Cov khoom

-

Nruam Casting Tshuab rau kub Silver Copper Alloy 20kg 30kg 50kg 100kg

1.As sai li sai tau nyiaj kub sawb hlau raj pas nrignruam casting tshuabrau cov hniav nyiaj hniav kub tau nthuav tawm ntawm kev ua lag luam, nws tau txais cov lus pom zoo los ntawm ntau tus neeg siv khoom, uas tau hais tias cov khoom siv no tuaj yeem daws lawv cov kev xav tau zoo. Ntxiv mus, cov khoom siv dav siv hauv Hlau Casting.

2.Nruam Casting Tshuab rau Ua Qws Sawb Yeeb Nkab nrog 20kg 30kg 50kg 100kg piv nrog cov khoom zoo sib xws ntawm kev ua lag luam, nws muaj qhov zoo sib xws ntawm kev ua tau zoo, zoo, tsos, thiab lwm yam, thiab nyiam lub koob npe nrov hauv khw.Hasung qhia txog qhov tsis xws luag ntawm cov khoom yav dhau los, thiab txuas ntxiv txhim kho lawv. Cov specifications ntawm Nruam Casting Tshuab rau Ua Qws Sawb Yeeb Nkab nrog 20kg 30kg 50kg 100kg tuaj yeem kho raws li koj xav tau.

-

Hlau Flakes Ua Tshuab Kub Flakes Ua Khoom Siv Rau Kub Refining

Khoom Taw qhia:

1. Txais qhov nruab nrab zaus induction, lub sijhawm luv melting thiab kev ua haujlwm siab.

2. Lub melting chamber siv cov roj inert uas yog siv los tiv thaiv oxidation ntawm cov ntaub ntawv hlau thiab kev koom ua ke ntawm impurities. Rau lub hom phiaj no, nws yog tsim rau high-purity hlau cov ntaub ntawv los yog smelting uas yooj yim oxidized ntsiab.

3. Cov neeg kho tshuab stirring muaj nuj nqi nyob rau hauv lub nqus tsev vacuum yog saws, thiab cov xim tsim tsis segregated.

4. Lub smelting yog tiv thaiv los ntawm high-purity inert gas, yog li cov graphite ruthenium muaj oxidation tsawg heev.

5. Siv Taiwan Weinview / Siemens PLC maub los, kev ua haujlwm yooj yim.

6. Cov pwm yog cia li rhuab thaum lub sij hawm pouring txheej txheem los xyuas kom meej qhov zoo ntawm cov casting.

7. Nrog ntau lub ntiaj teb nto moo hom khoom kom paub meej zoo.8. Feem ntau yog siv rau kev kho kub.

-

Rotary Nqus Induction Melting Rauv (VIM) FIM / FPt (Platinum, Palladium Rhodium thiab Alloys)

FIM / FPt yog lub tshuab nqus tsev rau melting platinum, palladium, rhodium, hlau, thiab kub alloys nrog tilting mechanism.

Nws tuaj yeem siv tau kom tau txais lub zoo meej melting ntawm platinum thiab palladium alloys yam tsis muaj cov pa roj.

Nws tuaj yeem yaj los ntawm qhov tsawg kawg nkaus ntawm 500g mus rau qhov siab tshaj ntawm 10kg ntawm Platinum hauv feeb.

Lub melting unit yog tsim los ntawm cov dej-txias stainless hlau casing nyob rau hauv uas rooj plaub nrog crucible tig thiab ib tug ingot pwm rau tilting casting.

Lub melting, homogenization thiab casting theem tuaj yeem tshwm sim hauv lub tshuab nqus tsev lossis hauv qhov chaw tiv thaiv.

Lub cub tawg ua tiav nrog:

- Ob chav theem rotary vane lub tshuab nqus tsev twj tso kua mis hauv roj da dej;

- High precision digital siab sensor;

- Optical pyrometer rau kev tswj qhov kub thiab txias;

- High precision digital lub tshuab nqus tsev hloov rau lub tshuab nqus tsev nyeem ntawv + Zaub.

Qhov zoo

- Lub tshuab nqus tsev melting technology

- Manual/Automatic tilting system

- Kub melting kub

Hasung TechnologyHigh Temperature Nqus Tsev Induction Melting Rauv Kev Ntsuas Lub Nqus Melting Rauv

Khoom nta

1. Ceev ceev melting, qhov kub tuaj yeem ncav cuag 2200 ℃

2. Nrog rau txhua yam stirring muaj nuj nqi, cov khoom yog stirred ntau tusyees

3. Nruab nrog programmed kub tswj, teem lub cua sov los yog txias nkhaus raws li koj cov txheej txheem yuav tsum tau, cov khoom yuav cia li cua sov los yog txias raws li cov txheej txheem no.

4. Nrog rau cov khoom siv pouring, cov qauv molten tuaj yeem nchuav rau hauv cov pwm npaj, thiab cov duab ntawm cov qauv koj xav tau tuaj yeem nchuav.

5. Nws tuaj yeem smelted nyob rau hauv ntau yam huab cua: smelting hauv huab cua, tiv thaiv huab cua thiab lub tshuab nqus tsev siab, yuav ib yam khoom siv, paub txog ntau yam haujlwm; txuag koj cov nqi rau ib qho twg.

6. Nrog rau kev noj zaub mov thib ob: Nws tuaj yeem paub ntxiv lwm cov ntsiab lus thaum lub sij hawm melting txheej txheem, uas yooj yim rau koj los npaj ntau yam qauv.

7. Lub qhov cub lub cev yog tag nrho cov hlau stainless nrog cov dej txias kom ntseeg tau tias qhov kub ntawm lub plhaub yog qis dua 35 ° C los tiv thaiv koj tus kheej kev nyab xeeb.

-

Tilting induction melting tshuab rau kub Silver Copper 2kg 3kg 4kg 5kg 6kg

Tus tsim ntawm no tilting melting system yog raws li qhov xav tau tiag tiag ntawm qhov project thiab txheej txheem, siv cov cuab yeej siv niaj hnub high-tech. Kev nyab xeeb lav.

1. Txais lub teb chaws Yelemees IGBT cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv tshuab, uas tuaj yeem yaj hlau hauv lub sijhawm luv luv, txuag lub zog thiab ua haujlwm zoo.

2. Siv electromagnetic stirring muaj nuj nqi, tsis muaj segregation nyob rau hauv cov xim.

3. Nws txais qhov yuam kev pov thawj (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim rau kev siv.

4. Siv PID kub tswj qhov system, qhov kub yog qhov tseeb dua (± 1 ° C) (yeem).

5. Cov khoom siv HS-TFQ smelting yog tus kheej tsim thiab tsim nrog cov khoom siv qib siab tshaj plaws rau kev smelting thiab casting kub, nyiaj, tooj liab, thiab lwm yam.

HS-TFQ series yog tsim los rau melting platinum, palladium, Rhodium, kub, nyiaj, tooj liab thiab lwm yam alloys.

6. Cov khoom siv no siv ntau yam khoom lag luam nto moo txawv teb chaws.

7. Nws ua kom cua sov thaum nchuav cov kua hlau ntawm ib qho kev mob zoo uas ua rau cov neeg siv tau zoo casting zoo.

-

Smelt Cub Induction Speedy Melting 20kg 30kg 50kg 100kg Los Ntawm Txhais Tes Tilting Kub Smelting Rauv

Tilting Melting Rauv rau melting ntau ntau ntawm hlau rau hauv ingots los yog bullions.

Cov cav tov no yog tsim los rau melting ntau ntau, piv txwv li nyob rau hauv lub kub recycle Hoobkas rau loj muaj peev xwm melting ntawm 50kg los yog 100kg ib batch.

Hasung TF series - sim thiab sim nyob rau hauv foundries thiab precious hlau refining pawg.Peb tilting smelting furnaces yog siv nyob rau hauv ob qhov chaw:

1. rau melting ntau ntau ntawm hlau xws li kub, nyiaj los yog manufacturing hlau kev lag luam xws li casting scraps, 15KW, 30KW, thiab siab tshaj plaws 60KW tso zis thiab tsawg zaus tuning txhais tau tias ceev melting uas nyiam qhov zoo tshaj plaws tau los ntawm Tuam Tshoj - txawm rau loj ntim. - thiab zoo heev los ntawm kev sib xyaw.

2. rau casting loj, hnyav Cheebtsam tom qab casting nyob rau hauv lwm yam lag luam.

Lub compact thiab muaj txiaj ntsig zoo tilting furnaces los ntawm TF1 mus rau TF15 yog siv nyob rau hauv kev lag luam jewellery thiab nyob rau hauv precious hlau foundries, yog kiag li tshiab tsim. Lawv tau nruab nrog kev ua haujlwm siab tshiab induction generators uas ncav cuag lub melting point sai sai thiab xyuas kom meej sib tov thiab homogenisation ntawm cov hlau molten. Lub TF20 rau TF100 qauv, Nyob ntawm tus qauv, lub peev xwm ntawm ib tug crucible ntim ntawm 20kg mus rau 100kg rau kub, feem ntau rau precious hlau manufacturing tuam txhab uas muag.

TFQ series tilting furnaces yog tsim los rau ob qho tib si platinum thiab kub, tag nrho cov hlau xws li platinum, palladium, stainless hlau, kub, nyiaj, tooj liab, alloys thiab lwm yam, yuav yaj nyob rau hauv ib lub tshuab los ntawm kev hloov crucibles xwb.

Hom furnaces no zoo heev rau platinum melting, yog li thaum pouring, tshuab ua kom cua sov kom txog thaum koj yuav luag tas, ces ncuav shuts cia thaum yuav luag tiav.

-

Induction Melting Rauv rau Kub Platinum Silver Copper Rhodium Palladium

MU melting unit system yog raws li qhov xav tau tiag tiag ntawm cov hniav nyiaj hniav kub melting thiab cov hlau muaj txiaj ntsig ua kom zoo nkauj lub hom phiaj.

1. HS-MU melting units yog tus kheej tsim thiab tsim nrog cov khoom siv qib siab tshaj plaws rau cov smelting thiab casting kub, nyiaj, tooj liab thiab lwm yam alloys.

2. HS-MUQ melting furnaces yog nruab nrog ib lub tshuab hluav taws xob cua sov tab sis dual siv rau smelting thiab casting ntawm platinum, palladium, stainless hlau, kub, nyiaj, tooj liab thiab lwm yam alloys, uas yuav siv tau los ntawm kev hloov crucibles xwb. Yooj yim thiab yooj yim.

-

1kg 2kg Mini Induction Melting Rauv rau Kub Silver Copper

Lub desktop mini induction melting rauv, muaj peev xwm ntawm 1kg-2kg, uas yuav siv sij hawm 1-2 feeb kom yaj ib batch ntawm hlau. Nws los nyob rau hauv ib tug compact tsim thiab yuav ua tau 24 teev tsis tu ncua ua hauj lwm. Tsis tas li ntawd, lub qhov cub hlau no yog ib puag ncig zoo heev, siv 6KW lub zog nrog 220V ib theem uas txuag tau ntau lub zog kom xa cov txiaj ntsig xav tau.

Nws tau pom zoo heev rau cov khoom lag luam me me los yog cov hniav nyiaj hniav kub rhiav, siv tau zoo thiab siv lub neej ntev. Txawm hais tias nws yog cov cuab yeej me me, nws ua tiav txoj haujlwm zoo rau cov neeg siv.

Kev tswj qhov kub thiab txias yog xaiv tau rau lub tshuab no.

-

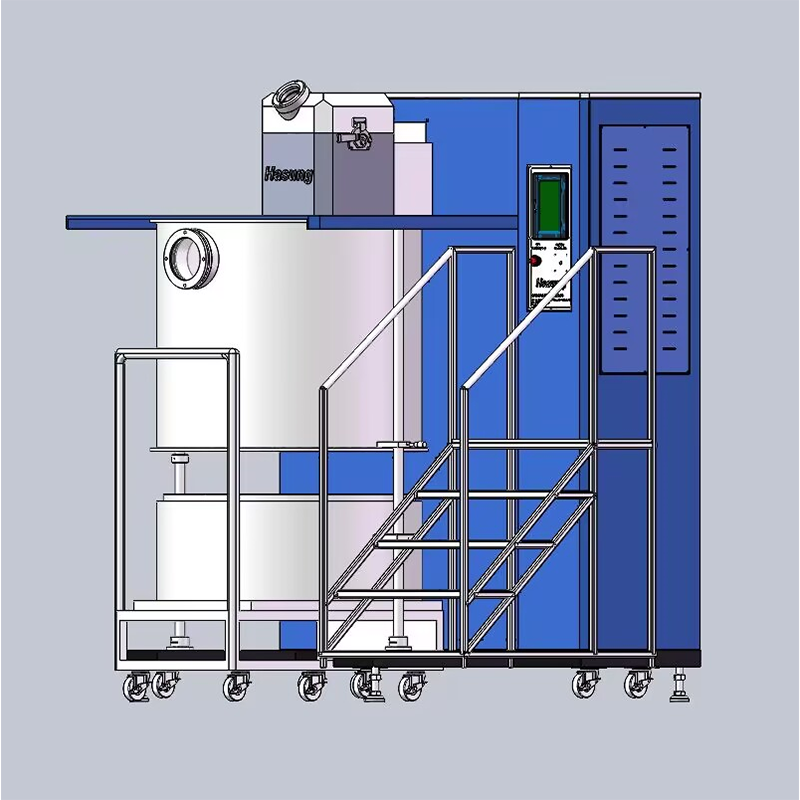

Tsis Siv Neeg Kub Nyiaj Bullion Nqus Casting Tshuab 2KG

Vim Li Cas Koj Xaiv Hasunglub tshuab nqus tsevKub Bar Casting Tshuab?

Hasung Nqus Ingot Casting tshuab (HS-GV2) yog tsim los rau casting 2kg zoo nyiaj thiab kub bullions. Lub tshuab casting no los nrog qhov yooj yim ntawm cov pwm los kho koj cov nyiaj thiab kub tuav, ingots thiab bullions nrog ib qho ntawm koj tus qauv tsim thiab ntau thiab tsawg.

Lub inert gas chamber ntawm no kub nyiaj bar casting tshuab xyuas kom meej tias koj muaj ib tug zaum kawg casting nrog hwm zoo thiab daim iav zoo li los ntawm tag nrho cov ntaub ntawv ntawm porosity, dej nthwv dej los yog shrinkage nyob rau hauv koj zaum kawg daim.

Muab piv nrog cov txheej txheem ib txwm muaj. Koj tag nrho cov txheej txheem casting yuav ua tiav nyob rau hauv lub tshuab nqus tsev thiab inert gas. Li no muab koj cov khoom siv casting zoo. Nrog rau cov yam ntxwv saum toj no koj cov neeg ua haujlwm tau lees paub tag nrho los ua haujlwm peb cov khoom siv tau yooj yim.

Hasung cov khoom qub yog los ntawm cov neeg paub zoo hauv tsev thiab lub ntiaj teb nto moo hom xws li Nyiv AirTec, Taiwan Weinview, thiab German Siemens, Schneider, Omron, thiab lwm yam.

-

Tsis Siv Neeg Kub Bullion Nqus Casting Tshuab 12KG 15KG 30KG

Vim Li Cas Koj Xaiv HasungLub tshuab nqus tsevKub Bar Casting Tshuab?

Hasung Nqus Bullion Casting Tshuab piv rau lwm lub tuam txhab

1. Nws yog qhov sib txawv loj. lwm lub tuam txhab nqus tsev yog tswj los ntawm lub sijhawm. Lawv tsis yog lub tshuab nqus tsev tiag tiag. Lawv cia li tso nws lub cim. Thaum lawv nres twj, nws tsis yog lub tshuab nqus tsev, yooj yim xau tawm. Peb cov twj tso kua mis mus rau qhov chaw nqus tsev vacuum thiab tuaj yeem tswj lub tshuab nqus tsev mus ntev.

2. Hauv lwm lo lus, yam lawv muaj yog lub tshuab nqus tsev lub sijhawm.

Piv txwv li, ntxiv roj inert tom qab ib feeb lossis 30 vib nas this yog tsis siv neeg. Yog tias nws tsis ncav cuag lub tshuab nqus tsev, nws yuav hloov mus rau inert gas. Nws yog qhov tseeb, cov roj inert thiab huab cua tau noj tib lub sijhawm. Nws tsis yog lub tshuab nqus tsev kiag li. Lub tshuab nqus tsev tsis tuaj yeem khaws cia rau 5 feeb. Hasung tuaj yeem tuav lub tshuab nqus tsev rau ntau tshaj nees nkaum teev.

3. Peb tsis zoo ib yam. Peb tau kos lub tshuab nqus tsev. Yog tias koj nres lub tshuab nqus tsev twj, nws tseem tuaj yeem tuav lub tshuab nqus tsev. Rau ib lub sij hawm ntawm lub sij hawm, peb yuav ncav cuag lub teeb Tom qab teeb tsa tus nqi, nws tuaj yeem hloov mus rau kauj ruam tom ntej thiab ntxiv roj inert.

4. Hasung cov khoom qub yog cov npe nrov ntawm Nyiv, Fabkis thiab lub teb chaws Yelemees.

-

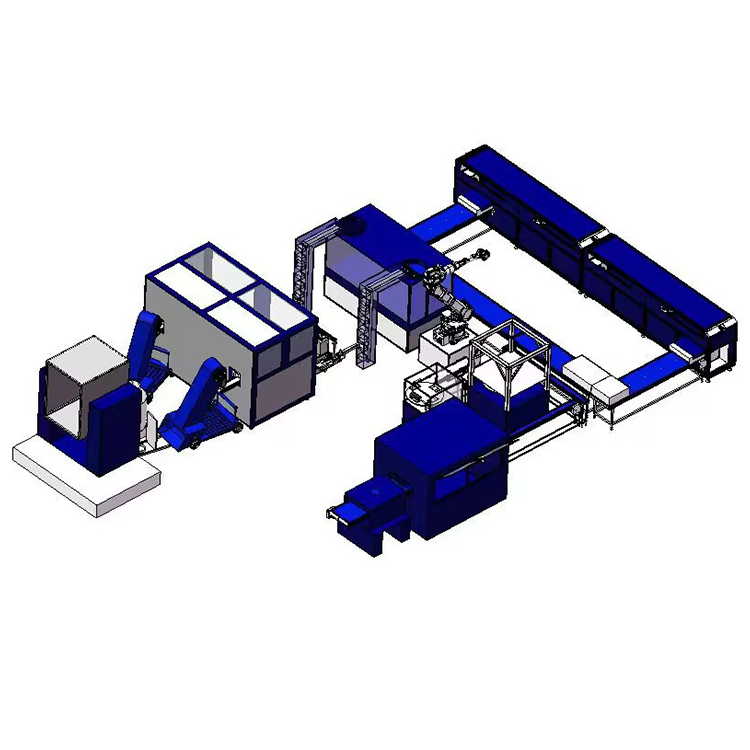

Qhov Hom Kub Ingot Nqus Casting System

HS-VF260 yog lub qhov cub induction uas, txawm hais tias nws koom nrog kev siv tshuab siab heev, hloov tau yooj yim thiab siv tau yooj yim. Muaj nyob rau hauv cov qauv sib txawv, txhua Tera Automation HS-VF260 yog tsim, tswj thiab sib sau ua ke hauv peb lub tuam txhab.

Peb lub qhov cub tawg tau muab faib ua peb chav, qhov twg cov nplej tau yaj hauv qhov chaw tswj tau thiab raug muab pov rau hauv glossy thiab tiaj tus kub lossis nyiaj ingots. Cov patented thev naus laus zis hu ua Pinch Valves, muab tso rau ntawm ob qhov kawg ntawm lub qhov, ua kom muaj kev sib khi zoo meej: raws li qhov tseeb, qhov system no nrog pneumatic li qub khaws cov pa tawm sab nraum lub qhov, tswj qhov cua tsis zoo thiab txo qis roj - feem ntau nitrogen - noj. . Graphite consumables kav ntev dua thiab tsis deteriorate vim oxidation.

Zoo li tag nrho lwm yam induction casting furnaces, lub cub tawg no yuav tsum tau txuas nrog lub tshuab tso dej tub yees kom zoo.

-

TVC Series Induction Nqus Plua Plav Casting Tshuab rau Kub Silver Copper

Puv Tsis Siv Neeg Lub Tshuab Nqus Siab Casting Tshuab

Cov cuab yeej tshiab los txhim kho cov txiaj ntsig casting

Hasung Casting System

1. Kaw lub hau yuav, txhua yam yog automaticlly kev khiav hauj lwm rau casting feem ntau txhim kho cov khoom ntws thiab pwm filling

2.Castings nthuav tawm ntau dua thiab zoo ib yam

3.Porosity tau txo qis

4. Nrog Max. 4 bars casting siab.

5. SBS txiav tshuab tsis siv cov gaskets, txuag nqi.

6.Castings muaj kev ntxhov siab ntau dua thiab elasticity, ua rau lawv yooj yim dua rau kev ua haujlwm ntxiv.

7. Ib qho yooj yim kov ua haujlwm nrog cov txiaj ntsig parameter screen

8. 100 cov kev pab cuam muaj.

-

VPC Series Nqus Siab Casting Tshuab rau Jewellery

Siab tshaj lub tshuab nqus tsev Casting

VCT yog ib tsev neeg ntawm siab tshaj lub tshuab nqus tsev casting tshuab tsim los ua kom tau raws li qhov xav tau hnyav dua hauv kev ploj tuag casting ntau lawm ntawm kub, K-kub, tooj liab, bronze, alloys. Lawv feem ntau siv nyob rau hauv kev twb kev txuas mus rau ib tug 3d tshuab luam ntawv rau ncaj qha casting kom tau cov thawj hlau qhov chaw ntawm complex khoom.

Cov tsev neeg ntawm cov tshuab no ua haujlwm nrog lub tswv yim tshiab, hloov pauv ob chav chamber. Qhov kev tsim kho tshiab no muab ntau qhov zoo dua piv nrog cov tsoos ib leeg chamber suction system tam sim no muaj nyob hauv khw.

Nyob rau hauv VCT, melting chamber thiab flask chamber yog tag nrho indipendent: thaum casting, lub tshuab tuaj yeem tswj cov hlau txhaj rau hauv pwm los ntawm kev siv lub siab sib txawv thaum lub sij hawm nchuav. Qhov no yields rau kev txhaj tshuaj sai dua piv rau qhov yooj yim lub ntiajteb txawj nqus pouring nrog cov txiaj ntsig los nrum cov khoom ntawm qhov kub thiab txias. Qhov no yuav ua rau kom zoo dua nto tiav thiab txo qis shrinkage ntawm cov khoom cam khwb cia.Lub voj voog casting tsuas siv ob peb feeb xwb thiab, thaum lub khob dej dhau los txias hauv cov roj tiv thaiv kom tsis muaj oxidation, tus nqi tom ntej tuaj yeem thauj mus rau hauv crucible thiab melted, yog li sib tshooj ob lub voj voog tsis muaj sij hawm pov tseg.

Lub tshuab yog siab tsis siv neeg, featuring PC raws li kev saib xyuas cov txheej txheem tsis tau txais thiab kev tswj cov ntaub ntawv ntau lawm, nrog kev kho kom yooj yim ntawm cov kev pab cuam casting tsim rau ntau hom hlau.

Lub tshuab revolutionary no yog cov synthesis ntawm feem ntau advanced engineering thiab xyoo ntawm kev paub nyob rau hauv casting uas tsuas Hasung yuav coj nyob rau hauv koj lub Hoobkas.