Nruam Casting Machine

Lub hauv paus ntsiab lus ntawm kev ua haujlwm zoo tib yam ntawm cov tshuab nruam casting yog raws li cov tswv yim zoo xws li peb lub tshuab nqus tsev siab casting tshuab. Hloov cov khoom ua kua rau hauv lub khob koj tuaj yeem tsim / kos daim ntawv, xaim, pas nrig, lossis lub raj los ntawm kev siv cov pwm graphite. Tag nrho cov no tshwm sim tsis muaj cua npuas los yog shrinking porosity. Lub tshuab nqus tsev thiab lub tshuab nqus tsev siab nruam casting yog siv los ua cov xov hlau zoo xws li kev sib txuas cov hlau, semiconductor, aerospace teb.

-

Hasung-High Vacuum Nruam Casting Cov Khoom Siv Rau Cov Hlau Zoo

Siv tau cov hlau:cov khoom siv hlau xws li kub, K kub, nyiaj, tooj liab, thiab lawv cov alloys

Daim ntawv thov kev lag luam:bonding hlau cov ntaub ntawv, hniav nyiaj hniav kub casting, precious hlau ua, tsev kawm ntawv kuaj thiab lwm yam hauj lwm

Khoom zoo:

1. Lub tshuab nqus tsev siab (6.67 × 10-3pa), cov khoom lag luam siab ntom, tsis muaj cov ntsiab lus oxygen, cov khoom siv tsis muaj txiaj ntsig, haum rau kev tsim cov lag luam hluav taws xob siab;

2. Anti oxidation, inert gas tiv thaiv refining, los daws qhov teeb meem ntawm alloy oxidation;

3. Uniform xim, electromagnetic thiab lub cev stirring txoj kev ua rau cov xim alloy ntau uniform;

4. Cov khoom tiav lawm muaj ib tug du nto thiab txais ib tug downward rub tsim. Lub log traction tau raug kho tshwj xeeb, thiab cov khoom tiav tsis muaj kev puas tsuaj rau saum npoo thiab du nto;

5. Kev tswj qhov kub thiab txias ± 1 ℃, siv cov ntsuas kub ntawm cov ntsuas kub thiab ntse PID tswj qhov ntsuas kub, nrog qhov kub sib txawv ntawm ± 1 ℃;

6. 7-nti puv-xim kov npo, yooj yim dua los saib / kov, qhov system tshiab, yooj yim UI interface, yooj yim rau kev khiav lag luam nrog ib qho kov;

7. Ntau yam kev tiv thaiv, ntau yam kev tiv thaiv kev ruaj ntseg, kev txhawj xeeb tsis siv

-

Precious Hlau Kab rov tav Vacuum Nruam Casting Tshuab

Kab rov tav nqus nruam casting tshuab Zoo

1. Txhim kho cov khoom zoo

2. Txhim kho cov txheej txheem tswj

3. Ua kom muaj zog ntxiv

4. Zog efficiency

Cov yam ntxwv ntawm kab rov tav lub tshuab nqus tsev nruam casting tshuab

1. Kab rov tav Casting Design

2. Lub tshuab nqus tsev vacuum

3. Cua txias system

4. Automation thiab tswj qhov system

5. Loj melting peev xwm

6. Zoo zoo casting khoom

-

Nruam Casting Tshuab rau kub Silver Copper Alloy 20kg 30kg 50kg 100kg

1.As sai li sai tau nyiaj kub sawb hlau raj pas nrignruam casting tshuabrau cov hniav nyiaj hniav kub tau nthuav tawm ntawm kev ua lag luam, nws tau txais cov lus pom zoo los ntawm ntau tus neeg siv khoom, uas tau hais tias cov khoom siv no tuaj yeem daws lawv cov kev xav tau zoo. Ntxiv mus, cov khoom siv dav siv hauv Hlau Casting.

2.Nruam Casting Tshuab rau Ua Qws Sawb Yeeb Nkab nrog 20kg 30kg 50kg 100kg piv nrog cov khoom zoo sib xws ntawm kev ua lag luam, nws muaj qhov zoo sib xws ntawm kev ua tau zoo, zoo, tsos, thiab lwm yam, thiab nyiam lub koob npe nrov hauv khw.Hasung qhia txog qhov tsis xws luag ntawm cov khoom yav dhau los, thiab txuas ntxiv txhim kho lawv. Cov specifications ntawm Nruam Casting Tshuab rau Ua Qws Sawb Yeeb Nkab nrog 20kg 30kg 50kg 100kg tuaj yeem kho raws li koj xav tau.

-

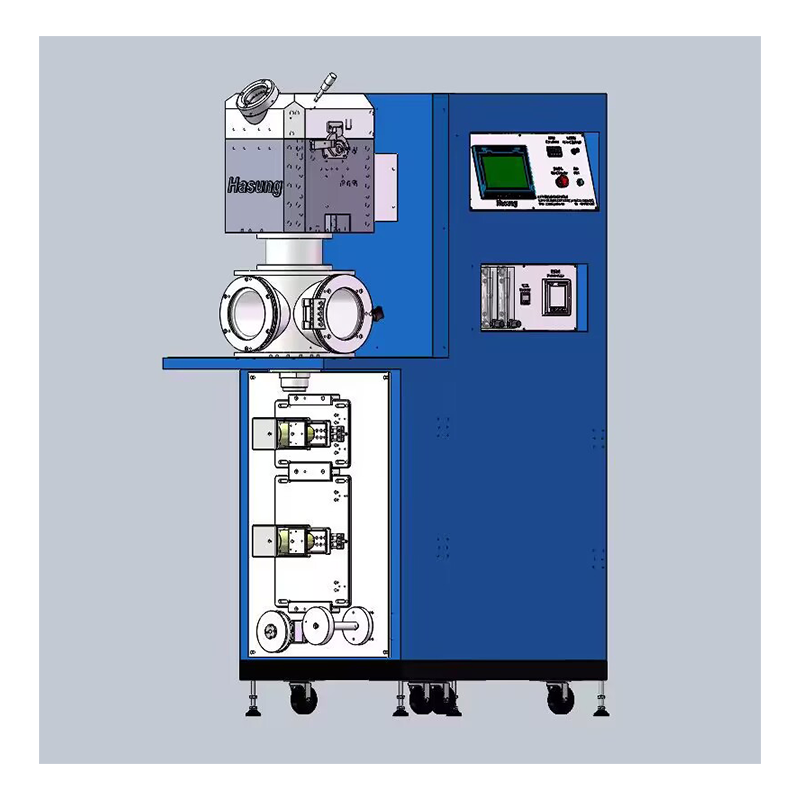

High Vacuum Nruam Casting Tshuab Rau Cov Khoom Tshiab Casting Bonding Kub Nyiaj Tooj Hlau Hlau

Casting ntawm cov khoom siv hluav taws xob xws li daim ntawv cog lus alloy nyiaj tooj liab hlau thiab high-purity tshwj xeeb xaim Kev tsim cov cuab yeej siv no yog ua raws li qhov xav tau tiag tiag ntawm qhov project thiab txheej txheem, thiab ua kom siv tag nrho cov cuab yeej siv niaj hnub high-tech.

1. Txais German high-frequency cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv technology, uas yuav yaj nyob rau hauv ib tug luv luv lub sij hawm, txuag lub zog thiab ua hauj lwm zoo.

2. Hom kaw + inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab sib tov ntawm impurities. Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim.

3. Siv kaw + inert gas los tiv thaiv lub melting chamber. Thaum melting nyob rau hauv ib qho inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon pwm yog yuav luag negligible.

4. Nrog kev ua haujlwm ntawm electromagnetic stirring + mechanical stirring nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

5. Siv cov ntaub ntawv pov thawj yuam kev (tiv thaiv kev dag) tsis siv neeg tswj qhov system, kev ua haujlwm yooj yim dua.

6. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C).

7. HVCC series siab nqus nruam casting khoom yog nws tus kheej tsim thiab tsim, nrog cov cuab yeej siv siab heev, siv rau kev nruam nruam ntawm siab purity kub, nyiaj, tooj liab thiab lwm yam alloys.

8. Cov khoom siv no siv Mitsubishi PLC kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo tsav tsav thiab lwm yam khoom siv hauv tsev thiab txawv teb chaws.

9. Melting nyob rau hauv ib tug kaw + inert gas tiv thaiv melting chav tsev, muab ob npaug rau noj, electromagnetic stirring, mechanical stirring, tub yees, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj porosity, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

10. Nqus Hom: Lub tshuab nqus tsev siab.

-

Nqus Nruam Casting Tshuab rau Kub Nyiaj Copper Alloy

Cim lub tshuab nqus tsev nruam casting system

Rau siab tshaj plaws ntawm cov khoom semi-tiav:

Txhawm rau txo qhov kev pheej hmoo ntawm oxidation thaum lub sij hawm melting thiab thaum lub sij hawm kos duab, peb tsom ntsoov rau kev tsis txhob muaj cov pa oxygen thiab txo qhov kub thiab txias ntawm cov khoom siv hlau.

Nta kom tsis txhob muaj pa oxygen:

1. Inert gas system rau lub melting chamber

2. Lub tshuab nqus tsev rau lub melting chamber - tshwj xeeb muaj rau Hasung nqus nruam casting tshuab (VCC series)

3. Inert gas flushing ntawm qhov tuag

4. Optical tuag kub ntsuas

5. Ntxiv qhov cua txias thib ob

6. Tag nrho cov kev ntsuas no yog qhov zoo tshaj plaws rau cov alloys uas muaj tooj liab xws li kub liab los yog nyiaj, vim cov ntaub ntawv no nyiam oxidise yooj yim.Cov txheej txheem kos duab thiab qhov xwm txheej tuaj yeem pom tau yooj yim los ntawm kev soj ntsuam qhov rais.

Lub tshuab nqus tsev degrees tuaj yeem ua raws li cov neeg siv khoom thov.

-

Nruam Casting Tshuab rau Kub Silver Copper Alloy

Kev tsim cov cuab yeej siv no yog ua raws li qhov xav tau tiag tiag ntawm qhov project thiab txheej txheem, siv cov cuab yeej siv niaj hnub high-tech.

1. Siv German high-frequency cua sov tshuab, tsis siv neeg zaus taug qab thiab ntau yam kev tiv thaiv technologies, nws yuav yaj nyob rau hauv ib tug luv luv lub sij hawm, lub zog txuag thiab kev tiv thaiv ib puag ncig, thiab ua hauj lwm efficiency.

2. Hom kaw + inert roj tiv thaiv melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab tiv thaiv kev sib xyaw ntawm impurities. Cov cuab yeej no tsim nyog rau cov khoom siv hlau purity siab lossis oxidized elemental hlau yooj yim.

3. Siv lub kaw + inert roj tiv thaiv melting chamber, melting thiab nqus tsev vacuuming tib lub sij hawm, lub sij hawm yog halved, thiab ntau lawm efficiency yog heev txhim khu kev qha.

4. Melting nyob rau hauv ib tug inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon crucible yuav luag negligible.

5. Nrog rau electromagnetic stirring muaj nuj nqi nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

6. Nws txais qhov yuam kev pov thawj (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim rau kev siv.

7. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C). HS-CC series nruam casting khoom yog tus kheej tsim thiab tsim nrog cov thev naus laus zis siab tshaj plaws thiab muaj nplooj siab rau melting thiab casting kub, nyiaj, tooj liab thiab lwm yam alloys strips, rods, nplooj ntawv, kav, thiab lwm yam.

8. Cov cuab yeej siv no siv Mitsubishi PLC kev tswj hwm qhov system, SMC pneumatic thiab Panasonic servo tsav tsav thiab lwm yam khoom lag luam muaj npe nrov hauv tsev thiab txawv teb chaws.

9. Melting, electromagnetic stirring, thiab tub yees nyob rau hauv ib tug kaw + inert gas tiv thaiv melting chav tsev, yog li ntawd cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj pores, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

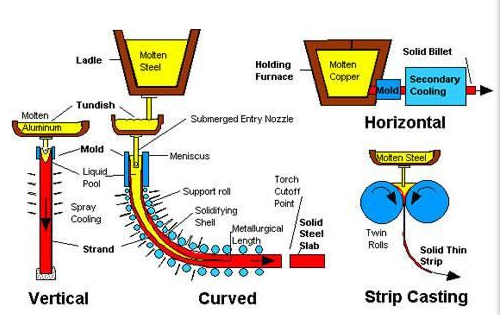

Dab tsi yog qhov nruam casting, nws yog dab tsi, qhov zoo yog dab tsi?

Cov txheej txheem nruam nruam yog ib txoj hauv kev zoo heev los tsim cov khoom lag luam ib nrab xws li tuav, profiles, slabs, strips thiab hlab ua los ntawm kub, nyiaj thiab cov hlau tsis muaj hlau xws li tooj liab, txhuas thiab alloys.

Txawm hais tias muaj cov txheej txheem nruam nruam sib txawv, tsis muaj qhov sib txawv tseem ceeb hauv casting kub, nyiaj, tooj liab lossis alloys. Qhov sib txawv tseem ceeb yog qhov ntsuas kub ntawm qhov ntsuas kub ntawm kwv yees li 1000 ° C nyob rau hauv cov ntaub ntawv ntawm cov nyiaj los yog tooj liab mus rau 1100 ° C nyob rau hauv cov ntaub ntawv ntawm kub los yog lwm yam alloys. Cov hlau molten yog nruam nruam mus rau hauv lub nkoj cia hu ua ladle thiab ntws los ntawm qhov ntawd mus rau hauv ib qho ntsug lossis kab rov tav casting pwm nrog qhib kawg. Thaum ntws los ntawm cov pwm, uas yog txias nrog crystallizer, cov kua loj yuav siv sij hawm qhov profile ntawm cov pwm, pib solidify ntawm nws nto thiab tawm cov pwm nyob rau hauv ib tug semi-khoom strand. Nyob rau tib lub sijhawm, cov yaj tshiab yog tas li nkag mus rau cov pwm ntawm tib tus nqi kom ua raws li cov khoom sib khi tawm hauv pwm. Cov strand yog ntxiv txias los ntawm kev siv dej txau. Los ntawm kev siv cov txias txias nws muaj peev xwm ua rau kom qhov ceev ntawm crystallization thiab tsim nyob rau hauv lub strand ib homogeneous, nplua-grained qauv muab cov semi-tiav khoom zoo technological zog. Tom qab ntawd lub solidified strand yog straightened thiab txiav mus rau qhov ntev ntev los ntawm txiav los yog ib tug txiav-teeb.

Cov ntu tuaj yeem ua haujlwm ntxiv rau hauv kev ua haujlwm tom ntej hauv-kab dov kom tau txais cov khoom tuav, rods, extrusion billets (blanks), slabs lossis lwm yam khoom ua tiav hauv ntau qhov ntev.

Keeb kwm ntawm nruam casting

Thawj qhov kev sim ua cov hlau hauv cov txheej txheem txuas ntxiv tau ua nyob rau hauv nruab nrab ntawm lub xyoo pua 19th. Xyoo 1857, Sir Henry Bessemer (1813–1898) tau txais patent rau casting hlau ntawm ob contra-rotating rollers rau kev tsim hlau slabs. Tab sis lub sij hawm ntawd tus qauv no tseem tsis tau mloog. Kev txiav txim siab tau ua tiav los ntawm xyoo 1930 txuas ntxiv nrog cov txheej txheem Junghans-Rossi rau kev nruam nruam ntawm lub teeb thiab hnyav hlau. Hais txog hlau, cov txheej txheem nruam nruam tau tsim nyob rau xyoo 1950, ua ntej (thiab tom qab) cov hlau tau nchuav rau hauv pwm ruaj khov los tsim 'ingots'.

Kev nruam nruam ntawm cov pas nrig tsis-ferrous yog tsim los ntawm cov txheej txheem Properzi, tsim los ntawm Ilario Properzi (1897-1976), tus tsim ntawm lub tuam txhab Continuus-Properzi.

Qhov zoo ntawm kev nruam casting

Nruam casting yog txoj hauv kev zoo tshaj plaws rau kev tsim cov khoom lag luam ib nrab ntawm qhov ntev thiab ua rau cov khoom loj hauv lub sijhawm luv. Lub microstructure ntawm cov khoom yog txawm. Piv nrog rau casting hauv pwm, nruam casting yog kev lag luam ntau txog kev siv lub zog thiab txo cov seem tsawg. Tsis tas li ntawd, cov khoom ntawm cov khoom tuaj yeem hloov kho tau yooj yim los ntawm kev hloov pauv cov khoom pov thawj. Raws li tag nrho cov kev khiav hauj lwm tuaj yeem ua tau zoo thiab tswj tau, nruam casting muaj ntau txoj hauv kev los hloov cov khoom lag luam hloov pauv sai thiab nrawm rau kev hloov pauv kev lag luam thiab ua ke nrog digitization (Industrie 4.0) technologies.