Hasung-High Vacuum Nruam Casting Cov Khoom Siv Rau Cov Hlau Zoo

1, Khoom piav qhia:

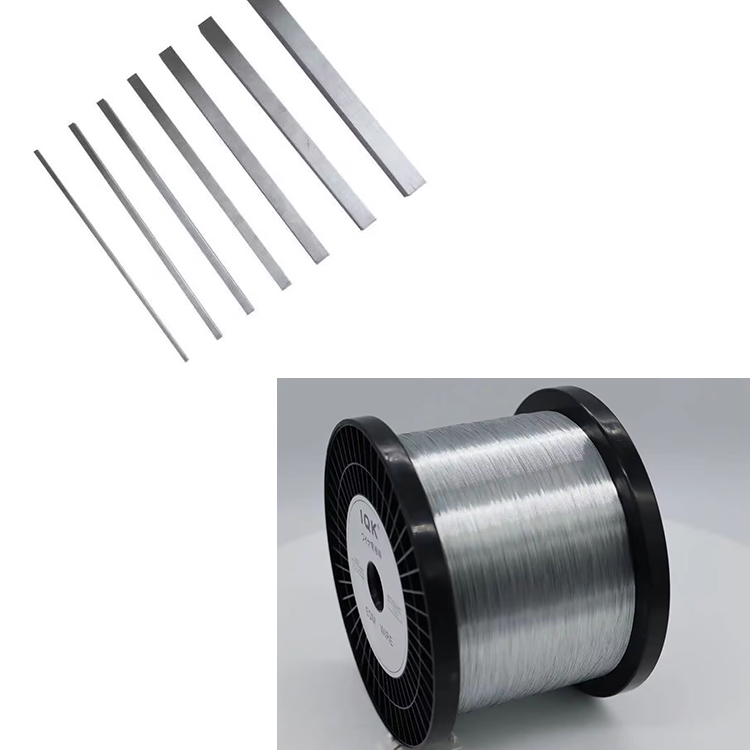

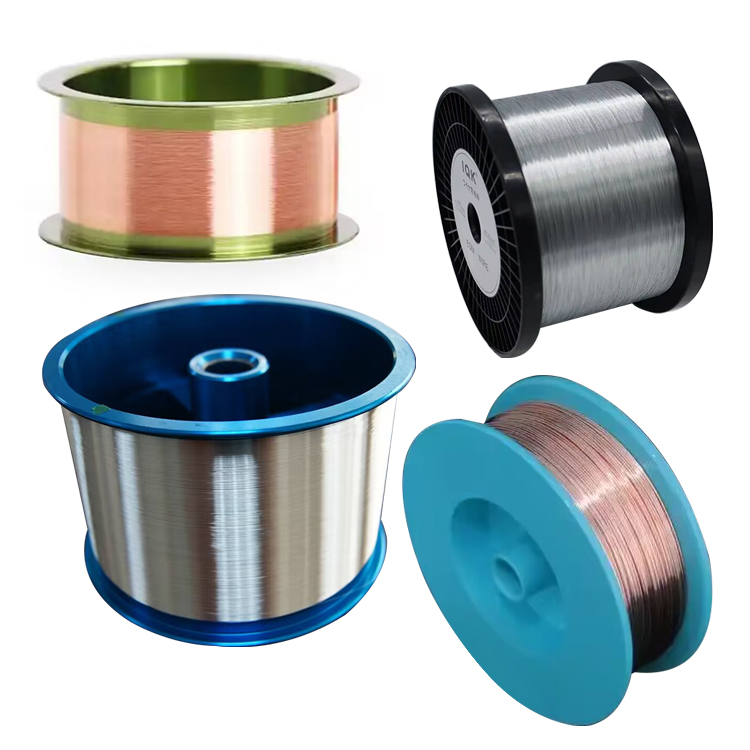

1. Cov khoom siv no tsuas yog siv rau kev nruam nruam ntawm ib leeg siv lead ua tooj liab tuav, ib leeg siv lead ua nyiaj tuav, thiab ib qho siv lead ua kub tuav, thiab tseem tuaj yeem siv rau kev nruam casting ntau lawm ntawm lwm yam hlau thiab alloys.

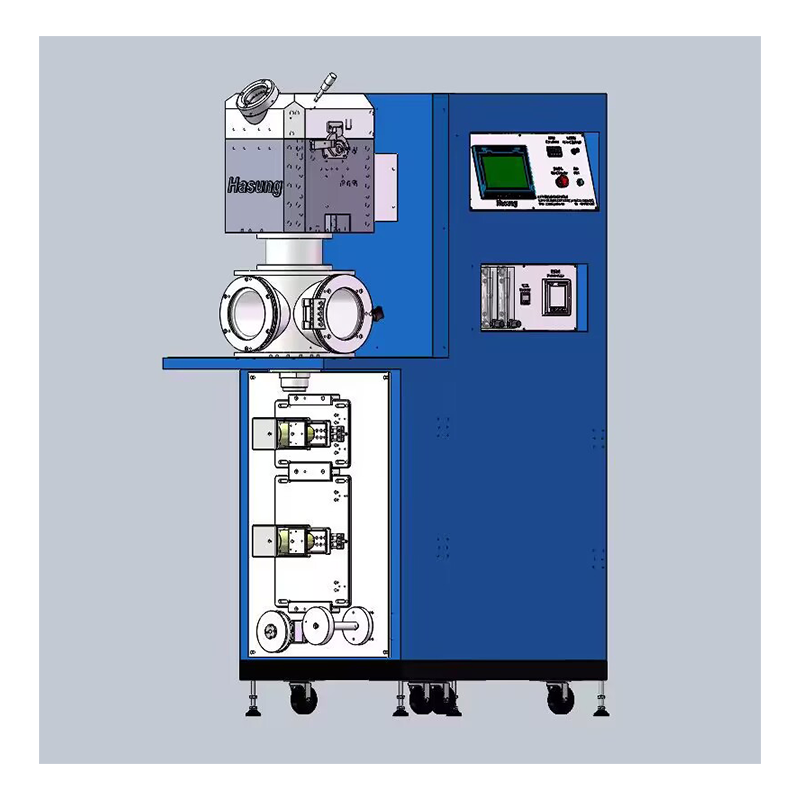

2. Cov khoom siv no yog lub tshuab hluav taws xob ntsug. Cov ntaub ntawv raw, crucible, thiab crystallizer yog muab tso rau hauv lub cub tawg npog qhib los ntawm sab saum toj, thiab cov crystallization qhia pas nrig yog muab tso rau hauv qis qis ntawm lub cub tawg. Ua ntej, cov siv lead ua yog rub tawm ntawm cov yaj los ntawm ib qho ntev los ntawm crystallization qhia pas nrig, thiab tom qab ntawd cov pas nrig siv lead ua yog tsau rau ntawm lub tshuab winding rau kev kos duab thiab sau.

3. Cov cuab yeej no siv lub vijtsam kov tag nrho tsis siv neeg tswj qhov system nrog ntau yam khoom siv saib xyuas kom raug tswj qhov kub thiab txias ntawm lub cub tawg thiab crystallizer, ua tiav cov txheej txheem ruaj khov nyob rau lub sijhawm ntev uas yuav tsum muaj rau kev loj hlob siv lead ua; Kev tiv thaiv ntau yam tuaj yeem ua tau los ntawm kev soj ntsuam cov khoom siv, xws li cov khoom xau los ntawm qhov cub kub kub, lub tshuab nqus tsev tsis txaus, dej hauv siab lossis tsis txaus, thiab lwm yam. Cov cuab yeej siv tau yooj yim rau kev khiav lag luam, thiab cov teeb meem tseem ceeb muaj xws li qhov cub kub, qhov kub thiab txias. sab sauv, nruab nrab, thiab qis ntawm cov crystallizer, ua ntej rub nrawm, siv lead ua kev loj hlob rub ceev (nrog rau hom ntiv tes, uas txhais tau tias rub rau lub sijhawm thiab nres rau lub sijhawm), thiab ntau yam tswb muaj nqis.

Hasung Precious Hlau Siab Tsis Siv Neeg Nruam Casting Tshuab

2, Main technical parameters ntawm cov cuab yeej:

1. Hom: ntsug, tsis siv neeg tswj, tsis siv neeg cua sov.

2. Tag nrho cov fais fab mov voltage: peb-theem 380V, 50Hz peb-theem

3. Lub zog cua sov: 20KW

4. Cua sov txoj kev: induction cua sov (noiseless)

5. Nyhav: 8kg (kub)

6. Lub sij hawm melting: 3-6 feeb

7. Qhov kub siab tshaj plaws: 1600 degrees Celsius

6. Copper pas nrig txoj kab uas hla: 6-10m

7. Lub tshuab nqus tsev kawm ntawv: Lub xeev txias <6 67 × 10-3Pa

8. Kub: 1600 ℃

9. Copper pas nrig rub ceev: 100-1500mm / min (adjustable)

10. Castable hlau: kub, nyiaj, tooj liab, thiab alloy cov ntaub ntawv.

11. Txias txoj kev: Dej txias (dej kub 18-26 degrees Celsius)

12. Tswj hom: Siemens PLC + kov lub vijtsam ntse tswj

13. Khoom siv loj: 2100 * 1280 * 1950mm

14. Nyhav: kwv yees li 1500kg. Lub tshuab nqus tsev siab: kwv yees li 550kg.

3 、 Lub ntsiab lus piav qhia:

1. Lub cev cub hluav taws xob: Lub tshuab hluav taws xob lub cev tau txais cov qauv ntsug ob txheej txheej dej txias. Lub npog qhov cub tuaj yeem qhib tau yooj yim rau kev nkag ntawm crucibles, crystallizers, thiab cov ntaub ntawv raw. Muaj qhov pom qhov rais nyob rau sab sauv ntawm lub qhov cub npog, uas tuaj yeem soj ntsuam qhov xwm txheej ntawm cov khoom molten thaum lub sij hawm melting txheej txheem. Induction electrode flanges thiab lub tshuab nqus tsev flanges yog symmetrically teem ntawm qhov sib txawv qhov siab nyob rau hauv nruab nrab ntawm lub cub tawg lub cev los qhia induction electrode pob qij txha thiab txuas nrog lub tshuab nqus tsev vacuum. Lub tshuab hluav taws xob hauv qab phaj yog nruab nrog lub crucible txhawb nqa, uas tseem ua haujlwm ruaj khov kho kom raug txoj hauj lwm ntawm crystallizer, kom ntseeg tau tias qhov chaw nruab nrab ntawm lub crystallizer yog concentric nrog lub sealing channel ntawm lub cub tawg hauv qab phaj. Txwv tsis pub, tus pas nrig qhia crystallization yuav tsis tuaj yeem nkag mus rau sab hauv ntawm crystallizer los ntawm kev sib khi channel. Muaj peb lub nplhaib dej-txias rau ntawm tus ncej txhawb nqa, sib haum rau sab saud, nruab nrab, thiab qis ntawm cov crystallizer. Qhov kub ntawm txhua feem ntawm crystallizer yog tswj los ntawm kev tswj cov dej ntws ntawm cov dej txias. Muaj plaub lub thermocouples ntawm tus ncej txhawb nqa, uas yog siv los ntsuas qhov kub thiab txias ntawm sab saud, nruab nrab, thiab qis ntawm qhov crucible thiab crystallizer, raws li. Lub interface ntawm lub thermocouples thiab sab nraud ntawm lub cub tawg yog nyob rau ntawm lub cub tawg hauv qab phaj. Lub thawv tso tawm tuaj yeem muab tso rau hauv qab ntawm qhov kev txhawb nqa los tiv thaiv qhov kub thiab txias los ntawm kev ntws ncaj qha los ntawm lub tshuab ntxhua khaub ncaws thiab ua rau lub cev puas tsuaj. Kuj tseem muaj ib qho detachable me me coarse nqus chamber nyob rau hauv qhov chaw nruab nrab ntawm lub phaj hauv qab ntawm lub cub tawg. Hauv qab ntawm lub tshuab nqus tsev coarse chamber yog cov organic iav chamber uas tuaj yeem ntxiv nrog cov tshuaj tiv thaiv oxidation los txhim kho lub tshuab nqus tsev sealing ntawm cov hlau zoo. Cov khoom siv tuaj yeem ua tiav cov nyhuv oxidation ntawm qhov chaw ntawm tus pas nrig tooj liab los ntawm kev ntxiv cov tshuaj tiv thaiv oxidation rau cov organic iav kab noj hniav.

2. Crucible thiab Crystallizer: Lub crucible thiab crystallizer yog ua los ntawm high-purity graphite. Hauv qab ntawm lub crucible yog conical thiab txuas nrog crystallizer los ntawm threads.

3. Lub tshuab nqus tsev:

1. Lub twj tso kua mis

2. Pneumatic siab lub tshuab nqus tsev disc valve

3. Electromagnetic siab nqus vacuum valve

4. Lub tshuab nqus tsev siab

5. Tsawg lub tshuab nqus tsev ntsuas

6. Rauv lub cev

7. Pneumatic siab nqus baffle valve

8. Txias ntxiab

9. Diffusion twj tso kua mis

4. Kev kos duab thiab winding mechanism: Lub nruam casting ntawm tooj liab tuav muaj cov kev taw qhia log, precision ntsia hlau rods, linear guides, thiab winding mechanisms. Lub log coj lub luag haujlwm ua lub luag haujlwm coj thiab ua haujlwm, thiab thawj qhov uas tus pas tooj liab hla dhau thaum nws tawm ntawm lub cub tawg yog lub log tsheb. Lub crystallization qhia pas nrig yog tsau ntawm precision ntsia hlau thiab linear qhia ntaus ntawv. Cov pas nrig tooj liab yog thawj zaug rub tawm ntawm lub tshuab hluav taws xob lub cev (ua ntej rub) los ntawm txoj kab tawm ntawm cov pas nrig crystallization. Thaum tus pas nrig tooj liab hla dhau ntawm lub log qhia thiab muaj qee qhov ntev, kev sib txuas nrog cov pas nrig crystallization tuaj yeem raug txiav tawm. Tom qab ntawd nws yog tsau rau ntawm lub tshuab winding thiab txuas ntxiv kos tus pas tooj liab los ntawm kev sib hloov ntawm lub tshuab winding. Lub servo lub cev muaj zog tswj cov kab lus tawm thiab kev sib hloov ntawm lub tshuab winding, uas tuaj yeem tswj tau qhov nruam nruam nrawm ntawm tus pas nrig tooj liab.

5. Lub tshuab hluav taws xob ultrasonic fais fab mov txais German IGBT, uas tsis tshua muaj suab nrov thiab txuag hluav taws xob. Lub qhov dej siv cov cuab yeej tswj qhov kub thiab txias rau programmed cua sov. Hluav taws xob qhov system tsim

Muaj overcurrent, overvoltage tawm tswv yim thiab tiv thaiv circuits.

6. Kev tswj hwm qhov system: Cov cuab yeej no siv lub vijtsam kov tag nrho tsis siv neeg tswj qhov system nrog ntau yam kev soj ntsuam kom raug tswj qhov kub thiab txias ntawm lub cub tawg thiab crystallizer, ua tiav lub sijhawm ntev ruaj khov uas yuav tsum tau ua rau tooj liab pas nrig nruam casting; Kev tiv thaiv ntau yam tuaj yeem ua tau los ntawm kev saib xyuas cov khoom siv, xws li cov khoom xau los ntawm qhov kub thiab txias, lub tshuab nqus tsev tsis txaus, dej hauv siab lossis tsis txaus, thiab lwm yam. Cov cuab yeej siv tau yooj yim rau kev khiav lag luam thiab cov ntsiab lus tseem ceeb tau teeb tsa.

Muaj qhov cub kub, qhov kub thiab txias ntawm sab saud, nruab nrab, thiab qis ntawm crystallizer, pre rub ceev, thiab siv lead ua kev loj hlob rub ceev

Thiab ntau yam tswb muaj nqis. Tom qab teeb tsa ntau yam tsis sib xws, nyob rau hauv cov txheej txheem ntawm cov pas nrig tooj liab nruam casting, tsuav yog kev nyab xeeb

Muab cov pas nrig qhia crystallization, tso cov khoom siv raw, kaw lub qhov rooj rau qhov cub, txiav tawm qhov kev sib txuas ntawm cov pas nrig tooj liab thiab cov pas nrig crystallization, thiab txuas mus rau lub tshuab winding.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur