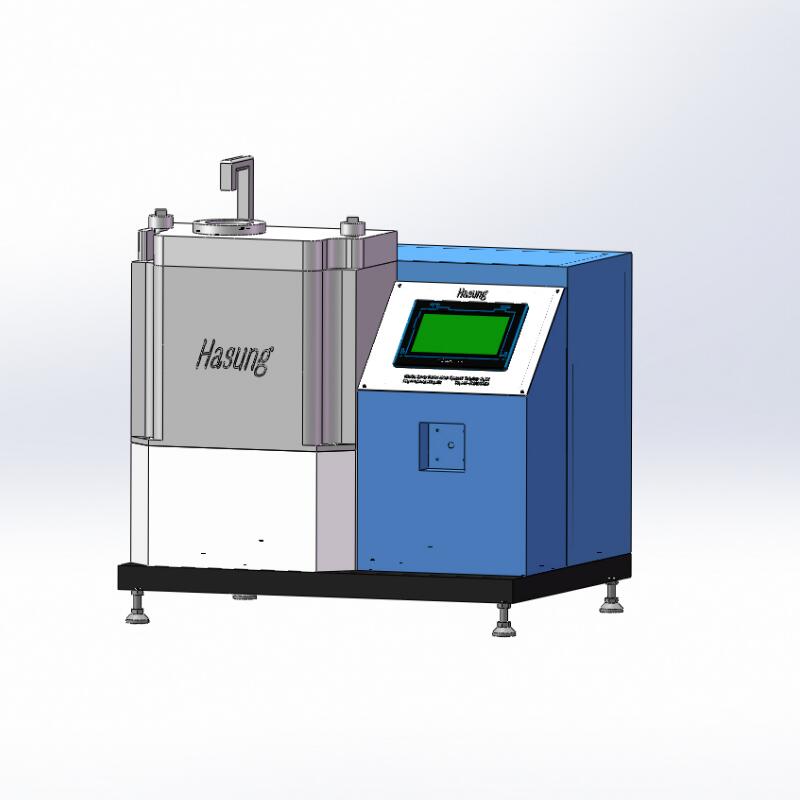

Mini Vacuum Pressure Casting Tshuab rau Platinum Palladium Steel Kub Nyiaj

Nta

1. ntse jewelery nqus siab casting khoom Shenzhen Hasung Precious Metals Equipment Co., Ltd yog tshwj xeeb uas tsim los tsim precious hlau casting thiab melting khoom nrog thawj chav kawm ntawv zoo nyob rau hauv Suav teb.

2. Siv cov cuab yeej siv hluav taws xob ntau zaus, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv thev naus laus zis, nws tuaj yeem yaj hauv lub sijhawm luv luv, txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, thiab kev ua haujlwm siab.

3. Cov hom kaw + lub tshuab nqus tsev / inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab tiv thaiv kev sib xyaw ntawm impurities. Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim.

4. Siv lub kaw + lub tshuab nqus tsev / inert roj tiv thaiv lub tshuab melting chamber, melting thiab nqus tsev vacuuming tib lub sij hawm, lub sij hawm yog halved, thiab ntau lawm efficiency zoo heev.

5. Melting nyob rau hauv ib tug inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon crucible yuav luag negligible.

6. Nrog rau electromagnetic stirring muaj nuj nqi nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

7. Nws txais kev pov thawj yuam kev (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim rau kev siv.

8. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C).

9. HS-MC lub tshuab nqus tsev twj tso kua mis yog tsim los ntawm nws tus kheej thiab tsim los ntawm cov cuab yeej siv siab heev thiab tau mob siab rau cov melting thiab casting ntawm platinum, palladium, stainless hlau, kub, nyiaj, tooj liab thiab lwm yam alloys.

10. Cov khoom siv no siv Mitsubishi PLC kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo lub cev muaj zog tsav thiab lwm yam khoom muaj npe nrov hauv tsev thiab txawv teb chaws.

11. Melting, electromagnetic stirring, thiab tub yees nyob rau hauv ib tug kaw + lub tshuab nqus tsev / inert gas tiv thaiv melting chav tsev, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsis tshua muaj poob, tsis muaj pores, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

Hasung Nqus Tshuab Sib Piv Rau Lwm Lub Tuam Txhab

1. Nrog dual-chamber, ib qho rau melting nrog zoo siab, ib qho rau casting nrog tsis zoo siab thiab nqus.

2. Muaj peev xwm loj txog li 350-500g siab tshaj plaws rau platinum.

3. Nruab nrog lub npe nrov Nyiv thiab German cov khoom lag luam.

4. Max. casting siab mus txog 0.3Mpa.

Technical Parameters

| Qauv No. | HS-SVC |

| Qhov hluav taws xob | 220V, 50/60Hz |

| Fais fab mov | 5 KW |

| Max. Kub | 2100 ° C |

| Temp raug | ± 1 ° C |

| Casting siab | 0.1-0.3Mpa (kho.) |

| Max. Peev xwm (Au/Pt) | 350g ua |

| Max. Flaks loj | 3.15 "x 4" (80x102mm) |

| Daim ntawv thov | Platinum, Palladium, Stainless hlau, Kub, nyiaj, tooj liab thiab lwm yam alloys |

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system |

| Tswj System | Taiwan / Siemens PLC + Tib neeg-tshuab interface ntse tswj qhov system |

| Kev Tiv Thaiv Gas | Nitrogen / Argon |

| Lub tshuab nqus tsev twj | suav nrog |

| Hom cua txias | Dej ntws los yog dej chiller (muag nyias) |

| Qhov ntev | 560 x 450 x 680 mm |

| Qhov hnyav | kwv yees. 70kg ua |

| Shipping Nyhav | kwv yees. 120 kg |

Khoom Qhia

Cov hniav nyiaj hniav kub lub tshuab nqus tsev tilting siab casting tshuab yog customized rau yaj thiab cam khwb cia hniav nyiaj hniav kub rau kub, platinum, nyiaj, thiab lwm yam zoo nkauj hlau.

Hasung hniav nyiaj hniav kub casting khoom yog tsim los ntawm me me ntawm cov hniav nyiaj hniav kub casting, hniav nyiaj hniav kub qauv ua, hniav nyiaj hniav kub, thiab ib co precious hlau DIY casting ua hauj lwm hauv tsev lub hom phiaj. Cov khoom siv suav nrog kev nqis peev sib tov, qhov cub burnout, tshuab casting thiab sandblaster. Nws yog kub muag raws li nws ua tiav ntau tus neeg thov uas max. muaj peev xwm mus txog 500 g.

Nws yog qhov zoo tshaj plaws kom muaj tag nrho cov kab nrib pleb rau lub jeweler lossis me me hniav nyiaj hniav kub rhiav.

Tag nrho cov kab casting muaj:

1. 3D tshuab luam ntawv

2. Roj hmab pwm vulcanizer

3. Wax injector

4. Mini peev lub tshuab nqus tsev tov khoom

5. Lub qhov cub kub

6. Mini lub tshuab nqus tsev siab casting tshuab

7. Cov txheej txheem ntxuav los yog sandblasting thiab polishing.

Lwm cov cuab yeej tsim nyog yog xav tau thaum ua cov hniav nyiaj hniav kub.

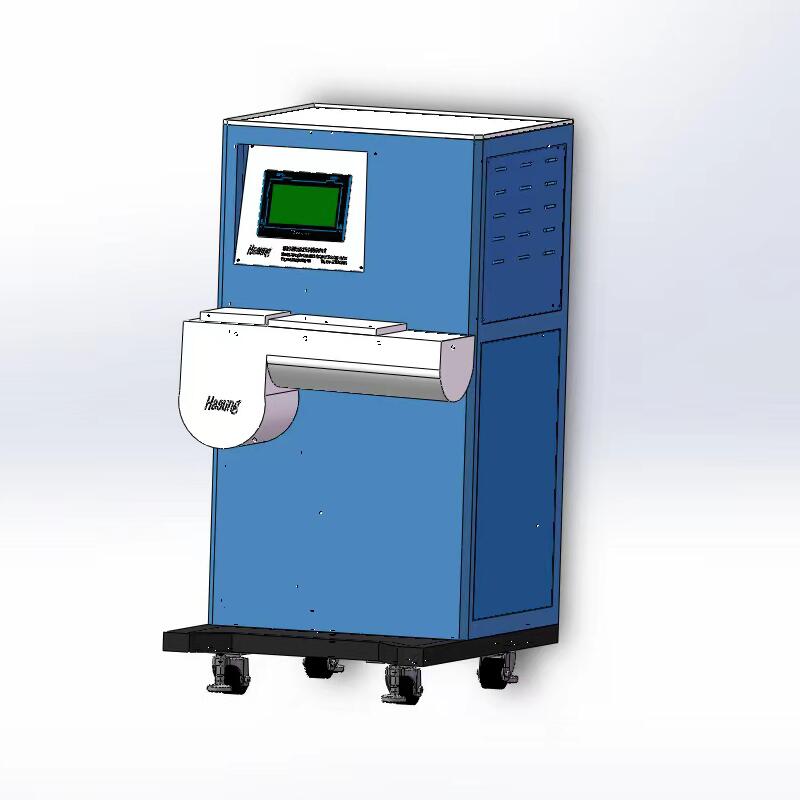

Cov khoom siv nyiaj kub kub (HS-MCK) yog nruab nrog lub tshuab hluav taws xob thiab cov khoom siv hluav taws xob sib cais. Cov pa roj chamber uas tso tawm cov pa roj inert los ntawm lub tshuab melting chamber thiab nqus los ntawm casting chamber tib lub sij hawm uas tshem tawm tag nrho cov porosity thiab oxidation thaum lub sij hawm casting txheej txheem. Qhov no feature uas muab koj zaum kawg cam khwb cia li ib tug hwm zoo casting jewelries.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur