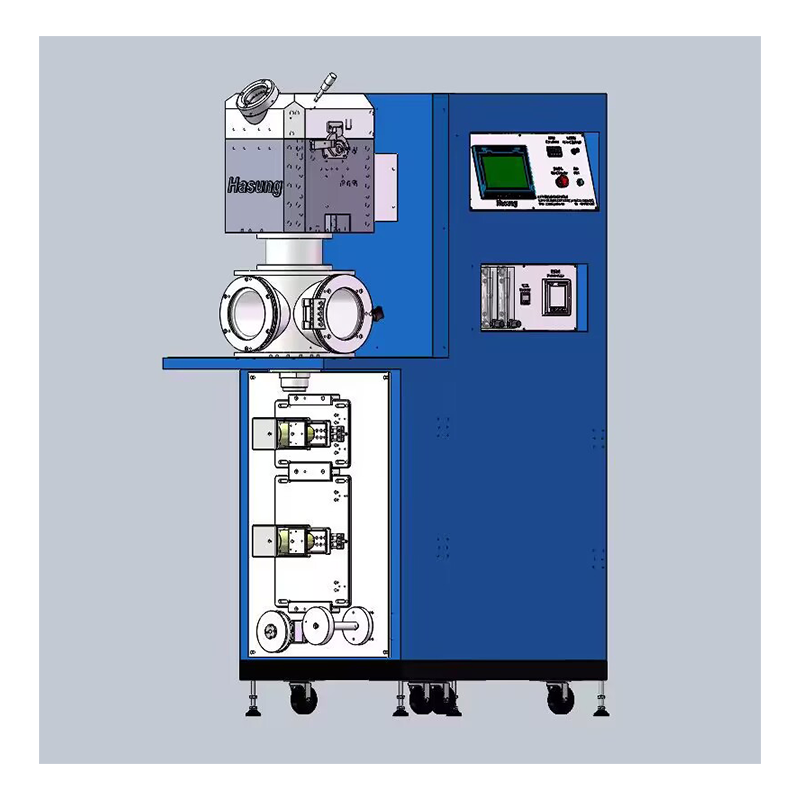

Precious Hlau Kab rov tav Vacuum Nruam Casting Tshuab

Technical Parameters

| Qauv No. | HS-VHCC 20 | HS-VHCC 30 | HS-VHCC 50 | HS-VHCC 100 |

| Qhov hluav taws xob | 380V, 50/60Hz, 3P | |||

| Hwj chim | 25 KW | 30 KW | 35 KW TSI | 50 kWm |

| Max. Temp. | 1600 ° C | |||

| Casting Ceev | 400mm-1000mm / min.(tuaj yeem teeb tsa) | |||

| Temp. Qhov tseeb | ± 1℃ | |||

| Nqus casting | Xaiv tau | |||

| Casting hlau | Kub, nyiaj, tooj dag, bronze, tooj liab, alloys | |||

| Inert gas | Argon / Nitrogen | |||

| Tswj qhov system | Taiwan Weinview / Siemens PLC kov npo | |||

| Txoj kev ua kom txias | Dej txias system (muag nyias) | |||

| Hlau / ntawv winder | Kev muab khoom los ntawm tus neeg siv lossis xaiv tau rau kev muab khoom | |||

| Dimension | kwv yees. 2500 * 1120 * 1550mm | |||

| Qhov hnyav | kwv yees. 11 80kg | |||

Khoom Qhia

Qhov Zoo & Nta

Kab rov tav nqus nruam caster: qhov zoo thiab nta

Kab rov tav lub tshuab nqus tsev nruam casters yog ib feem tseem ceeb ntawm kev lag luam hlau casting thiab muab ntau yam txiaj ntsig thiab cov yam ntxwv uas ua rau lawv muaj kev xaiv nrov ntawm cov tuam ntxhab. Cov tshuab no yog tsim los tsim cov khoom zoo hlau nrog precision thiab efficiency. Nyob rau hauv tsab xov xwm no, peb yuav tshawb txog qhov zoo thiab cov yam ntxwv ntawm kab rov tav lub tshuab nqus tsev casters thiab lawv qhov cuam tshuam rau cov txheej txheem hlau casting.

Qhov zoo ntawm kab rov tav lub tshuab nqus tsev nruam casting tshuab

1. Txhim kho cov khoom zoo: Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kab rov tav lub tshuab nqus tsev nruam casting yog lub peev xwm los tsim cov khoom siv hlau zoo. Lub tshuab nqus tsev ib puag ncig pab txo qis impurities thiab roj nkag mus rau hauv cov hlau molten, ua rau cov khoom sib xws thiab ua kom zoo dua. Qhov no txhim kho cov khoom siv kho tshuab thiab qhov chaw tiav ntawm cov hlau cam khwb cia, ua rau nws haum rau ntau yam kev siv.

2. Txhim kho cov txheej txheem tswj: kab rov tav lub tshuab nqus tsev nruam casting tuaj yeem tswj cov txheej txheem casting. Kev siv lub tshuab nqus tsev tso cai rau kev tswj xyuas kom zoo dua ntawm cov cua txias thiab solidification ntawm cov hlau, uas ua rau muaj kev sib raug zoo thiab tswj cov txheej txheem casting. Cov txheej txheem kev tswj hwm qib no pab txo qis qhov tsis xws luag thiab ua kom cov khoom zoo ntawm cov castings zoo.

3. Kev Tsim Nyog Muaj Peev Xwm: Cov tshuab no tau tsim los ua haujlwm tas mus li kom ua tiav cov khoom lag luam siab. Kab rov tav orientation ntawm cov txheej txheem casting tso cai rau kev tsim cov castings ntev, txo qhov kev xav tau ntawm cov pwm hloov ntau zaus thiab ua kom tag nrho cov khoom tsim tau. Qhov no ua rau kab rov tav lub tshuab nqus tsev casters ib qho kev daws teeb meem zoo rau cov tuam txhab nrhiav kom zoo dua lawv cov txheej txheem ntau lawm.

4. Kev siv hluav taws xob: Kab rov tav nruam casting tshuab siv lub tshuab nqus tsev kom txo tau lub zog noj thaum lub sij hawm casting txheej txheem. Los ntawm kev tsim kom muaj kev tswj hwm ib puag ncig, qhov kev xav tau ntawm cov khoom siv hluav taws xob ntau dhau yog txo qis, txuag hluav taws xob thiab txo cov nqi khiav lag luam rau cov tuam txhab.

Cov yam ntxwv ntawm kab rov tav lub tshuab nqus tsev nruam casting tshuab

1. Kab rov tav Casting Design: Kab rov tav orientation ntawm cov tshuab no tso cai rau kev nruam nruam ntawm cov khoom siv hlau ntev thiab zoo ib yam. Cov qauv tsim no tshwj xeeb tshaj yog muaj txiaj ntsig zoo rau kev tsim cov pas nrig, cov raj thiab lwm yam khoom siv ntev ntev, ua rau nws muaj ntau yam kev daws teeb meem rau ntau yam kev siv hlau casting.

2. Nqus Chamber: Lub tshuab nqus tsev chamber nyob rau hauv kab rov tav nruam caster plays lub luag haujlwm tseem ceeb hauv kev tsim kom muaj kev tswj hwm ib puag ncig rau txheej txheem casting. Lub tshuab nqus tsev pab txhim kho qhov zoo thiab kev ncaj ncees ntawm cov khoom cam khwb cia los ntawm kev tshem tawm cua thiab lwm yam impurities los ntawm cov hlau molten.

3. Cov tshuab cua txias: Cov tshuab no tau nruab nrog cov tshuab txias txias uas tuaj yeem tswj tau cov txheej txheem solidification. Tus nqi cua txias yog adjustable kom tau raws li cov kev cai tshwj xeeb ntawm cov hlau alloys sib txawv, kom ntseeg tau tias cov khoom zoo castings nrog cov khoom zoo ib yam.

4. Automation thiab tswj qhov system: Kab rov tav lub tshuab nqus tsev nruam casting yog nruab nrog kev ua haujlwm siab thiab kev tswj hwm, uas tuaj yeem saib xyuas thiab kho cov txheej txheem casting. Qib no ntawm automation pab txo tib neeg kev ua yuam kev thiab ua kom muaj kev rov ua dua ntawm cov khoom tsis zoo, ua rau cov khoom zoo ib yam.

Hauv cov ntsiab lus, kab rov tav lub tshuab nqus tsev casters muaj ntau qhov zoo thiab cov yam ntxwv uas ua rau lawv xaiv thawj zaug rau kev siv hlau casting. Los ntawm kev txhim kho cov khoom zoo thiab cov txheej txheem tswj kom txhim kho cov khoom tsim tau thiab lub zog ua haujlwm, cov tshuab no ua lub luag haujlwm tseem ceeb hauv kev tsim cov khoom hlau zoo. Nrog rau kev tsim thiab thev naus laus zis, kab rov tav lub tshuab nqus tsev txuas txuas txuas ntxiv tsav kev tsim kho tshiab thiab kev ua haujlwm zoo hauv kev lag luam hlau casting.

Vim li cas thiaj xaiv peb: Taw qhia rau Kab rov tav Nqus Nruam Casting Tshuab

Hauv kev lag luam hlau casting, kab rov tav lub tshuab nqus tsev nruam casting yog cov cuab yeej tseem ceeb thiab ua lub luag haujlwm tseem ceeb hauv kev tsim cov khoom siv hlau zoo. Lub tshuab thev naus laus zis no hloov pauv cov txheej txheem casting thiab muaj ntau yam zoo dua li cov txheej txheem ib txwm muaj. Hauv tsab xov xwm no, peb yuav ua tib zoo saib ntawm kab rov tav lub tshuab nqus tsev casters thiab tshawb nrhiav vim li cas xaiv peb rau koj qhov kev xav tau casting yog qhov kev txiav txim siab zoo tshaj plaws uas koj tuaj yeem ua.

Taw qhia rau kab rov tav lub tshuab nqus tsev nruam casting tshuab

Kab rov tav nqus nruam casting tshuab yog cov cuab yeej siv siab heev siv los tsim cov khoom zoo, siab precision hlau. Tsis zoo li cov txheej txheem casting txheej txheem uas cov hlau molten yog poured rau hauv pwm, cov txheej txheem nruam nruam cuam tshuam nrog kev nruam thiab tswj kev ruaj khov ntawm cov hlau hauv lub tshuab nqus tsev.

Cov thev naus laus zis muaj ntau qhov zoo, suav nrog kev txhim kho cov khoom siv kho tshuab, ua kom tiav zoo dua thiab txo cov nqi tsim khoom. Lub tshuab txoj kab rov tav kev taw qhia ua kom muaj txiaj ntsig zoo ntawm cov khoom siv ntev thiab tiaj tus, ua rau nws zoo tagnrho rau kev tsim cov khoom xws li daim hlau, strips thiab rods.

Cov txheej txheem nruam casting pib los ntawm melting cov hlau nyob rau hauv lub cub tawg thiab ces hloov cov hlau molten mus rau lub tshuab casting. Thaum nyob rau hauv lub tshuab, cov hlau molten solidifies mus rau hauv ib tug nruam strand, uas yog ces txiav mus rau tej lengths raws li xav tau. Tag nrho cov txheej txheem yuav siv sij hawm qhov chaw nyob rau hauv lub tshuab nqus tsev tej yam kev mob, kom ntseeg tau tias cov khoom ntawm high-zoo, tsis xws luag-dawb hlau khoom.

Vim li cas thiaj xaiv peb

Rau kab rov tav lub tshuab nqus tsev casters, xaiv tus neeg muag khoom zoo yog qhov tseem ceeb rau kev ua kom zoo thiab kev ntseeg siab ntawm cov khoom siv. Nov yog qee qhov laj thawj vim li cas xaiv peb rau koj qhov kev xav tau casting yog qhov kev txiav txim siab zoo tshaj plaws uas koj tuaj yeem ua:

1. Txiav-ntug tshuab: Peb lub tuam txhab yog nyob rau hauv lub forefront ntawm technological innovation thiab tsis tu ncua siv zog los tsim thiab txhim kho peb kab rov tav lub tshuab nqus tsev casting tshuab. Peb nqis peev ntau rau hauv kev tshawb fawb thiab kev tsim kho kom ntseeg tau tias peb cov cuab yeej ua tau raws li qhov zoo tshaj plaws thiab cov qauv kev ua haujlwm.

2. Kev Xaiv Kev Cai: Peb nkag siab tias txhua qhov kev xav tau casting yog qhov tshwj xeeb thiab ib qho loj tsis haum rau txhua qhov. Tias yog vim li cas peb muab ntau yam kev xaiv rau customization tailor peb cov cav tov casting rau peb cov neeg muas zaub 'kev xav tau tshwj xeeb. Txawm hais tias nws yog qhov loj, muaj peev xwm lossis kev ua haujlwm, peb tuaj yeem hloov kho peb cov tshuab kom tau raws li koj qhov tshwj xeeb.

3. Kev Pov Hwm Zoo: Kev ua tau zoo yog peb qhov tseem ceeb tshaj plaws thiab peb ua raws li kev tswj hwm nruj ntawm txhua theem ntawm kev tsim khoom. Los ntawm kev xaiv cov khoom siv raw mus rau qhov kawg ntawm cov khoom siv, peb xyuas kom meej tias peb cov kab rov tav lub tshuab nqus tsev casters ua tau raws li cov qauv zoo tshaj plaws thiab kev ntseeg siab.

4. Kev txawj ntse thiab kev paub: Nrog xyoo dhau los ntawm kev lag luam, peb pab pawg kws tshaj lij muaj kev paub thiab kev txawj ntse los muab kev txhawb nqa thiab kev taw qhia rau peb cov neeg siv khoom. Txawm hais tias nws yog kev pabcuam, kev teeb tsa lossis kev saib xyuas, peb tau cog lus los muab kev pabcuam tshwj xeeb thiab kev txhawb nqa.

5. Cov kev daws teeb meem raug nqi: Peb nkag siab qhov tseem ceeb ntawm kev ua tau zoo ntawm cov nqi hauv kev lag luam niaj hnub no. Peb cov kab rov tav lub tshuab nqus tsev casters yog tsim los muab cov kev daws teeb meem zoo thiab kev lag luam los pab peb cov neeg siv khoom txhim kho lawv cov txheej txheem tsim khoom thiab txo cov nqi tag nrho.

6. Cov neeg siv khoom txaus siab: Cov neeg siv khoom txaus siab yog qhov tseem ceeb tshaj plaws hauv peb lub tuam txhab. Peb ua qhov tseem ceeb ntawm kev sib txuas lus qhib, pob tshab thiab kev ua haujlwm kom ntseeg tau tias peb cov neeg siv khoom xav tau tau ntsib mus rau qib siab tshaj plaws. Peb tau cog lus los tsim kev sib raug zoo mus ntev nrog peb cov neeg siv khoom raws li kev ntseeg siab thiab kev ntseeg siab.

7. Kev txhawb nqa tom qab muag: Peb qhov kev cog lus rau peb cov neeg siv khoom mus dhau qhov kev muag khoom. Peb muab kev txhawb nqa tom qab muag nrog rau cov kev pabcuam tu, khoom seem thiab kev pabcuam kev pabcuam kom ntseeg tau tias kev ua haujlwm zoo ntawm lub tshuab nqus tsev vacuum txuas ntxiv mus.

Hauv cov ntsiab lus, kab rov tav lub tshuab nqus tsev casters yog qhov kev ua si hloov pauv rau kev lag luam hlau casting, xa cov khoom tsis sib xws, zoo thiab ua haujlwm zoo. Peb lub tuam txhab yog ib tug txhim khu kev qha thiab tshiab tus khub thaum nws los txog rau xaiv ib tug tsum rau koj casting xav tau kev pab. Nrog peb cov thev naus laus zis thev naus laus zis, kev xaiv kev xaiv, kev lees paub zoo, kev txawj ntse, kev daws teeb meem zoo, cov neeg siv khoom txaus siab thiab kev txhawb nqa tom qab muag, peb yog qhov kev xaiv zoo tshaj plaws rau tag nrho koj cov kev xav tau ntawm lub tshuab nqus tsev vacuum. Ua ib qho kev paub xaiv thiab xaiv peb rau txoj kev ua haujlwm zoo thiab ua tiav.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur