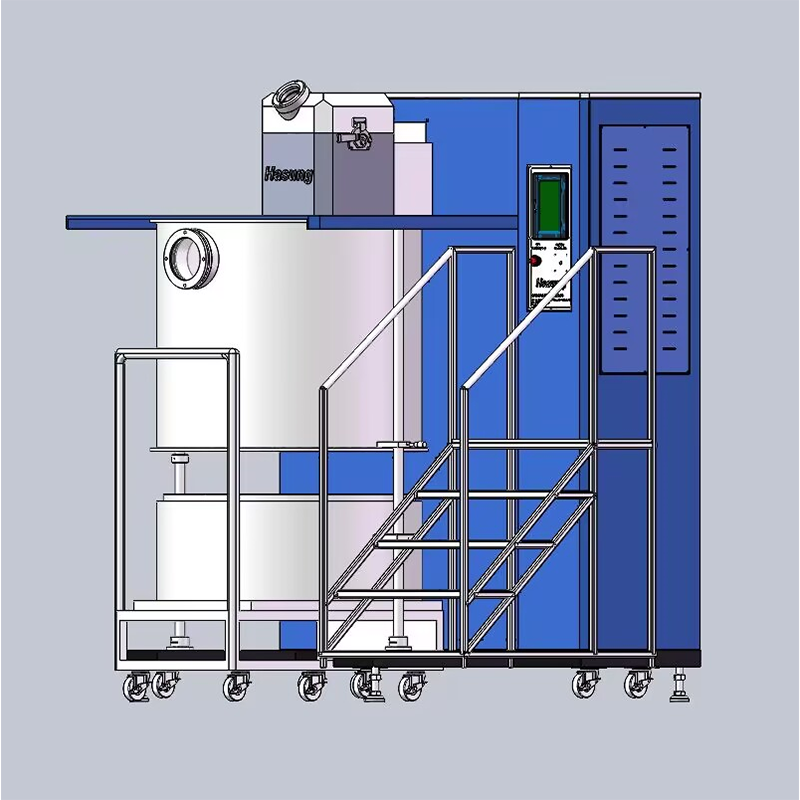

100 mesh - 400 mesh Hlau Powder Dej Atomizer Tshuab

Technical Parameters

| Qauv No. | HS-MGA 5 | HS-MGA 10 | HS-MGA 30 | HS-MGA 50 | HS-MGA 100 |

| Qhov hluav taws xob | 380V 3 theem, 50/60Hz | ||||

| Fais fab mov | 15 KW | 30 KW | 30KW/50KW TSI | 60 kWm | |

| Peev xwm (Au) | 5kg ua | 10kg ua | 30kg ua | 50kg ua | 100 kg |

| Max Temp. | 1600 ° C / 2200 ° C | ||||

| Lub sijhawm yaj | 3-5 feeb. | 5-8 feeb. | 5-8 feeb. | 6-10 feeb. | 15-20 feeb. |

| Particle grains (Mesh) | 200 # - 300 # - 400 # | ||||

| Temp raug | ± 1 ° C | ||||

| Lub tshuab nqus tsev twj | Lub tshuab nqus tsev nqus tsev vacuum qib siab zoo | ||||

| Ultrasonic system | High quality Ultrasonic system tswj qhov system | ||||

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | ||||

| Tswj System | Mitsubishi PLC + Tib neeg-tshuab interface ntse tswj qhov system | ||||

| Inert gas | Nitrogen / Argon | ||||

| Hom cua txias | Dej chiller (muag nyias) | ||||

| Qhov ntev | kwv yees. 3575 * 3500 * 4160mm | ||||

| Qhov hnyav | kwv yees. 2150kg ib | kwv yees. 3000 kg | |||

Atomization pulverizing txoj kev yog txheej txheem tshiab tsim nyob rau hauv cov hmoov metallurgy kev lag luam nyob rau hauv xyoo tas los. Nws muaj qhov zoo ntawm cov txheej txheem yooj yim, thev naus laus zis yooj yim rau tus tswv, cov khoom siv tsis yooj yim rau oxidized, thiab qib siab ntawm automation.

1. Cov txheej txheem tshwj xeeb yog tias tom qab cov hlau (hlau) yog yaj thiab ua kom zoo nyob rau hauv lub qhov cub induction, cov kua hlau molten yog nchuav rau hauv cov cua kub preservation crucible thiab nkag mus rau hauv lub raj thiab nozzle. Thaum lub sij hawm no, cov yaj ntws yog thaiv los ntawm cov kua dej siab siab (lossis cov roj ntws) Cov hmoov hlau atomized thiab atomized yog solidified thiab nyob rau hauv atomization ntauwd, thiab ces poob rau hauv cov hmoov ntim tank rau kev sau thiab sib cais. Nws yog dav siv nyob rau hauv lub tshav pob ntawm non-ferrous hlau hmoov ua xws li atomized hlau hmoov, tooj liab hmoov, stainless hlau hmoov thiab alloy hmoov. Kev tsim tshuab ntawm kev ua tiav cov khoom siv hlau hmoov, cov khoom siv tooj liab hmoov, cov khoom siv nyiaj hmoov thiab cov khoom siv hmoov hlau tau dhau los ua neeg paub tab.

2. Siv thiab lub hauv paus ntsiab lus ntawm dej atomization pulverizing cov cuab yeej, dej atomization pulverizing cov cuab yeej yog cov cuab yeej tsim los ua kom tau raws li cov txheej txheem dej atomization pulverizing nyob rau hauv atmospheric tej yam kev mob, thiab nws yog ib tug industrialized loj ntau lawm ntaus ntawv. Lub hauv paus ntsiab lus ua haujlwm ntawm cov khoom siv dej atomization pulverizing yog hais txog kev smelting ntawm cov hlau los yog hlau alloy nyob rau hauv atmospheric tej yam kev mob. Nyob rau hauv cov xwm txheej ntawm kev tiv thaiv roj, cov kua hlau ntws los ntawm cov thermal rwb thaiv tsev tundish thiab cov yeeb nkab sib txawv, thiab cov dej siab ultra-siab ntws los ntawm lub nozzle. Cov hlau ua kua yog atomized thiab tawg mus rau hauv ib tug loj tus naj npawb ntawm nplua hlau tee, thiab cov zoo tee tsim sub-spherical los yog irregular hais nyob rau hauv kev sib xyaw ua ke ntawm nto nro thiab ceev ceev cov dej txias thaum lub sij hawm lub davhlau mus cuag lub hom phiaj ntawm milling.

3. Cov khoom siv dej atomization pulverizing muaj cov yam ntxwv hauv qab no: 1. Nws tuaj yeem npaj cov hlau feem ntau thiab nws cov hmoov hlau alloy, thiab cov nqi tsim khoom tsawg. 2. Subspherical hmoov los yog cov hmoov tsis zoo tuaj yeem npaj tau. 3. Vim yog qhov ruaj khov sai thiab tsis muaj kev sib cais, ntau cov hmoov hlau tshwj xeeb tuaj yeem npaj tau. 4. Los ntawm kev kho cov txheej txheem tsim nyog, cov hmoov particle loj tuaj yeem ncav cuag qhov xav tau ntau yam.

4. Cov qauv ntawm cov dej atomization pulverizing khoom Cov qauv ntawm cov khoom siv atomizing pulverizing muaj cov nram qab no: smelting, tundish system, atomization system, inert gas tiv thaiv system, ultra-siab siab dej system, hmoov sau, lub cev qhuav dej thiab ziab, kev tshuaj ntsuam xyuas, dej txias system, PLC tswj qhov system, platform system, thiab lwm yam. 1. Melting thiab tundish system: Qhov tseeb, nws yog qhov nruab nrab zaus induction melting rauv, uas muaj xws li: plhaub, induction kauj, ntsuas kub, tilting rauv ntaus ntawv, tundish thiab lwm yam: lub plhaub yog ib tug ncej qauv, uas yog carbon ua los ntawm hlau thiab stainless hlau, ib tug induction kauj yog ntsia rau hauv lub nruab nrab, thiab ib tug crucible yog muab tso rau hauv induction kauj, uas yuav smelted thiab poured. Lub tundish tau nruab rau ntawm lub tshuab nozzle, siv los khaws cov kua hlau molten, thiab muaj kev ua haujlwm ntawm kev txuag hluav taws xob. Nws yog me dua lub crucible ntawm lub smelting system. Lub tundish tuav rauv muaj nws tus kheej cua sov system thiab ntsuas kub. Lub tshuab cua sov ntawm lub qhov cub tuav muaj ob txoj hauv kev: cov cua kub tsis kam thiab induction cua sov. Qhov ntsuas kub tsis kam ua kom sov feem ntau tuaj yeem ncav cuag 1000 ℃, thiab qhov cua sov induction tuaj yeem ncav cuag 1200 ℃ lossis siab dua, tab sis cov khoom siv crucible yuav tsum tau xaiv kom tsim nyog. 2. Atomization system: Lub tshuab atomization muaj cov nozzles, cov kav dej siab siab, li qub, thiab lwm yam. 3. Inert gas tiv thaiv system: Nyob rau hauv cov txheej txheem ntawm pulverizing, thiaj li yuav txo tau cov oxidation ntawm hlau thiab alloys thiab txo cov pa oxygen. ntawm cov hmoov, ib co nqi ntawm inert gas feem ntau yog nkag mus rau hauv lub atomization ntauwd rau huab cua tiv thaiv. 4. Ultra-high-pressure water system: Qhov system no yog ib qho khoom siv uas muab cov dej muaj zog rau atomizing nozzles. Nws muaj cov twj tso kua dej siab, lub tank dej, li qub, cov hoses siab siab thiab busbars. 5. Lub tshuab cua txias: Tag nrho cov cuab yeej yog nruab nrog cov dej txias, thiab cov cua txias yog qhov tseem ceeb. Qhov ntsuas kub ntawm cov dej txias yuav raug cuam tshuam los ntawm qhov ntsuas thib ob kom ntseeg tau tias kev ua haujlwm zoo ntawm cov cuab yeej. 6. Kev tswj qhov system: Lub kaw lus tswj yog lub chaw tswj xyuas kev ua haujlwm ntawm lub cuab yeej. Tag nrho cov haujlwm thiab cov ntaub ntawv cuam tshuam raug xa mus rau PLC ntawm lub kaw lus, thiab cov txiaj ntsig tau ua tiav, khaws cia thiab tso tawm los ntawm kev ua haujlwm.

R & D thiab tsim cov cuab yeej tshaj lij rau kev npaj cov khoom siv hmoov tshiab, muab cov kev daws teeb meem rau kev tsim cov khoom siv tshiab tshiab, spherical hmoov npaj tshuab nrog kev ywj pheej cov cuab yeej cuab tam / puag ncig thiab tiaj tus hmoov npaj tshuab / sawb hmoov npaj tshuab / flake hmoov npaj tshuab, nrog rau ultrafine / nano hmoov npaj tshuab, siab tshuaj purity hmoov npaj tshuab.

Txheej Txheem Ua Hlau Hmoov Los Ntawm Dej Atomization Pulverizing Equipment

Cov txheej txheem ntawm kev ua hlau hmoov los ntawm dej atomization pulverizing cov cuab yeej muaj keeb kwm ntev. Nyob rau hauv ancient sij hawm, tib neeg nchuav molten hlau rau hauv dej kom nws tawg mus rau hauv zoo hlau hais, uas yog siv los ua raw khoom rau ua hlau; txog tam sim no, tseem muaj cov neeg uas nchuav cov hmoov txhuas ncaj qha rau hauv dej los ua cov hmoov txhuas. . Siv cov txheej txheem dej atomization los ua cov hmoov coarse alloy, cov txheej txheem txheej txheem yog tib yam li cov lus hais saum toj no cov dej tawg hlau ua kua, tab sis cov pulverization efficiency tau zoo heev.

Cov dej atomization pulverizing cov cuab yeej ua rau coarse alloy hmoov. Ua ntej, cov coarse kub yog melted nyob rau hauv lub cub tawg. Lub melted kub kua yuav tsum tau overheated li ntawm 50 degrees, thiab ces ncuav rau hauv lub tundish. Pib lub twj tso kua dej siab ua ntej cov kua kub yog txhaj, thiab cia lub tshuab nqus dej siab atomization pib lub workpiece. Cov kua kub hauv lub tundish hla lub nqaj thiab nkag mus rau hauv lub atomizer los ntawm lub qhov dej ntws tawm hauv qab ntawm tundish. Atomizer yog cov cuab yeej tseem ceeb rau kev ua cov coarse kub alloy hmoov los ntawm kev kub siab dej pos huab. Qhov zoo ntawm cov atomizer muaj feem xyuam rau cov crushing efficiency ntawm hlau hmoov. Nyob rau hauv qhov kev txiav txim ntawm high-pressure dej los ntawm lub atomizer, cov kua kub yog tsis tu ncua tawg mus rau hauv zoo tee dej, uas poob mus rau hauv lub txias kua nyob rau hauv lub ntaus ntawv, thiab cov kua sai sai solidifies mus rau hauv alloy hmoov. Nyob rau hauv cov txheej txheem ib txwm ua cov hmoov hlau los ntawm kev kub siab dej atomization, cov hmoov hlau tuaj yeem khaws tau tsis tu ncua, tab sis muaj qhov xwm txheej uas cov hmoov hlau me me poob nrog cov dej atomizing. Nyob rau hauv tus txheej txheem ntawm kev ua hmoov txhuas los ntawm high-pressure dej atomization, cov khoom atomized yog concentrated nyob rau hauv lub atomization ntaus ntawv, tom qab nag lossis daus, pom, (yog tias tsim nyog, nws tuaj yeem qhuav, feem ntau ncaj qha xa mus rau cov txheej txheem tom ntej.), kom tau txais hmoov zoo Alloy hmoov, tsis muaj qhov poob ntawm cov hmoov txhuas hauv tag nrho cov txheej txheem.

Cov khoom ua tiav ntawm cov dej atomization pulverizing Cov khoom siv rau kev ua cov hmoov txhuas muaj cov hauv qab no:

Smelting ntu:ib qho nruab nrab zaus hlau smelting rauv los yog ib tug high-frequency hlau smelting rauv yuav xaiv tau. Lub peev xwm ntawm lub cub tawg yog txiav txim siab raws li qhov ntim ntawm cov hmoov hlau, thiab lub qhov cub 50 kg lossis 20 kg tuaj yeem xaiv tau.

Atomization ntu:Cov khoom siv hauv qhov no yog cov khoom siv tsis yog qauv, uas yuav tsum tau tsim thiab npaj raws li qhov chaw ntawm cov chaw tsim khoom. Muaj feem ntau tundishes: thaum tundish yog tsim nyob rau hauv lub caij ntuj no, nws yuav tsum tau preheated; Atomizer: Lub atomizer yuav los ntawm kev kub siab Lub siab-siab dej ntawm lub twj tso kua mis cuam tshuam cov kua kub los ntawm tundish ntawm lub predetermined ceev thiab lub kaum sab xis, rhuav nws mus rau hauv cov tee dej. Nyob rau hauv tib lub twj tso kua dej siab, tus nqi ntawm cov hmoov hlau zoo tom qab atomization muaj feem xyuam rau lub atomization efficiency ntawm lub atomizer; lub tog raj kheej atomization: nws yog qhov chaw uas cov hmoov hlau alloy yog atomized, crushed, txias thiab sau. Txhawm rau tiv thaiv cov hmoov txhuas ultra-nplua hmoov nyob rau hauv cov hmoov hlau uas tau los ntawm kev poob nrog dej, nws yuav tsum tau tso tseg rau lub sijhawm tom qab atomization, thiab tom qab ntawd muab tso rau hauv lub thawv ntim hmoov.

Post-processing ib feem:hmoov sau lub thawv: siv los sau cov hmoov atomized alloy thiab cais thiab tshem tawm cov dej ntau dhau; ziab rauv: qhuav cov hmoov nplej ntub dej nrog dej; Kev tshuaj ntsuam tshuab: sieve cov hmoov txhuas, Tawm ntawm cov lus qhia coarser alloy hmoov tuaj yeem rov ua dua thiab atomized ua cov khoom xa rov qab.

Vacuum Air Atomization Pulverizing Technology Thiab Nws Daim Ntawv Thov

Cov hmoov npaj los ntawm lub tshuab nqus tsev atomization muaj qhov zoo ntawm purity siab, tsis tshua muaj oxygen cov ntsiab lus thiab nplua hmoov particle loj. Tom qab xyoo ntawm kev tsim kho tshiab thiab kev txhim kho tas mus li, lub tshuab nqus tsev atomization hmoov tshuab tau tsim los rau hauv txoj hauv kev tseem ceeb ntawm kev tsim cov hlau thiab alloy hmoov, thiab tau dhau los ua qhov tseem ceeb txhawb thiab txhawb kev tshawb fawb ntawm cov ntaub ntawv tshiab thiab kev tsim cov thev naus laus zis tshiab. Tus editor tau qhia txog lub hauv paus ntsiab lus, txheej txheem thiab cov khoom siv hmoov milling ntawm lub tshuab nqus tsev atomization, thiab tshuaj xyuas hom thiab siv cov hmoov npaj los ntawm lub tshuab nqus tsev atomization.

Txoj kev atomization yog ib txoj kev npaj hmoov nyob rau hauv uas cov kua ceev ceev (atomizing nruab nrab) cuam tshuam los yog lwm yam lov cov hlau los yog alloy kua rau hauv cov dej zoo, uas yog tom qab ntawd condensed rau hauv cov hmoov hmoov. Cov hmoov atomized tsis tsuas yog muaj tib yam tshuaj lom neeg muaj pes tsawg leeg raws li cov khoom siv molten alloy, tab sis kuj vim yog lub zog ceev ceev refines cov qauv crystalline thiab tshem tawm cov macrosegregation ntawm theem ob. Feem ntau siv atomization nruab nrab yog dej los yog ultrasonic, uas yog hu ua dej atomization thiab roj atomization raws li. Cov hmoov hlau npaj los ntawm cov dej atomization muaj cov txiaj ntsig siab thiab kev lag luam tawm, thiab qhov txias txias yog ceev, tab sis cov hmoov muaj cov pa oxygen siab thiab tsis zoo morphology, feem ntau flakes. Cov hmoov npaj los ntawm ultrasonic atomization tshuab muaj me me particle loj, siab sphericity thiab tsis tshua muaj oxygen cov ntsiab lus, thiab tau dhau los ua txoj kev tseem ceeb rau kev ua tau zoo kheej kheej hlau thiab alloy hmoov.

Lub tshuab nqus tsev smelting high-pressure gas atomization pulverizing technology integrates high-vacuum technology, high-temperature smelting technology, high-pressure and high-speed gas technology, thiab yog tsim los ua kom tau raws li cov kev xav tau ntawm kev tsim cov hmoov metallurgy, tshwj xeeb tshaj yog rau kev tsim cov high- zoo alloys uas muaj active ntsiab hmoov. Ultrasonic / Gas atomization pulverizing thev naus laus zis yog lub tshuab tshiab nrawm nrawm. Vim lub siab txias npaum li cas, cov hmoov muaj cov yam ntxwv ntawm grain refinement, uniform muaj pes tsawg leeg thiab siab solubility.

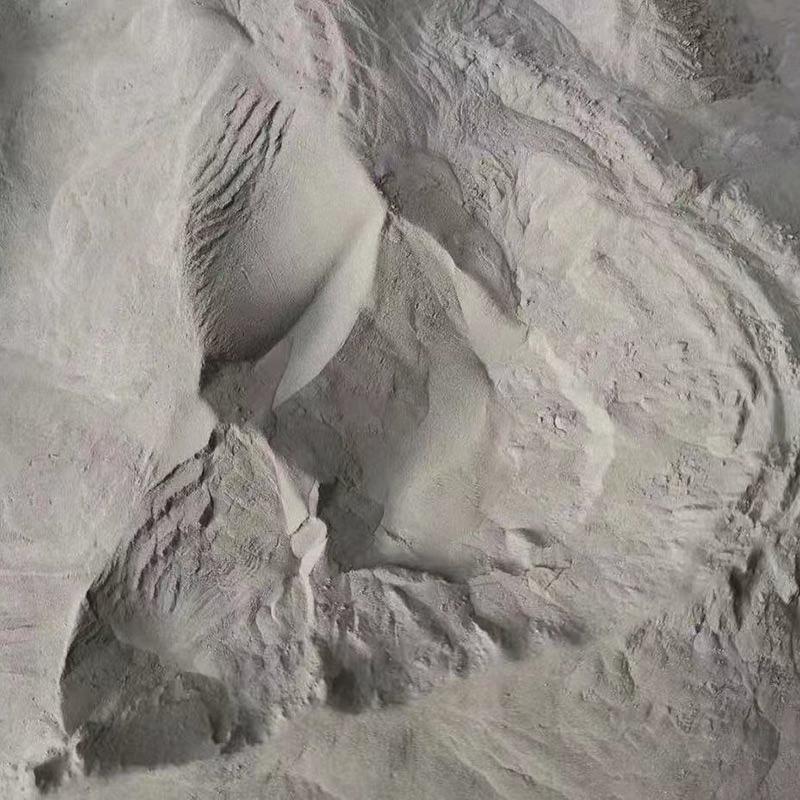

Ntxiv rau qhov zoo li saum toj no, cov hmoov hlau ua los ntawm lub tshuab nqus tsev smelting high-pressure gas atomization muaj peb yam nram qab no: ntshiab hmoov, tsis tshua muaj oxygen cov ntsiab lus; siab tawm los ntawm cov hmoov zoo; siab zoo li sphericity. Cov khoom siv los yog cov khoom siv ua haujlwm ua los ntawm cov hmoov no muaj ntau yam zoo dua cov khoom siv raws li lub cev thiab tshuaj lom neeg. Cov hmoov tsim muaj xws li superalloy hmoov, thermal spray alloy hmoov, tooj liab alloy hmoov thiab stainless hlau hmoov.

1 Nqus cua atomization hmoov milling txheej txheem thiab khoom siv

1.1 Nqus cua atomization hmoov milling txheej txheem

Lub tshuab nqus tsev atomization pulverizing txoj kev yog ib hom tshiab ntawm cov txheej txheem tsim nyob rau hauv cov hlau hmoov manufacturing kev lag luam nyob rau hauv xyoo tas los. Nws muaj qhov zoo ntawm tsis yooj yim oxidation ntawm cov ntaub ntawv, ceev quenching ntawm hlau hmoov, thiab qib siab ntawm automation. Cov txheej txheem tshwj xeeb yog tias tom qab cov hlau nplaum (hlau) yog yaj thiab ua kom zoo rau hauv qhov cub induction, cov kua hlau molten yog nchuav rau hauv cov thermal rwb thaiv tsev slump, thiab nkag mus rau hauv cov lus qhia raj thiab lub nozzle, thiab cov yaj ntws yog atomized los ntawm high- siab gas flow. Lub atomized hlau hmoov solidifies thiab settles nyob rau hauv lub atomization ntauwd, thiab ntog mus rau hauv lub hmoov sau tank.

Cov khoom siv atomizing, atomizing ultrasonic thiab hlau ua kua dej yog peb yam yooj yim ntawm cov txheej txheem roj atomization. Hauv cov khoom siv atomization, cov tshuaj atomizing ultrasonic nrawm nrawm thiab cuam tshuam nrog cov kua hlau txhaj tshuaj los tsim cov dej ntws. Nyob rau hauv no ndlwg teb, molten hlau ntws yog tawg, txias thiab solidified, yog li tau txais hmoov nrog tej yam ntxwv. Cov khoom siv atomization tsis muaj xws li nozzle qauv, catheter qauv, catheter txoj hauj lwm, thiab lwm yam., atomization gas thiab nws cov txheej txheem tsis muaj xws li ultrasonic zog, cua inlet siab, huab cua tshaj tawm, thiab lwm yam., thiab hlau kua ntws thiab nws cov txheej txheem tsis muaj xws li cov hlau ua kua. Cov khoom, superheat, kua ntws txoj kab uas hla, thiab lwm yam. Ultrasonic atomization ua tiav lub hom phiaj ntawm kev kho cov hmoov particle loj, particle loj tis thiab microstructure los ntawm kev kho ntau yam tsis thiab lawv. kev sib koom tes.

1.2 Nqus cua atomization pulverizing khoom

Lub tshuab nqus tsev atomization pulverizing tam sim no feem ntau suav nrog cov khoom siv txawv teb chaws thiab cov khoom siv hauv tsev. Cov cuab yeej tsim tawm txawv teb chaws muaj kev ruaj ntseg siab thiab kev tswj xyuas siab, tab sis cov cuab yeej siv tau siab, thiab kev kho thiab kho tus nqi siab. Cov cuab yeej siv hauv tsev yog tus nqi qis, tus nqi kho mob tsawg, thiab kev saib xyuas yooj yim. Txawm li cas los xij, cov tuam txhab khoom siv hauv tsev feem ntau tsis paub txog cov thev naus laus zis tseem ceeb ntawm cov cuab yeej xws li atomizing nozzles thiab cov txheej txheem atomization. Tam sim no, cov koom haum tshawb fawb txawv teb chaws thiab cov chaw tsim khoom lag luam khaws cov thev naus laus zis nruj me ntsis tsis pub lwm tus paub, thiab cov txheej txheem tshwj xeeb thiab kev lag luam tsis tuaj yeem tau txais los ntawm cov ntaub ntawv tseem ceeb thiab patents. Qhov no ua rau cov txiaj ntsig zoo ntawm cov hmoov nplej siab dhau los ua kev lag luam, uas kuj yog qhov laj thawj tseem ceeb vim li cas kuv lub teb chaws tsis tuaj yeem tsim cov hmoov zoo txawm tias muaj ntau cov hmoov aerosol ntau lawm thiab cov kev tshawb fawb tshawb fawb.

Cov qauv ntawm ultrasonic atomization pulverizing ntaus ntawv muaj cov nram qab no: nruab nrab zaus induction melting rauv, tuav rauv, atomization system, atomization tank, plua plav sau system, ultrasonic mov system, dej txias system, tswj system, thiab lwm yam.

Tam sim no, ntau yam kev tshawb fawb ntawm aerosolization feem ntau tsom rau ob yam. Ntawm qhov tod tes, cov kev ntsuas ntawm cov qauv nozzle thiab cov yam ntxwv ntawm lub dav hlau ntws tau kawm. Lub hom phiaj yog kom tau txais kev sib raug zoo ntawm lub tshav dav hlau thiab cov qauv nozzle, kom lub ultrasonic nce mus txog qhov ceev ntawm lub qhov hluav taws xob nozzle thaum lub ultrasonic ndlwg tus nqi me me, thiab muab lub hauv paus theoretical rau kev tsim thiab ua ntawm lub nozzle. Ntawm qhov tod tes, kev sib raug zoo ntawm cov txheej txheem atomization tsis tau kawm thiab cov hmoov hmoov tau kawm. Nws lub hom phiaj los kawm txog cov txiaj ntsig ntawm cov txheej txheem atomization tsis nyob ntawm cov khoom siv hmoov thiab atomization efficiency ntawm lub hauv paus tshwj xeeb rau kev ua kom zoo thiab coj cov hmoov ntau lawm. Hauv ib lo lus, kev txhim kho cov khoom tsim tau zoo ntawm cov hmoov zoo thiab txo cov roj noj ua rau txoj kev loj hlob ntawm ultrasonic atomization tshuab.

1.2.1 Ntau hom nozzles rau ultrasonic atomization

Cov roj atomizing ua rau kom ceev thiab lub zog los ntawm lub nozzle, yog li ua kom cov kua hlau ua kom zoo thiab npaj cov hmoov uas ua tau raws li qhov yuav tsum tau ua. Lub nozzle tswj qhov ntws thiab ntws qauv ntawm qhov nruab nrab atomized, thiab ua lub luag haujlwm tseem ceeb hauv qib ntawm atomization efficiency thiab kev ruaj ntseg ntawm cov txheej txheem atomization, thiab yog lub tshuab tseem ceeb ntawm ultrasonic atomization. Nyob rau hauv cov txheej txheem roj atomization thaum ntxov, feem ntau siv cov qauv dawb-lub caij nplooj zeeg nozzle. Cov nozzle no yooj yim hauv kev tsim, tsis yooj yim rau kev thaiv, thiab cov txheej txheem tswj tau yooj yim, tab sis nws qhov kev ua haujlwm atomization tsis siab, thiab nws tsuas yog tsim rau cov hmoov nplej nrog particle loj ntawm 50-300 μm. Txhawm rau txhim kho kev ua haujlwm ntawm atomization, txwv tsis pub cov nozzles lossis nruj nreem txuas atomizing nozzles tau tsim tom qab. Lub kaw ntom nti los yog txwv tsis pub ua kom luv lub dav hlau ya dav hlau thiab txo cov kinetic zog poob hauv cov txheej txheem roj, yog li ua kom nrawm thiab ceev ntawm cov roj ntws cuam tshuam nrog cov hlau, thiab ua rau cov hmoov zoo ntxiv.

1.2.1.1 Circumferential Qhov Nozzle

Kev kub siab ultrasonic nkag mus rau lub nozzle tangentially. Tom qab ntawd nws yog ejected ntawm kev kub ceev los ua ib tug vortex

Txhawm rau tsim 3D Printing, Tuam Tshoj xav tau los tsim nws tus kheej Innovation Chain thiab Industrial Chain

Nyob rau hauv ob xyoos dhau los, txoj kev loj hlob ntawm cov additive manufacturing kev lag luam tau nce mus rau lub teb chaws lub tswv yim theem. Cov ntaub ntawv xws li "Made in China 2025" thiab "National Additive Manufacturing Industry Development Action Plan (2015-2016)" tau raug tso tawm. Kev lag luam additive manufacturing tau tsim sai heev. Qhov tseem ceeb ntawm kev lag luam thev naus laus zis yog booming. Txawm hais tias qhov no, vim tias kev lag luam tsim khoom yog nyob rau theem pib ntawm txoj kev loj hlob, nws tseem qhia tau hais tias cov yam ntxwv ntawm cov nplai qis. Cov kws tshaj lij lees paub tias cov khoom siv txawv teb chaws tam sim no ua rau "tawm tsam" hauv Suav lag luam. Siv cov cuab yeej luam ntawv hlau ua piv txwv, cov teb chaws txawv teb chaws siv kev muag khoom ntawm cov khoom siv, software, khoom siv thiab cov txheej txheem. kuv lub teb chaws yuav tsum ceev cov kev tshawb fawb thiab kev loj hlob ntawm core technologies thiab thawj technologies, thiab tsim nws tus kheej innovation saw thiab industrial saw.

Kev ua lag luam zeem muag yog qhov zoo

Raws li McKinsey tsab ntawv ceeb toom, kev tsim khoom ntxiv yog qib cuaj ntawm 12 thev naus laus zis uas muaj kev cuam tshuam rau tib neeg lub neej, ua ntej ntawm cov khoom siv tshiab thiab cov pa roj carbon monoxide, thiab nws tau kwv yees tias los ntawm 2030 kev tsim khoom ntxiv yuav ncav cuag Kev lag luam loj ntawm ib ncig ntawm $ 1 trillion. Hauv 2015, tsab ntawv tshaj tawm tau hloov cov txheej txheem no mus rau tom ntej, sib cav tias los ntawm 2020, uas yog, peb xyoos tom qab, lub ntiaj teb additive manufacturing lag luam loj tuaj yeem ncav cuag qhov txiaj ntsig ntawm 550 billion US dollars. McKinsey tsab ntawv ceeb toom tsis yog qhov xav tau.

Lu Bingheng, kws tshaj lij ntawm Suav Academy ntawm Engineering thiab tus thawj coj ntawm National Additive Manufacturing Innovation Center, tau siv "plaub thiab ib nrab" los piav qhia txog kev lag luam yav tom ntej ntawm kev tsim khoom ntxiv.

Ntau tshaj li ib nrab ntawm cov khoom muaj nqis yav tom ntej yog tsim;

Ntau tshaj li ib nrab ntawm cov khoom tsim tau customized;

Ntau tshaj li ib nrab ntawm cov qauv tsim yog cov neeg coob coob;

Ntau tshaj li ib nrab ntawm kev tsim kho tshiab yog tsim los ntawm cov neeg tsim khoom.

Additive manufacturing yog ib qho kev cuam tshuam technology uas ua rau txoj kev loj hlob ntawm kev tsim khoom. Nws yog ib lub tshuab tsim nyog los txhawb kev tsim kho tshiab, tsim khoom tsim kho, tsim kev tsim kho tshiab thiab kev tsim khoom coob coob. "Qhov tseem ceeb tshaj, kev tsim khoom ntxiv yog ib qho cuab yeej tsis tshua muaj kev sib txuas nrog lub ntiaj teb hauv kuv lub teb chaws. Tam sim no, Tuam Tshoj txoj kev tshawb fawb ntawm 3D luam ntawv yog nyob rau hauv pem hauv ntej ntawm lub ntiaj teb no."

Lu Bingheng tau hais tias tam sim no, cia siab rau qhov loj-scale 3D luam ntawv hlau atomization thiab milling khoom tsim los ntawm kuv lub teb chaws nws tus kheej, Tuam Tshoj yog nyob rau hauv lub thoob ntiaj teb txoj hauj lwm nyob rau hauv daim ntawv thov ntawm loj-scale load-bearing qhov chaw ntawm aircraft, thiab ua raws li ib tug kev cai lij choj. pab neeg ua haujlwm pabcuam thawj zaug hauv kev tshawb fawb thiab kev tsim cov tub rog dav hlau thiab cov dav hlau loj. Tsis tas li ntawd, titanium alloy loj-teev yam ntxwv qhov chaw tau siv nyob rau hauv kev tshawb fawb thiab kev loj hlob ntawm aircraft tsaws iav thiab C919.

Nyob rau hauv cov nqe lus ntawm daim ntawv thov, kuv lub teb chaws lub peev xwm ntawm industrial-qib khoom nyob rau hauv qeb plaub nyob rau hauv lub ntiaj teb no, tab sis cov khoom lag luam rau hlau luam ntawv tseem tsis muaj zog, thiab feem ntau cia siab rau imports. Txawm li cas los xij, raws li Academician Lu Bingheng, tag nrho lub hom phiaj ntawm Tuam Tshoj txoj kev tsim khoom ntxiv yog kom ua tiav lub ntiaj teb thib ob loj tshaj plaws tsim muaj peev xwm thiab thib peb cov khoom siv loj tshaj plaws thiab muag khoom hauv ntiaj teb hauv 5 xyoos; thiab lub ntiaj teb thib ob loj tshaj plaws ntsia muaj peev xwm, cov khoom siv tseem ceeb thiab cov thev naus laus zis qub, thiab cov khoom muag hauv 10 xyoo. Ua tiav "Ua hauv Tuam Tshoj 2025" hauv 2035.

Kev tsim kho kev lag luam nrawm nrawm

Cov ntaub ntawv qhia tau hais tias qhov nruab nrab txoj kev loj hlob ntawm kev lag luam loj ntawm kev tsim khoom ntxiv hauv peb lub xyoos dhau los. Txoj kev loj hlob ntawm qhov kev lag luam no hauv Suav teb yog siab dua qhov nruab nrab hauv ntiaj teb.

Kos npe: feem ntau yog hais txog qhov ua tau los tswj qee qhov kev cai hauv tsev kawm ntawv

Cov paib, xws li: paj thiab nyom cov paib, tsis muaj cov paib nce toj, thiab lwm yam. Kev poob qis, tab sis nyob rau hauv kev pabcuam, qhov kev loj hlob sai heev vim yog kev txhim kho ntawm cov neeg siv khoom paub. "Tshwj xeeb hauv kev tsim khoom thiab kev tsim khoom, peb qhov kev txiav txim ntim tau nce ob npaug." Weinan 3D Printing Industry Cultivation Base hauv Shaanxi Province, nrog kev txhawb nqa los ntawm tsoomfwv hauv nroog, tau hloov pauv qhov zoo ntawm 3D luam ntawv thev naus laus zis rau hauv kev lag luam zoo thiab txhawb kev txhim kho thiab hloov pauv ntawm kev lag luam ib txwm muaj. Ib qho xwm txheej ntawm kev paub txog kev txhim kho pawg.

Kev tsom mus rau lub tswv yim ntawm kev lag luam incubation ntawm "3D printing +", nws tsis yog tsuas yog los tsim kev lag luam 3D luam ntawv, tab sis tsom mus rau kev tsim cov khoom siv 3D luam ntawv, kev tshawb fawb thiab kev loj hlob thiab kev tsim cov 3D luam ntawv hlau cov ntaub ntawv, thiab kev cob qhia. ntawm 3D luam ntawv daim ntawv thov-oriented txuj ci. Rooted nyob rau hauv lub zos ua industries, tsom rau kev siv ntawm 3D luam ntawv industrialization ua qauv qhia daim ntaub ntawv, accelerating kev koom ua ke ntawm 3D printing nrog ib txwm industries, thiab siv ib tug series ntawm 3D printing + industrial qauv xws li 3D printing + aviation, tsheb, kab lis kev cai thiab muaj tswv yim, casting, kev kawm, thiab lwm yam., nrog kev pab los ntawm 3D printing Qhov zoo ntawm cov tshuab luam ntawv, daws cov kev nyuaj siab thiab mob cov ntsiab lus ntawm tsoos industries, transform thiab upgrade ib txwm industries, thiab qhia thiab incubate ntau yam me me thiab medium-qhov loj me kev lag luam technology.

Raws li kev txheeb cais, txij li lub Tsib Hlis 2017, tus naj npawb ntawm cov lag luam tau mus txog 61, thiab ntau dua 50 qhov haujlwm xws li 3D pwm, 3D, 3D kev lag luam tshuab, 3D cov ntaub ntawv, thiab 3D kab lis kev cai thiab cov phiaj xwm muaj tswv yim tau khaws tseg, uas xav kom yuav tsum tau ua. Nws cia siab tias thaum kawg ntawm lub xyoo, tus naj npawb ntawm cov lag luam yuav tshaj 100.

Activating lub innovation saw thiab industrial saw

Txawm hais tias qhov kev loj hlob sai ntawm kuv lub teb chaws kev lag luam additive manufacturing kev lag luam, kev lag luam tseem nyob rau theem pib ntawm txoj kev loj hlob thiab tseem muaj cov yam ntxwv ntawm cov nplai qis. Txawm li cas los xij, qhov tsis muaj kev paub txog thev naus laus zis, kev siv nyiaj siab, thiab daim ntawv thov nqaim tau ua rau kev lag luam tag nrho nyob rau hauv lub xeev ntawm "me me, tawg thiab tsis muaj zog". Txawm hais tias muaj ntau lub tuam txhab tau pib taug kev hauv thaj chaw ntawm kev tsim khoom ntxiv, tsis muaj cov tuam txhab ua lag luam uas tau tsav, qhov ntsuas ntawm kev lag luam me me. Tus kws tshaj lij Lu Bingheng tau hais ncaj qha tias yog ib qho ntawm cov thev naus laus zis tseem ceeb ntawm kev hloov pauv kev lag luam yav tom ntej, kev tsim cov khoom siv ntxiv yuav tsum tau nrawm dua, vim tias 3D tshuab luam ntawv yog nyob rau lub sijhawm ntawm kev siv tshuab, lub sijhawm pib ntawm kev lag luam, thiab lub sijhawm "staking" ntawm cov lag luam. Qhov kev xav tau ntawm kev lag luam loj tuaj yeem tsav txoj kev loj hlob ntawm kev siv tshuab thiab cov cuab yeej siv, uas yuav tsum tau tiv thaiv thiab siv tag nrho los coj thiab txhawb peb cov khoom tsim khoom.

Tam sim no cov cuab yeej tuaj txawv teb chaws yog aggressively "sib ntaus" hauv Suav lag luam. Rau cov khoom siv hlau luam ntawv, cov teb chaws txawv teb chaws siv bundled muag khoom, software, khoom siv, thiab cov txheej txheem. Cov tuam txhab suav teb yuav tsum tsim cov thev naus laus zis tseem ceeb thiab cov thev naus laus zis qub los tsim lawv tus kheej kev tsim kho tshiab thiab kev lag luam chains.

Kev lag luam sab hauv tau hais tias tam sim no kev lag luam hauv tsev 3D luam ntawv, qib ntawm kev tshawb fawb thiab kev tsim kho tshuab tau siv tag nrho rau kev lag luam, thiab ntau yam kev ua tiav tsuas yog nyob rau hauv chav kuaj. Cov laj thawj tseem ceeb ntawm qhov teeb meem no yog: ua ntej, vim muaj ntau yam qauv, kev nkag mus rau Cov kev tsim nyog tsis zoo tag nrho, thiab muaj qhov tsis pom kev rau kev nkag; Thib ob, cov tsev kawm tshawb fawb thiab cov tuam txhab lag luam tsis muaj qhov cuam tshuam loj, lawv nyob hauv lub xeev ntawm kev sib ntaus sib tua ib leeg, lawv tsis muaj cai hais lus hauv kev lag luam kev sib tham, thiab lawv muaj qhov tsis zoo; Kev lag luam tshiab tsis to taub, thiab muaj kev sib tw lossis kev nkag siab yuam kev, ua rau qeeb qeeb ntawm kev siv tshuab.

Txoj Kev Loj Hlob Ntawm Cov Khoom Siv Atomization Pulverizing Yav Tom Ntej

Tseem muaj ntau qhov tsis txaus ntseeg hauv kev nkag siab ntawm 3D tshuab luam ntawv hauv txhua yam ntawm Tuam Tshoj txoj kev lag luam tsim khoom. Judging los ntawm qhov tseeb txoj kev loj hlob qhov teeb meem, txog tam sim no 3D luam ntawv tsis tau tiav mature industrialization, los ntawm cov khoom mus rau cov khoom mus rau cov kev pab cuam tseem nyob rau hauv lub "advanced khoom ua si" theem. Txawm li cas los xij, los ntawm tsoomfwv mus rau cov tuam txhab lag luam hauv Suav teb, kev txhim kho kev cia siab ntawm 3D luam ntawv thev naus laus zis feem ntau tau lees paub, thiab tsoomfwv thiab tib neeg feem ntau them nyiaj rau qhov cuam tshuam rau yav tom ntej 3D luam ntawv hlau atomization pulverizing cov cuab yeej siv tshuab ntawm kuv lub teb chaws cov khoom lag luam uas twb muaj lawm, kev lag luam, thiab tsim qauv.

Raws li cov ntaub ntawv tshawb fawb, tam sim no, kuv lub teb chaws qhov kev thov rau 3D luam ntawv thev naus laus zis tsis yog tsom rau cov cuab yeej siv, tab sis tau xav txog ntau yam ntawm 3D luam ntawv consumables thiab qhov kev thov rau lub koom haum ua cov kev pabcuam. Cov neeg siv khoom lag luam yog lub zog tseem ceeb hauv kev yuav khoom 3D luam ntawv hauv kuv lub tebchaws. Cov khoom siv uas lawv yuav yog tsuas yog siv hauv aviation, aerospace, cov khoom siv hluav taws xob, kev thauj mus los, kev tsim, kev coj noj coj ua thiab lwm yam kev lag luam. Tam sim no, lub peev xwm nruab ntawm 3D tshuab luam ntawv hauv Suav lag luam yog li 500, thiab kev loj hlob txhua xyoo yog li 60%. Txawm li cas los xij, kev lag luam tam sim no tsuas yog kwv yees li 100 lab yuan ib xyoo. Lub peev xwm thov rau R & D thiab tsim cov ntaub ntawv 3D luam ntawv tau mus txog ze li ntawm 1 billion yuan ib xyoos twg. Nrog rau qhov nrov thiab kev nce qib ntawm cov cuab yeej siv tshuab, qhov ntsuas yuav loj hlob sai. Nyob rau tib lub sijhawm, 3D luam ntawv ntsig txog kev pabcuam kev ua haujlwm yog nrov heev, thiab ntau tus neeg ua haujlwm 3D luam ntawv Lub tuam txhab cov cuab yeej siv tau zoo heev hauv cov txheej txheem laser sintering thiab cov khoom siv, thiab tuaj yeem muab kev pabcuam sab nraud. Txij li thaum tus nqi ntawm ib qho khoom siv feem ntau yog ntau tshaj 5 lab yuan, qhov kev lees paub ntawm kev ua lag luam tsis siab, tab sis lub koom haum ua cov kev pabcuam yog nrov heev.

Feem ntau ntawm cov ntaub ntawv siv nyob rau hauv kuv lub teb chaws 3D luam ntawv hlau atomization pulverizing khoom yog muab ncaj qha los ntawm prototyping sai manufacturers, thiab cov neeg thib peb ntawm cov khoom siv tseem tsis tau muab coj los siv, uas ua rau cov khoom kim heev. Nyob rau tib lub sijhawm, tsis muaj kev tshawb fawb txog kev npaj hmoov rau 3D luam ntawv hauv Suav teb, thiab muaj cov kev cai nruj me ntsis ntawm particle loj faib thiab cov ntsiab lus oxygen. Qee chav nyob siv cov tshuaj tsuag cov pa siv xwb, uas muaj ntau yam siv tsis tau.

Kev txhim kho thiab tsim cov khoom siv ntau yam yog tus yuam sij rau kev txhim kho thev naus laus zis. Kev daws cov teeb meem kev ua tau zoo thiab cov nqi ntawm cov ntaub ntawv yuav zoo dua los txhawb kev txhim kho sai prototyping thev naus laus zis hauv Suav teb. Tam sim no, feem ntau ntawm cov ntaub ntawv siv nyob rau hauv kuv lub teb chaws 3D luam ntawv sai prototyping tshuab yuav tsum tau imported los ntawm txawv teb chaws, los yog cov khoom manufacturers tau nqis peev ntau lub zog thiab nyiaj txiag los tsim lawv, uas yog kim, ua rau cov nqi ntau lawm, thaum. cov khoom siv hauv tsev siv nyob rau hauv lub tshuab no muaj lub zog tsawg thiab qhov tseeb. . Localization ntawm 3D luam ntawv cov ntaub ntawv yog qhov tseem ceeb.

Titanium thiab titanium alloy hmoov los yog npib tsib xee-raws li thiab cobalt-based superalloy hmoov uas tsis tshua muaj oxygen cov ntsiab lus, nplua particle loj thiab siab sphericity yuav tsum tau. Cov hmoov particle loj yog feem ntau -500 mesh, cov ntsiab lus oxygen yuav tsum qis dua 0.1%, thiab cov particle loj yog uniform Tam sim no, high-end alloy hmoov thiab cov cuab yeej tsim khoom tseem tsuas yog cia siab rau imports. Hauv cov teb chaws txawv teb chaws, cov khoom siv raw thiab cov khoom siv feem ntau tau ntim thiab muag kom tau txais txiaj ntsig ntau. Noj cov hmoov nickel raws li piv txwv, tus nqi ntawm cov khoom siv raw yog kwv yees li 200 yuan / kg, tus nqi ntawm cov khoom siv hauv tsev feem ntau yog 300-400 yuan / kg, thiab tus nqi ntawm cov hmoov tuaj txawv teb chaws feem ntau ntau dua 800 yuan / kg.

Piv txwv li, kev cuam tshuam thiab kev hloov pauv ntawm cov hmoov muaj pes tsawg leeg, suav nrog thiab lub cev muaj zog ntawm cov cuab yeej muaj feem xyuam ntawm 3D luam ntawv hlau atomization hmoov milling khoom. Yog li ntawd, nyob rau hauv qhov kev pom ntawm kev siv cov ntsiab lus ntawm cov pa oxygen tsawg thiab cov hmoov zoo me me, nws tseem yuav tsum tau ua cov haujlwm tshawb fawb xws li kev tsim qauv ntawm titanium thiab titanium alloy hmoov, roj atomization hmoov milling tshuab ntawm cov hmoov me me hmoov, thiab kev cuam tshuam ntawm hmoov yam ntxwv ntawm cov khoom ua tau zoo. Vim muaj kev txwv ntawm kev siv tshuab milling hauv Suav teb, nws yog ib qho nyuaj rau kev npaj cov hmoov nplej nplua nuj nyob rau tam sim no, cov hmoov nplej tau qis, thiab cov ntsiab lus ntawm oxygen thiab lwm yam impurities yog siab. Thaum lub sij hawm siv cov txheej txheem, cov hmoov melting lub xeev yog nquag mus rau unevenness, ua rau cov ntsiab lus siab ntawm oxide inclusions thiab denser khoom nyob rau hauv cov khoom. Cov teeb meem tseem ceeb ntawm cov hmoov hlau hauv tsev yog nyob rau hauv cov khoom zoo thiab kev ruaj ntseg batch, xws li: ① ruaj khov ntawm cov khoom siv hmoov (tus naj npawb ntawm cov khoom sib xyaw, cov khoom sib xws); ② hmoov lub cev ruaj khov ntawm kev ua tau zoo (particle loj faib, hmoov morphology, fluidity, xoob ratio, thiab lwm yam); ③ teeb meem ntawm yield (tsawg tawm los ntawm hmoov nyob rau hauv nqaim particle loj seem), thiab lwm yam.

Khoom Qhia

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur