neeg ua haujlwm tas li.

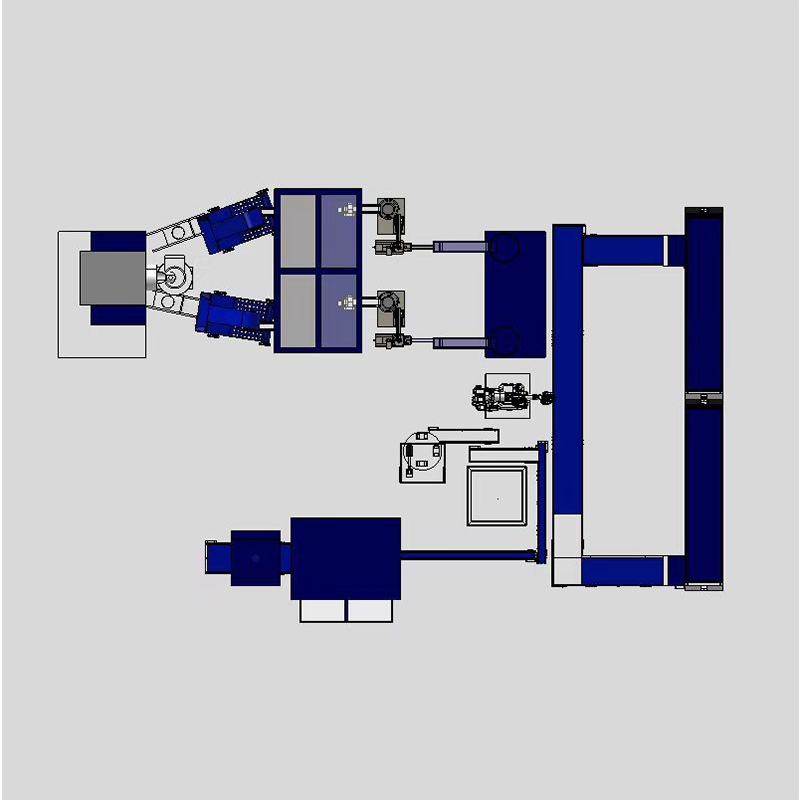

Qhov cub kub Nqus Casting System

Productivity: 4 blocks / teev, txhua qhov hnyav 15kg;

Ua haujlwm kub siab tshaj plaws: 1350-1400 ° C;

Hom kev tiv thaiv roj: nitrogen; Cua noj: 5 / H;

Rauv inlet dej kub thiab generator: mus txog 21 degrees Celsius;

Kev siv dej tag nrho: 12-13 / H;

Yuav tsum tau txias dej siab: 3 mus rau 3,5 bar;

Cua txaus rau qhov cua: 0.1 m / s;

Yuav tsum tau cua siab los ntawm lub cub tawg: 6 bar;

Daim ntawv qhia hom thiab cais: Graphite 400 oz;

Tag nrho cheeb tsam ntawm lub cub tawg installation yog 18.2M2, qhov ntev yog 26500mm, thiab qhov dav yog 2800mm.

Lub melting tunnel node yog tswj los ntawm cov chaw hauv qab no / chaw ua haujlwm:

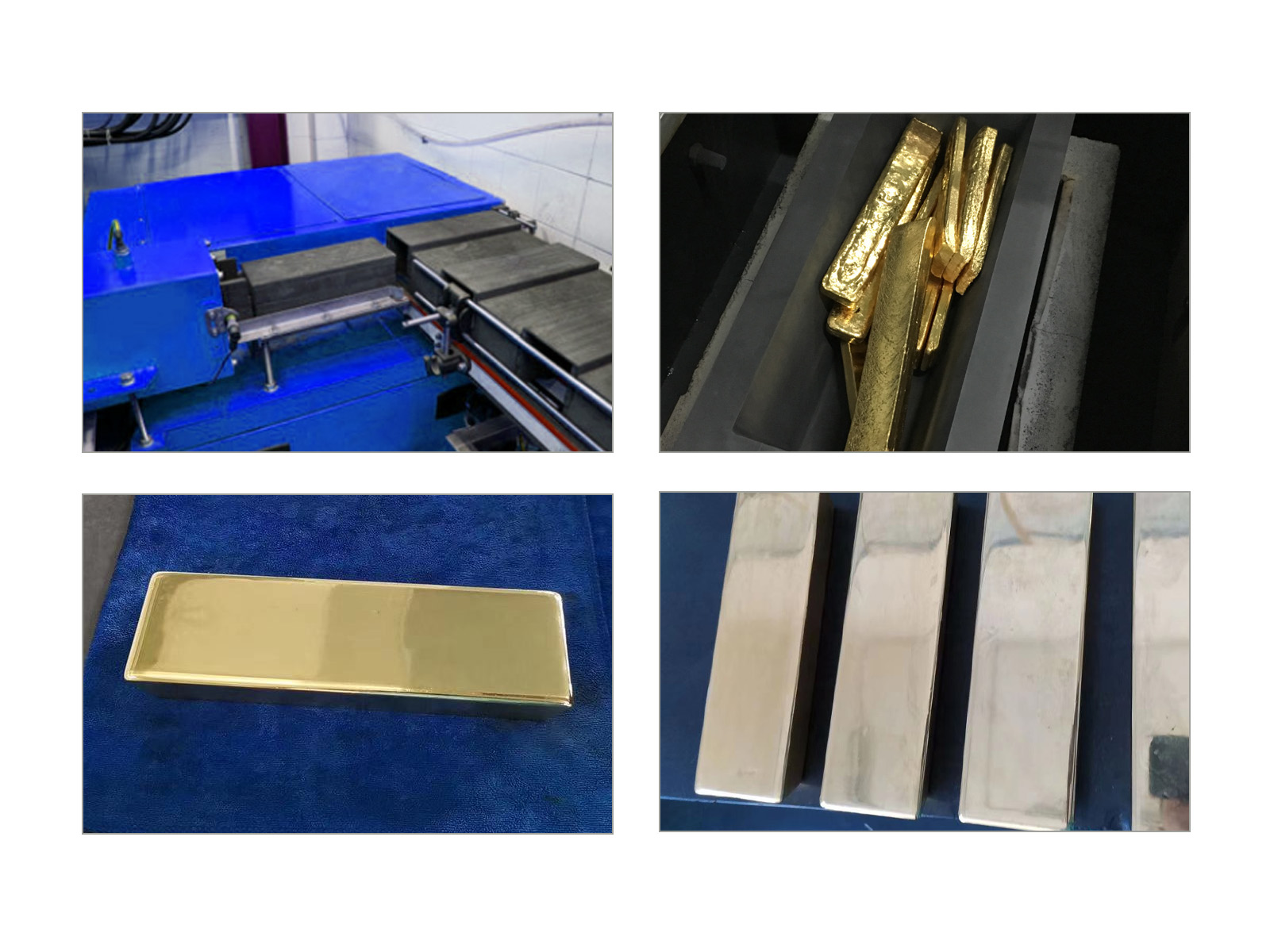

Tsim los ntawm stainless hlau. Daim ntawv thov: Txhawm rau ntim cov khoom kub rau hauv cov ntawv graphite. Main

Cheebtsam: Hluav taws xob thawb-kauj ruam ntaus ntawv hloov chaw.

Input parameter cheeb tsam Siv:

Txwv cov huab cua sab nraum zoov los ntawm kev nkag mus rau hauv lub qhov txias txias: dej Lub ntsiab Cheebtsam: txawb muab faib nrog pneumatic tswj, nozzle Txhaj nitrogen.

Kev siv thaj chaw melting:

siv rau smelting kub hais txias system: dej Lub ntsiab Cheebtsam: inductor lined nrog refractory cement, infrared

Kub sensor, nitrogen xa system

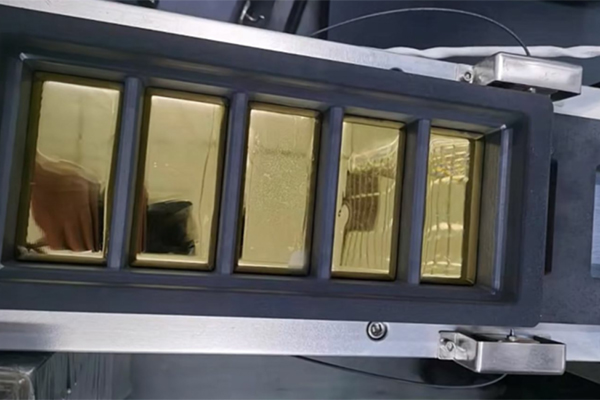

Qhov chaw txias txias:

muab faib nrog pneumatic tswj, nozzle Txhaj nitrogen. thiab nqus tsev vacuum.

Unloading cheeb tsam:

Tsim los ntawm stainless hlau. Lub hom phiaj:

Extract cov khoom tiav los ntawm daim ntawv qhia.

Fais fab Module, Zuag qhia tag nrho Module: Fais fab mov: 380v, 50Hz; 3 Phase Generator zog:

60 kW; lwm tus yog 20KW. Tag nrho lub zog yuav tsum tau: 80KW

Tswj Zone:

Chaw ua haujlwm rau txhua qhov cub

Khoom Qhia

Dab tsi yog tag nrho tsis siv neeg qhov cub kub kub bar ntau lawm kab?

Tag nrho tsis siv neeg qhov cub kub bar ntau lawm kab: revolutionizing lub kub kev lag luam

Kev lag luam kub ib txwm yog lub cim ntawm kev nplua nuj thiab kev vam meej, thiab kev thov rau kub tuav txuas ntxiv mus. Raws li kev siv thev naus laus zis, kev tsim cov khoom kub tau hloov pauv ntau. Ib qho ntawm cov kev tsim kho tshiab tshaj plaws hauv kev lag luam yog cov khoom siv hluav taws xob tag nrho qhov cub kub bar ntau lawm kab. Qhov kev siv thev naus laus zis no tau hloov pauv txoj kev kub hnyiab tau tsim, txhim kho efficiency, precision thiab zoo. Nyob rau hauv tsab xov xwm no, peb yuav tshawb xyuas seb lub qhov cub hluav taws xob tag nrho cov kab hluav taws xob kub yog dab tsi, nws ua haujlwm li cas, thiab nws cuam tshuam rau kev lag luam kub.

Dab tsi yog qhov siab tsis siv neeg qhov cub kub kub bar ntau lawm kab?

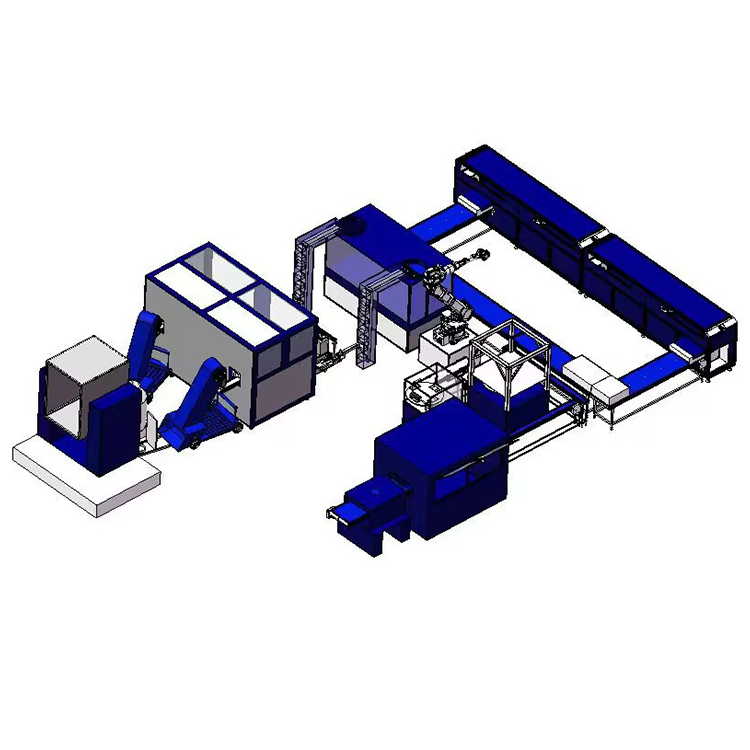

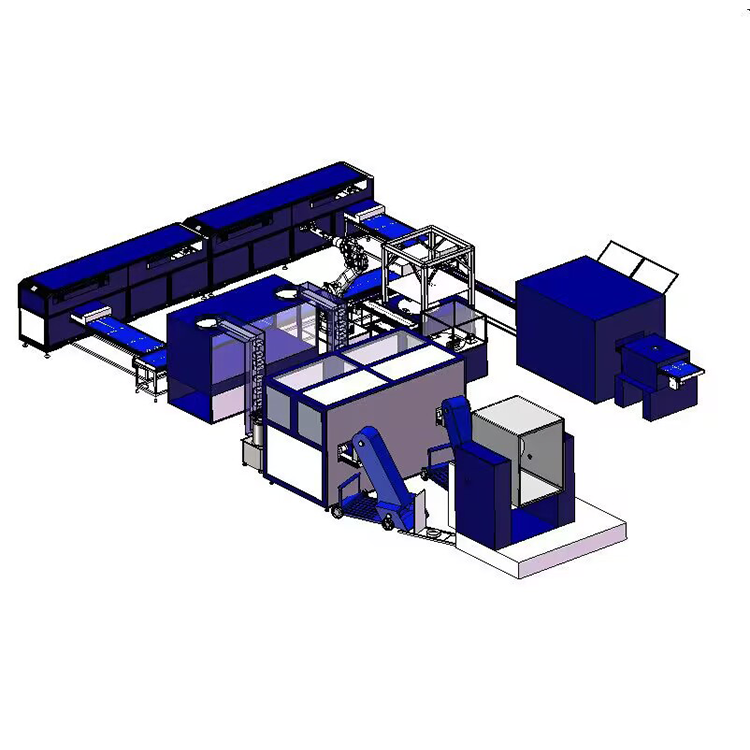

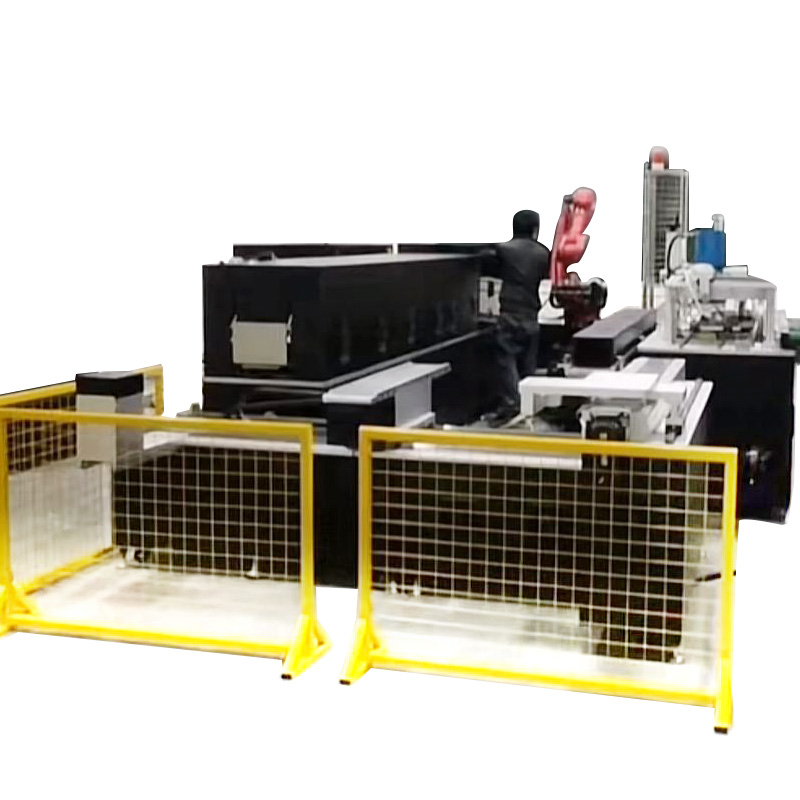

Lub siab tsis siv neeg qhov cub kub bar ntau lawm kab yog ib qho kev tshaj lij tshwj xeeb uas tsim los rau cov khoom siv kub kub. Nws muaj cov tshuab sib txuas sib txuas thiab cov cuab yeej siv ua haujlwm sib txuas ua ke los hloov cov ntaub ntawv raw rau hauv cov khoom kub tiav. Tag nrho cov txheej txheem yog tag nrho automated yam tsis muaj kev cuam tshuam phau ntawv, txo qhov kev pheej hmoo ntawm tib neeg yuam kev.

Ib qho tseem ceeb ntawm txoj kab yog lub qhov cub hluav taws xob, uas yog lub cub tawg tshwj xeeb tsim los kom yaj thiab ua kom zoo kub. Lub tshuab hluav taws xob tau nruab nrog qhov ntsuas kub siab tshaj plaws thiab cov ntsuas ntsuas kom ntseeg tau meej thiab zoo ib yam ntawm cov khoom kub. Tsis tas li ntawd, cov kab ntau lawm suav nrog ntau yam conveyors, pwm, tshuab cua txias thiab tswj cov txheej txheem kom ua tau zoo rau tag nrho cov txheej txheem tsim khoom.

Lub qhov cub kub kub nyiaj bar ntau lawm kab suav nrog

1. Hlau granulator

2. Sieving nrog vibration system thiab tshuab ziab khaub ncaws

3. Hloov lub tshuab nqus tsev

4. Dosing system

5. Qhov kub bar casting system

6. Ntxuav thiab polishing system

7. Dot marking system

8. Logo stamping

9. Ntim qhov system

Nws ua haujlwm li cas?

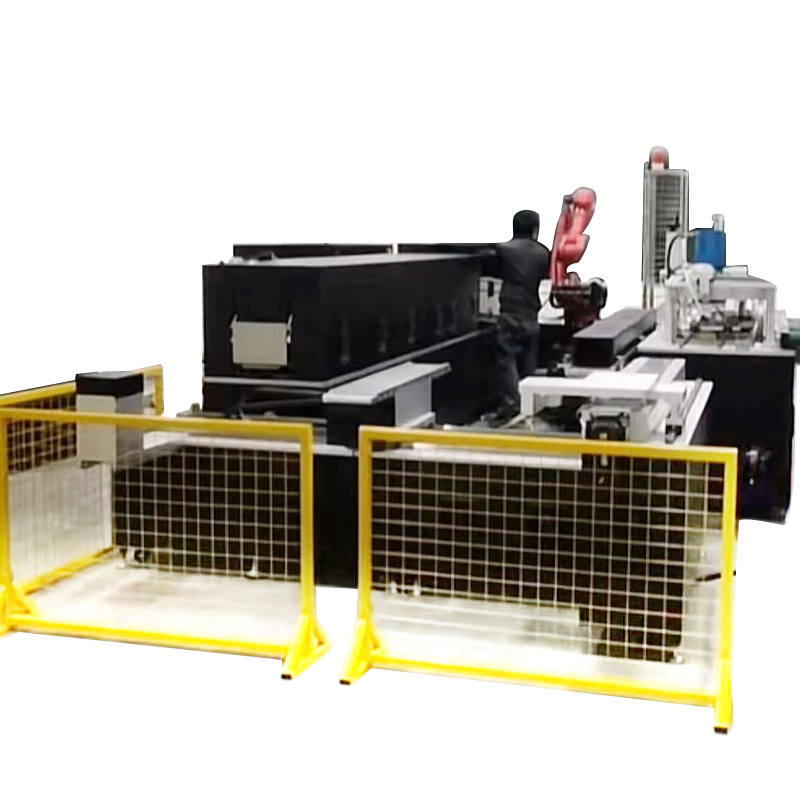

Lub siab automated qhov cub kub bar ntau lawm kab ua hauj lwm los ntawm ib tug series ntawm interrelated theem, txhua tus tsim los ua ib tug tshwj xeeb txoj hauj lwm nyob rau hauv lub kub bar manufacturing txheej txheem. Cov txheej txheem pib los ntawm kev thauj cov khoom kub kub rau hauv lub qhov cub, qhov chaw uas nws yog melted thiab refined kom tshem tawm impurities. Qhov kub thiab lub sijhawm ntawm cov cua sov yog ua tib zoo tswj kom ua tiav qhov xav tau purity thiab sib xws ntawm cov kub molten.

Tom qab cov khoom siv kub tau ua kom zoo, nws yog nchuav rau hauv pwm thiab zoo li tus yam xav tau kub bar. Cov pwm yog tsim los tsim cov khoom kub ntawm ntau qhov ntau thiab tsawg thiab qhov hnyav kom tau raws li kev xav tau ntawm kev ua lag luam. Tom qab cov kub solidifies, nws raug xa mus los ntawm ib tug txias system kom stabilize nws cov qauv thiab kub.

Kev tswj xyuas zoo yog ib qho tseem ceeb ntawm cov kab ntau lawm, nrog rau kev tshuaj ntsuam xyuas cov txheej txheem ua ke kom ntseeg tau tias cov khoom kub ua tau raws li cov qauv siab tshaj plaws ntawm purity thiab zoo. Txhua qhov sib txawv lossis qhov tsis xws luag raug txheeb xyuas tam sim thiab daws teeb meem, kom ntseeg tau tias tsuas yog cov khoom kub zoo meej raug tsim.

Kev cuam tshuam rau kev lag luam kub

Kev taw qhia ntawm lub siab tsis siv neeg qhov cub kub bar ntau lawm kab tau muaj kev cuam tshuam loj heev rau kev lag luam kub. Lub tshuab thev naus laus zis no tau hloov kho cov txheej txheem tsim khoom, xa ntau yam txiaj ntsig tseem ceeb uas tau hloov kho kev lag luam.

Ua ntej thiab foremost, automation ntawm cov txheej txheem ntau lawm ho nce efficiency thiab productivity. Nrog kev cuam tshuam me me, cov kab tuaj yeem ua haujlwm tsis tu ncua, ua kom cov zis ntau thiab txo lub sijhawm ntau lawm. Qhov no tso cai rau cov kub refiners thiab cov tuam txhab tsim khoom kom tau raws li qhov kev thov loj hlob rau cov khoom kub zoo dua thiab ua tau zoo.

Tsis tas li ntawd, qhov precision thiab sib xws ua tiav los ntawm automation txhim kho qhov zoo ntawm cov khoom kub tsim. Cov txheej txheem ntsuas kub siab tshaj plaws thiab cov txheej txheem ntsuas kev ua tau zoo kom ntseeg tau tias cov khoom kub ua tau raws li cov qauv purity siab tshaj plaws, txhawb kev ntseeg siab rau cov neeg siv khoom thiab cov tub ua lag luam.

Tsis tas li ntawd, lub siab tsis siv neeg qhov cub kub bar ntau lawm kab txhim kho kev nyab xeeb thiab txo qhov cuam tshuam ib puag ncig ntawm kub bar manufacturing. Los ntawm kev txo qis tib neeg kev koom tes hauv cov txheej txheem tsim khoom, kev pheej hmoo ntawm kev raug mob thiab kev raug mob raug txo kom tsawg. Tsis tas li ntawd, kev siv hluav taws xob zoo thiab cov peev txheej hauv cov kab ntau lawm ua rau muaj txiaj ntsig zoo dua thiab ib puag ncig zoo rau kev tsim khoom kub.

Tsis tas li ntawd, kev siv cov thev naus laus zis no ua rau cov tuam txhab kub kub sib tw hauv kev lag luam thoob ntiaj teb. Lub peev xwm los tsim cov khoom kub zoo ntawm tus nqi nrawm dua ua rau lawv muaj txiaj ntsig zoo, tso cai rau lawv kom ua tau raws li cov kev xav tau ntawm cov neeg yuav khoom thoob ntiaj teb thiab nthuav lawv cov lag luam mus txog.

Nyob rau hauv cov ntsiab lus, tag nrho automated qhov cub kub bar ntau lawm kab sawv cev rau ib qho tseem ceeb ua ntej rau kev lag luam kub. Nws cov txheej txheem kev tsim khoom siv tau zoo thiab meej txhim khu kev ua tau zoo, zoo thiab kev sib tw ntawm kub bar ntau lawm. Raws li qhov kev thov rau kub tseem nce ntxiv, cov thev naus laus zis tshiab no yuav ua lub luag haujlwm tseem ceeb hauv kev ua kom tau raws li kev xav tau ntawm kev lag luam thiab tsim lub neej yav tom ntej ntawm kev lag luam kub.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur