Video Qhia

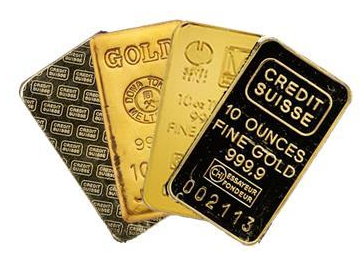

Hasung ua ib tus kws tshaj lij hlau npib minting kev daws teeb meem, tau tsim ntau lub npib ua kab thoob ntiaj teb. Lub npib hnyav li ntawm 0.6g mus rau 1kg kub nrog puag ncig, square, thiab octagon duab. Lwm cov hlau kuj muaj xws li nyiaj thiab tooj liab.

Koj tuaj yeem tso nyiaj nrog Hasung los muab kev daws teeb meem rau kojnpib minting kab. Cov pob khoom tsim muaj xws li kev taw qhia ntawm qhov chaw, cov khoom siv minting npib, thiab cov kws tsim khoom los pab koj ntsuas cov txheej txheem. Peb cov engineers tau koom nrog hauv cov txheej txheem kub ua cov kev tshawb fawb thiab tau ua tus kws pab tswv yim rau cov mint paub zoo.

Hasung tsom ntsoov rau kev daws cov teeb meem minting npib thaum muab cov lus qhia ua ntu zus ntawm cov hlau muaj txiaj ntsig. Rau 20+ xyoo peb tau nyob rau hauv lub forefront ntawm kub thiab nyiaj npib ua tshuab, peb muaj kev cob qha engineering kev pab cuam, on-site kev cob qhia, thiab kev pab txhawb nqa.

Thov niasnruam casting tshuab thiab dov tshuabsaib cov ntsiab lus.

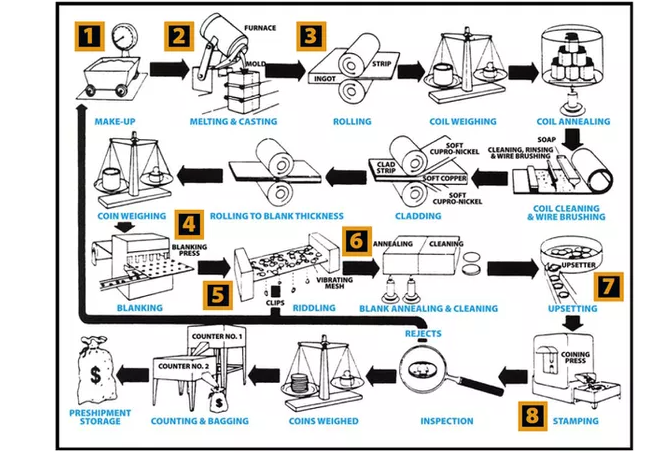

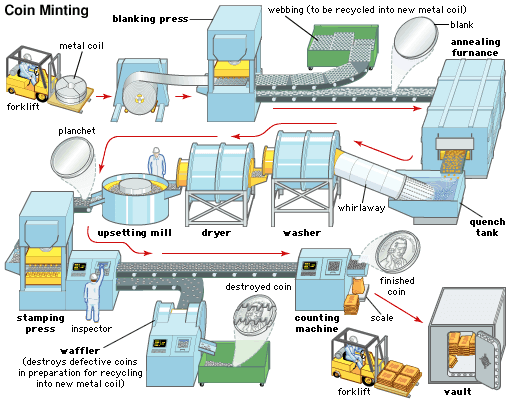

Cov npib ua li cas?

Cov txheej txheem siv los ua npib tau hloov zuj zus mus rau xyoo. Cov npib tau ua thawj zaug hauv lub nceeg vaj thaum ub ntawm Lydia zoo tshaj li ob txhiab xyoo dhau los. Cov txheej txheem minting rau npib thaum ub tau yooj yim heev. Ua ntej, ib pob me me ntawm kub, nyiaj, lossis tooj liab tau muab tso rau ntawm ib lub npib tuag kos rau hauv ib qho khoom zoo li pob zeb. Tom qab ntawd tus neeg ua haujlwm yuav muab ib lub npib thib ob tuag, muab tso rau saum, thiab ntaus nws nrog rauj loj.

Medieval mints siv preformed round discs ntawm hlau thiab ib tug ntsia hlau xovxwm los tsim cov nyiaj npib. Txawm hais tias qhov no yog txheej txheem phau ntawv, nws tau yooj yim dua thiab tau txais txiaj ntsig zoo dua li cov txheej txheem minting thaum ub.

Cov npib niaj hnub yog minted nrog hydraulic coining presses uas cia li pub cov blanks rau hauv lub tshuab. Thaum lub tshuab ua haujlwm tag nrho, cov xovxwm tuaj yeem ua tau ntau dua 600 npib ib feeb. Qhov kev nrawm no yog qhov tsim nyog rau kev ua haujlwm zoo li Tebchaws Meskas Mint, uas yuav tsum tsim ntau lab nyiaj npib txhua xyoo.

Txawm hais tias cov txheej txheem nyuaj vim yog automation siv los tsim ntau lab nyiaj npib, muaj ob peb kauj ruam uas txhua mint thoob ntiaj teb siv. Tebchaws Asmeskas Mint yog mint loj tshaj plaws hauv ntiaj teb, thiab peb yuav tsom mus rau nws cov txheej txheem tsim khoom.

1. Cov khoom siv mining

Cov txheej txheem minting pib nrog mining ntawm raw cov ntaub ntawv. Mines los ntawm thoob plaws Tebchaws Meskas thiab thoob ntiaj teb muab kub, nyiaj, tooj liab, lossis lwm yam hlau uas xav tau. Cov hlau nyoos tau los ntawm cov mines no muaj cov impurities uas tsis tsim nyog rau npib.

Ntxiv nrog rau kev khawb ore kom tau txais cov hlau uas xav tau, Tebchaws Asmeskas Mint kuj tseem siv cov hlau rov ua dua tshiab los ntawm ntau qhov chaw. Cov peev txheej no suav nrog cov nyiaj npib uas tsis yog "machinable" thiab raug tshem tawm ntawm kev ncig. Hloov chaw, lawv raug xa rov qab mus rau mint, qhov chaw uas lawv tau rov ua dua tshiab.

2. Refining, Melting, thiab Casting

Cov hlau nyoos yog refined kom tshem tawm yuav luag tag nrho cov impurities. Qee cov nyiaj npib yuav tsum muaj ob lossis ntau hom hlau sib txawv. Cov hlau ua kom zoo yog yaj, thiab cov hlau sib txawv raws li qhov yuav tsum tau ua los ntawm cov lus qhia tshwj xeeb ntxiv. Piv txwv li, Tebchaws Meskas Mint ua nws tsib-xees npib los ntawm 75 feem pua tooj liab thiab 25 feem pua nickel alloy.

Thaum qhov tsim nyog purity los yog alloy tiav lawm, cov hlau yog cam khwb cia rau hauv ib qho ingot. Cov no yog cov hlau loj loj uas muaj cov hlau tsim nyog raws li qhov xav tau los ntawm mint. Cov hlau raug tshuaj xyuas thoob plaws hauv cov txheej txheem kom paub tseeb tias tau txais qhov purity haum.

3. Rolling

Cov txheej txheem ntawm dov lub ingot mus rau qhov tsim nyog thickness yuav ua tau ntev thiab laborious. Lub ingot yog dov ntawm ob hardened steel rollers uas txuas ntxiv mus los ze zog ua ke. Cov txheej txheem no yuav txuas ntxiv mus txog thaum lub ingot yog dov mus rau hauv ib lub hlau sawb uas yog lub thickness tsim nyog rau lub npib ua. Tsis tas li ntawd, cov txheej txheem dov softens cov hlau thiab hloov cov qauv molecular uas tso cai rau nws raug ntaus yooj yim dua thiab tsim cov npib zoo dua.

Thaum nws yog cov khoom siv alloy, nws yuav tsum tau ua annealing ua ntej blanking.

4. Ncua tseg

Tebchaws Asmeskas Mint siv cov yob ntawm cov hlau uas muaj kwv yees li 13 ntiv tes dav thiab hnyav ntau txhiab phaus. Lub yob ntawm cov hlau yog unwound thiab flattened kom tshem tawm cov curvature ntawm cov txheej txheem tsim. Tom qab ntawd nws tau dhau los ntawm lub tshuab uas xuas nrig ntaus tawm ntawm cov hlau uas tam sim no yog qhov tsim nyog tuab thiab txoj kab uas hla rau cov npib ua.

5. Riddle

Txog rau tam sim no, cov txheej txheem tsim khoom siv los tsim cov hlau blanks yog qias neeg thiab khiav hauv ib puag ncig hnyav. Nws yog qhov ua tau rau cov khoom me me ntawm cov hlau khib nyiab kom sib xyaw nrog cov npib blanks. Lub tshuab riddling cais cov blanks kom zoo los ntawm tej yam txawv teb chaws sib xyaw nrog cov npib blanks.

6. Annealing thiab ntxuav

Lub mint ces dhau lub npib blanks los ntawm lub qhov cub annealing kom soften cov hlau nyob rau hauv kev npaj rau striking. Cov blanks ces muab tso rau hauv cov tshuaj da dej kom tshem tawm cov roj thiab cov av uas yuav nyob rau saum npoo ntawm lub npib. Txhua yam khoom txawv teb chaws tuaj yeem nkag mus rau hauv lub npib thaum lub sijhawm tawm tsam, thiab nws yuav tsum tau muab pov tseg.

7. Kev ntxhov siab

Txhawm rau tiv thaiv tus qauv tsim uas yuav txaus siab rau cov hlau npib dawb, txhua lub npib dawb tau dhau los ntawm lub tshuab uas muaj cov txheej txheem ntawm cov menyuam yaus uas tau txais me ntsis me ntsis thiab muab ib qho hlau tsa rau ntawm ob sab ntawm lub npib dawb. Cov txheej txheem no tseem yuav pab xyuas kom meej tias lub npib dawb paug yog txoj kab uas hla yog li nws yuav tawm tsam kom zoo hauv cov xovxwm npib. Tom qab cov txheej txheem no, lub npib dawb yog tam sim no hu ua planchet.

8. Stamping lossis Striking

Tam sim no hais tias cov planchets tau npaj kom zoo, muag muag, thiab ntxuav, tam sim no lawv tau npaj txhij rau kev tawm tsam. Kev lag luam ntaus npib tau cia li pub rau hauv xovxwm npib ntawm tus nqi uas tuaj yeem ncav cuag ntau pua npib ib feeb. Cov ntawv pov thawj ua rau cov neeg sau khoom yog pub los ntawm tes rau hauv cov xovxwm npib thiab tau txais yam tsawg kawg ob zaug ib npib.

9. Kev faib tawm

Cov npib uas dhau kev soj ntsuam tam sim no npaj rau kev faib tawm. Kev lag luam ntaus npib tau ntim rau hauv cov hnab ntim khoom loj thiab xa mus rau cov neeg xa khoom mus rau thoob plaws ntiaj teb. Cov nyiaj npib tau muab tso rau hauv cov neeg tuav tshwj xeeb thiab cov thawv thiab xa mus rau cov neeg sau nyiaj npib thoob ntiaj teb.

Paub meej:

Nyemnruam casting tshuab.

Daim ntawv dov zeb

Muaj ob hom dov mills rau bar / npib ua, thawj hom ntawv dov tshuab ua rau ib txwm nto, qhov no, nws feem ntau xav tau polishing kawg los ntawm tumbler polisher.

| Qauv No. | HS-8HP TSI | HS-10 TSI |

| Hom Lub Npe | HASUNG | |

| Qhov hluav taws xob | 380V 50/60Hz, 3 theem | |

| Hwj chim | 5.5 KW TSI | 7.5 kWm |

| Roller | luas 120 x 210 mm | luas 150 x 220 mm |

| tawv | 60-61 ° | |

| Qhov ntev | 980 × 1180 × 1480mm | 1080x580x1480mm |

| Qhov hnyav | kwv yees. 600 kg | kwv yees. 8 00kg |

| Muaj peev xwm | Qhov siab tshaj plaws Rolling thickness yog li 25 hli | Qhov siab tshaj plaws Rolling thickness yog mus txog 35mm |

| Qhov zoo | Lub thav duab yog electrostatically plua plav, lub cev yog plated nrog cov hniav tawv chrome, thiab stainless hlau npog zoo nkauj thiab siv tau yam tsis muaj xeb. ib leeg-ceev / ob zaug ceev | |

| Tom qab Warranty Service | Video technical support, Kev them nyiaj yug online, Spare qhov chaw, thaj chaw tu thiab kho kev pabcuam | |

Tungsten Steel Daim iav Nto Rolling Mill

Lwm hom yog tungsten steel khoom rau cov menyuam daim iav nto daim ntawv dov zeb. Nrog rau hom dov tshuab, koj yuav tau txais daim iav saum npoo.

| Qauv No. | HS-M5HP | HS-M8HP | ||

| Hom Lub Npe | HASUNG | |||

| Qhov hluav taws xob | 380V; 50/60hz 3 Phase | |||

| Hwj chim | 3.7 kwm | 5.5 kwv | ||

| Tungsten Roller loj | luas 90 x 60 mm | luas 90 x 90 mm | luas 100 x 100 mm | luas 120 x 100 mm |

| Roller Hardness | 92-95 ° | |||

| Khoom siv | imported tungsten steel billet | |||

| Qhov ntev | 880 × 580 × 1400 hli | 980 × 580 × 1450 hli | ||

| Qhov hnyav | kwv yees. 450kg ua | kwv yees. 500 kg | ||

| Nta | Nrog lubrication; iav tsav; Rolling sheet thickness 10mm, thinnest 0.1 hli; extruded ntawv hlau nto iav nyhuv; static hmoov txau rau ntawm tus ncej, hniav hard chrome plating, stainless hlau npog, zoo nkauj thiab tswv yim yuav tsis rusty. | |||

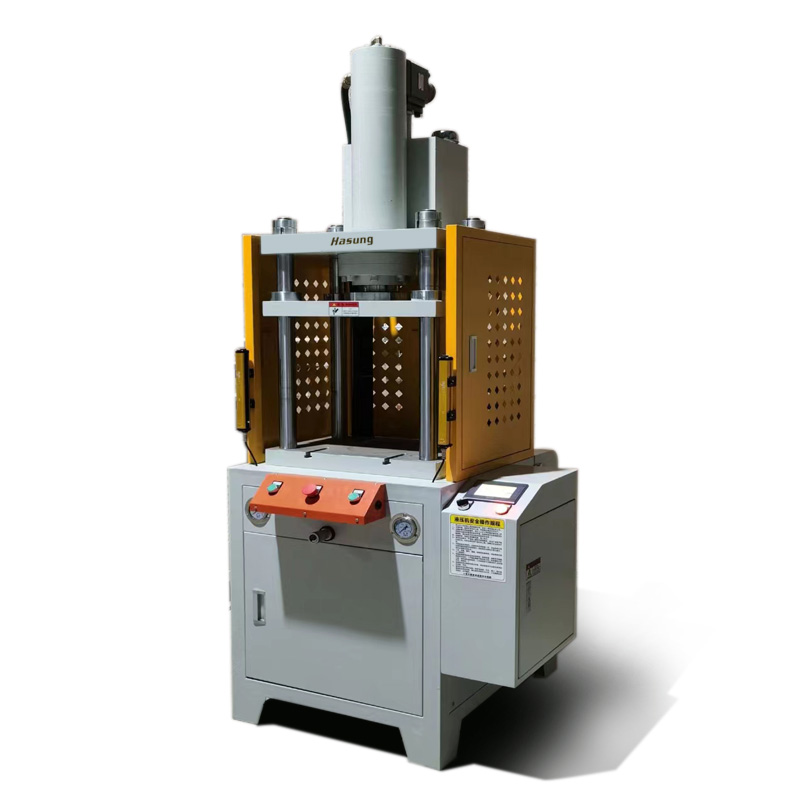

HYDRAULIC Npib BLANKING Xovxwm

Txoj Kev Blanking

20 Tuj Hydraulic Npib Txiav / Blanking Xovxwm

40 Tuj Hydraulic Txiav & Embossing Xovxwm

Cov hydraulic txiav xovxwm txiav cov kub thiab nyiaj blanks ntawv uas yog ua tiav tom qab dov. Daim ntawv dawb yog txiav tawm mus rau qhov xav tau zoo li lub voj voog, duab plaub, pendant zoo li tus thiab lwm yam. Muab los ntawm kev txiav cov txheej txheem tom qab uas cov blanks npaj tau minted rau hauv hydraulic stamping xovxwm.

Qhov zoo ntawm hydraulic txiav fais fab xovxwm tshuab.

Zoo tagnrho rau kub thiab nyiaj blanks txiav,

Txiav cov blanks hauv cov npoo kom zoo dua,

Hassle free kev khiav hauj lwm thiab dual hom kev khiav hauj lwm nrog ko taw thiab hloov,

Stopper system rau kev txiav txuas ntxiv,

Tuag haum kho qhov system nrog yooj yim deposit tub rau khoom,

Txiav kev hloov kho kom nrawm dua.

Nruab nrog lub blanking trough device, nws yooj yim los sau cov ntaub ntawv.

Technical Parameters

| Qauv No. | HS-20 T | HS-40 T | HS-100 T |

| Nominal | 20 ton | 40 ton | 100 ton |

| Max stroke | 300 hli | 350 hli | 400 hli |

| Qhib qhov siab | 500 hli | 400 hli | 600 hli |

| nqis ceev | 160 hli | 180 hli | 120 hli |

| Kev nce ceev | 150 hli | 160 hli | 120 hli |

| Chaw ua haujlwm rooj | 600 * 500 hli | 550 * 450 hli | 700 * 600 hli |

| Rooj qhov siab ntawm av | 8 50mm | 8 50mm | 8 50mm |

| Qhov hluav taws xob | 380V 3 theem | 380V 3 theem | 380V 3 theem |

| Lub cev muaj zog | 3.75 kwm | 3.75 kwm | 5.5 kwv |

| Qhov hnyav | 1300 KG | 8 60 KG | 2200 KG |

100 TujHydraulic npib Embossing Xovxwm

150 Tuj Hydraulic Npib Embossing Xovxwm

200 Tuj Hydraulic Npib Embossing Xovxwm

300 Tuj Hydraulic Kub thiab Nyiaj Npib Xovxwm

150 tons hydraulic npib embossing xovxwm haum rau ua npib mus txog 50 grams nyiaj. Cov xovxwm yog tsim rau kev khiav hauj lwm hauv phau ntawv raws li ib lub voj voog tsis siv neeg ua haujlwm hom. Nws muaj nrog nws pib npib ejecting mechanism. Cov xovxwm tuaj yeem muab tau rau hauv ntau lub peev xwm xws li 80 tons, 100 tons, 150 tons, 200 tons raws li koj xav tau.

300 tons muaj peev xwm hydraulic npib xovxwm tshuab rau kub thiab nyiaj ua tiav nrog programmable PLC maub los rau ntau yam strokes ntawm theem kawg. Cov xovxwm yog nruab nrog ejector lub tog raj kheej rau nws pib ejection ntawm npib kom yooj yim tshem tawm yam tsis muaj hammering. Qhov no feature muab qhov zoo kawg nkaus tiav ntawm npib. Qhov no hydraulic coining xovxwm yog tsim rau ua kub thiab nyiaj npib los ntawm 1.0 gram mus rau 100.0 grams nyob rau hauv qhov hnyav thiab yog powered los ntawm 10.0 HP (7.5KW) hluav taws xob thiab yog muab los ntawm cov khoom siv hluav taws xob tsim nyog thiab tswj vaj huam sib luag. Qhov kev tsim npib npib no suav nrog kev hloov kho siab nrog lub sijhawm los kho lub sijhawm kawg siab ua ntej rov qab mob stroke. Nws tuaj yeem ua haujlwm los ntawm kev tswj lub laub khawm nrog rau hauv hom tsis siv neeg ib zaug.

Dhau li ntawm hydraulic coining xovxwm thiab precision sheet dov zeb, koj xav tau induction melter los yog nruam casting tshuab rau kub thiab nyiaj daim ntawv ua, kub thiab nyiaj bar txiav tshuab thiab vibrator polisher tshuab yuav tsum tau teem kom tiav kub thiab nyiaj npib ua cog.

Technical Parameters

| Qauv No | HS-100 T | HS-200 T | HS-300 T |

| Qhov hluav taws xob | 380V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

| Hwj chim | 4 KW | 5.5 KW TSI | 7.5 kWm |

| Max. siab | 22 Mpa | 22 Mpa | 24 Mpa |

| Lub rooj ua haujlwm stroke | 110 hli | 150 hli | 150 hli |

| Max. qhib | 360 hli | 380 hli | 380 hli |

| Lub rooj ua haujlwm nce nrawm nrawm | 120mm / s | 110mm / s | 110mm / s |

| Lub rooj ua haujlwm rov qab nrawm | 110mm / s | 100mm / s | 100mm / s |

| Ua hauj lwm rooj loj | 420 * 420 hli | 500 * 520 hli | 540 * 580 hli |

| Qhov hnyav | 1100 kg | 2400kg ib | 3 300kg |

| Daim ntawv thov | rau cov hniav nyiaj hniav kub thiab kub bar, npib logo stamping | ||

| Feature | Ib txwm / Servo lub cev muaj zog rau kev xaiv, khawm ua haujlwm / Simens PLC Tswj System rau kev xaiv | ||

Puv Tsis Siv Neeg Npib Ua Ntau Lawm System

Koj tuaj yeem tso nyiaj nrog Hasung muab koj ib qho kev daws teeb meem rau cov nyiaj npib minting kab. Cov pob khoom tsim muaj xws li kev taw qhia ntawm qhov chaw, cov khoom siv minting npib, thiab cov kws tsim khoom los pab koj ntsuas cov txheej txheem. Peb cov engineers tau koom nrog hauv cov txheej txheem kub ua cov kev tshawb fawb thiab tau ua tus kws pab tswv yim rau cov mint paub zoo.

Hasung tsom ntsoov rau kev daws cov teeb meem minting npib thaum muab cov lus qhia ua ntu zus ntawm cov hlau muaj txiaj ntsig. Rau 20+ xyoo peb tau nyob rau hauv lub forefront ntawm kub thiab nyiaj npib ua tshuab, peb muaj kev cob qha engineering kev pab cuam, nyob rau hauv lub site kev cob qhia, thiab technical support Peb Cov Kev Pabcuam.

Lub sij hawm xa tuaj: Plaub Hlis-04-2022