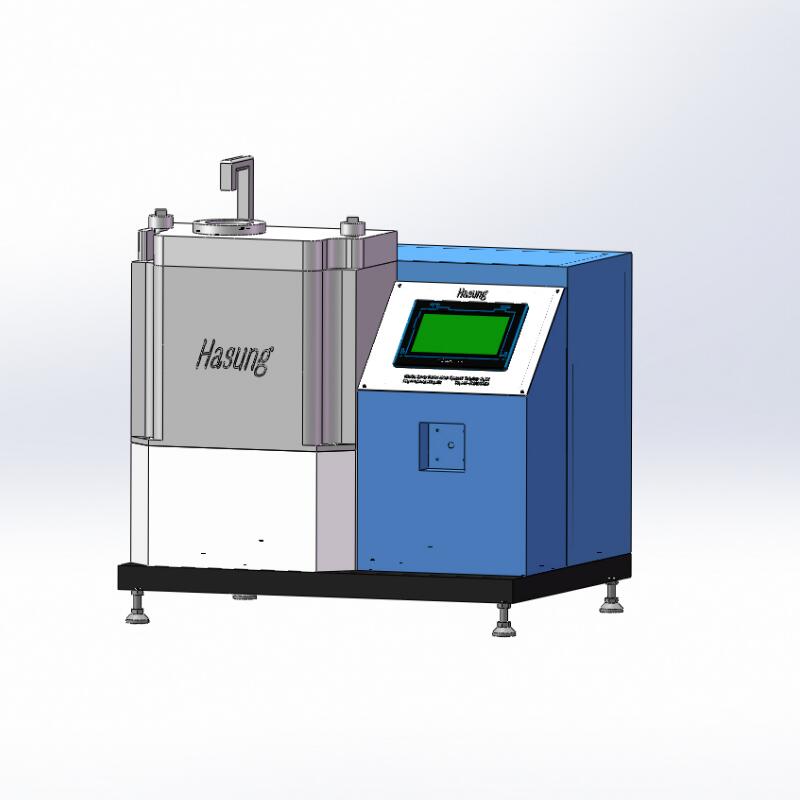

Vacuum Pressure Casting Machine

HASUNG casting tshuab yog tsim rau yaj thiab cam khwb cia hlau ntawm siab melting kub. Raws li tus qauv, lawv tuaj yeem nrum thiab yaj kub, Karat kub, nyiaj, tooj liab, alloy nrog TVC, VPC, VC series, kuj steel, platinum, palladium nrog MC series.

Lub tswv yim tseem ceeb ntawm HASUNG lub tshuab nqus tsev siab casting yog kaw lub hau thiab pib cua sov thaum lub tshuab tau ntim nrog cov khoom siv hlau.

Qhov kub yuav raug xaiv los ntawm tes.

Cov khoom yog molten nyob rau hauv kev tiv thaiv roj (argon/nitrogen) kom tsis txhob oxidation. Cov txheej txheem melting tuaj yeem pom tau yooj yim los ntawm lub qhov rais saib. Lub crucible yog muab tso rau hauv nruab nrab nyob rau hauv lub Upper ib feem ntawm cov huab cua nruj kaw aluminium chamber nyob rau hauv lub hauv paus ntawm lub induction spool. Nyob rau hauv lub meantime, lub hwj nrog lub rhuab mus casting daim ntawv yog muab tso rau hauv qis ib feem ntawm stainless hlau nqus tsev chamber. Lub tshuab nqus tsev yog tilted thiab docked nyob rau hauv lub crucible. Rau cov txheej txheem casting lub crucible yog teem nyob rau hauv siab thiab lub hwj nyob rau hauv lub nqus tsev vacuum. Qhov sib txawv ntawm qhov siab ua rau cov kua hlau ua rau qhov zoo tshaj plaws ramification ntawm daim ntawv. Lub siab yuav tsum tau teem los ntawm 0.1 Mpa rau 0.3 Mpa.

Lub tshuab nqus tsev zam tsis muaj npuas thiab porosity.

Tom qab ntawd lub tshuab nqus tsev yog qhib thiab lub hwj tuaj yeem muab tshem tawm.

Lub TVC, VPC, VC series tshuab yog nruab nrog lub tshuab nqa nqa uas thawb lub khob rau ntawm lub caster. Qhov no simplifies qhov kev tshem tawm ntawm lub hwj.

MC series tshuab yog tilting lub tshuab nqus tsev casting hom, nrog 90 degrees tig tshwj xeeb uas tsim los rau kub kub hlau casting. Nws tau hloov centrifugal casting.

-

VCT Series Nqus Siab Casting Tshuab nrog PLC kov npo

NEXT lub tshuab nqus tsev siab los ntawm Hasung yog koj lub tshuab txuas ntxiv los tsim kom zoo.

1 Txhawb lub hwj nrog flange thiab lub hwj tsis muaj flange

2. Zoo melting ceev, txuag zog

3. Inert Gas - nrog cov khoom ntim zoo

4. Precise gauge nrog txhim kho lub siab

5. Yooj yim tswj

6. Lub sijhawm ua haujlwm siab

7. Kev kuaj tus kheej - Taiwan Weinview PLC kov vaj huam sib luag nws pib-tuning

8. Yooj yim rau kev khiav lag luam, ib lub botton kom tiav tag nrho cov txheej txheem casting9. Tom qab hom tsis muaj oxidation

10. Hloov pauv kub rau kub poob

11. Lub tshuab nqus tsev siab, argon siab, kub, lub sij hawm nchuav, lub sij hawm siab, lub sij hawm nqus.

-

VCTV Series Jewelry Vacuum Pressure Casting Tshuab nrog Vibration System

NEXT lub tshuab nqus tsev siab los ntawm Hasung yog koj lub tshuab txuas ntxiv los tsim kom zoo.

1. Ob hom rau lub hwj nrog flange thiab flask tsis muaj flange

2. Vibration system rau nplua casting

3. Kev sib xyaw ntxiv rau kev sib cais zoo ntawm kub

4. Zoo melting ceev, txuag zog

5. Inert Gas - nrog cov khoom ntim zoo

6. Precise gauge nrog txhim kho lub siab

7. Yooj yim tswj

8. Lub sijhawm ua haujlwm siab

9. Kev kuaj tus kheej - Nyiv Mitsubishi PLC kov vaj huam sib luag auto-tuning

10. Yooj yim rau kev khiav lag luam, ib lub botton kom tiav tag nrho cov txheej txheem casting11. Tom qab hom tsis muaj oxidation

12. Cov cua sov hloov pauv rau kub poob

13. Lub tshuab nqus tsev siab, argon siab, kub, lub sij hawm nchuav, lub sij hawm siab, lub sij hawm nqus, lub sij hawm vibration, vibration tuav lub sij hawm tuaj yeem teem tau, Program rau lub hwj nrog flange, qhov kev pab cuam rau lub hwj tsis muaj flange, ob qho tib si muaj, nws pib hom thiab phau ntawv hom muaj.

-

TVC Series Induction Nqus Plua Plav Casting Tshuab rau Kub Silver Copper

Puv Tsis Siv Neeg Lub Tshuab Nqus Siab Casting Tshuab

Cov cuab yeej tshiab los txhim kho cov txiaj ntsig casting

Hasung Casting System

1. Kaw lub hau yuav, txhua yam yog automaticlly kev khiav hauj lwm rau casting feem ntau txhim kho cov khoom ntws thiab pwm filling

2.Castings nthuav tawm ntau dua thiab zoo ib yam

3.Porosity tau txo qis

4. Nrog Max. 4 bars casting siab.

5. SBS txiav tshuab tsis siv cov gaskets, txuag nqi.

6.Castings muaj kev ntxhov siab ntau dua thiab elasticity, ua rau lawv yooj yim dua rau kev ua haujlwm ntxiv.

7. Ib qho yooj yim kov ua haujlwm nrog cov txiaj ntsig parameter screen

8. 100 cov kev pab cuam muaj.

-

VPC Series Nqus Siab Casting Tshuab rau Jewellery

Siab tshaj lub tshuab nqus tsev Casting

VCT yog ib tsev neeg ntawm siab tshaj lub tshuab nqus tsev casting tshuab tsim los ua kom tau raws li qhov xav tau hnyav dua hauv kev ploj tuag casting ntau lawm ntawm kub, K-kub, tooj liab, bronze, alloys. Lawv feem ntau siv nyob rau hauv kev twb kev txuas mus rau ib tug 3d tshuab luam ntawv rau ncaj qha casting kom tau cov thawj hlau qhov chaw ntawm complex khoom.

Cov tsev neeg ntawm cov tshuab no ua haujlwm nrog lub tswv yim tshiab, hloov pauv ob chav chamber. Qhov kev tsim kho tshiab no muab ntau qhov zoo dua piv nrog cov tsoos ib leeg chamber suction system tam sim no muaj nyob hauv khw.

Nyob rau hauv VCT, melting chamber thiab flask chamber yog tag nrho indipendent: thaum casting, lub tshuab tuaj yeem tswj cov hlau txhaj rau hauv pwm los ntawm kev siv lub siab sib txawv thaum lub sij hawm nchuav. Qhov no yields rau kev txhaj tshuaj sai dua piv rau qhov yooj yim lub ntiajteb txawj nqus pouring nrog cov txiaj ntsig los nrum cov khoom ntawm qhov kub thiab txias. Qhov no yuav ua rau kom zoo dua nto tiav thiab txo qis shrinkage ntawm cov khoom cam khwb cia.Lub voj voog casting tsuas siv ob peb feeb xwb thiab, thaum lub khob dej dhau los txias hauv cov roj tiv thaiv kom tsis muaj oxidation, tus nqi tom ntej tuaj yeem thauj mus rau hauv crucible thiab melted, yog li sib tshooj ob lub voj voog tsis muaj sij hawm pov tseg.

Lub tshuab yog siab tsis siv neeg, featuring PC raws li kev saib xyuas cov txheej txheem tsis tau txais thiab kev tswj cov ntaub ntawv ntau lawm, nrog kev kho kom yooj yim ntawm cov kev pab cuam casting tsim rau ntau hom hlau.

Lub tshuab revolutionary no yog cov synthesis ntawm feem ntau advanced engineering thiab xyoo ntawm kev paub nyob rau hauv casting uas tsuas Hasung yuav coj nyob rau hauv koj lub Hoobkas.

-

Hasung T2 Jewelry Vacuum Pressure Casting Tshuab

TSEEM CEEB lub tshuab nqus tsev siab casting tshuab los ntawm Hasung yog koj lub tshuab txuas ntxiv los tsim kom zoo.

T2 qhov zoo:

1. Tom qab hom tsis muaj oxidation

2. Cov cua sov hloov pauv rau kub poob

3. Kev sib xyaw ntxiv rau kev sib cais zoo ntawm kub

4. Zoo melting ceev

5. De-Gas - nrog cov khoom ntim zoo rau cov hlau

6. Precise ob-needle gauge nrog txhim kho lub siab

7. Yooj yim rau khaws cia thaum casting

8. Lub sijhawm ua haujlwm siab

9. Kev kuaj tus kheej - PID pib-tuning

10. Nco txog parameter rau qhov zoo tshaj plaws casting

11. Casting System Nqus siab casting system - max. siab 0.3MPa nrog cov roj tank sab hauv

12. Hloov Gas Ib qho roj (Argon)

13. Program Memory 100 nco

14. Tswj tshwj xeeb tsim microprocessor tswj. Kev tswj kub los ntawm PID nrog qhov tseeb ntawm +/-1 degrees centigrade.

15. Cua sov induction cua sov (nrog tshwj xeeb tsim hlau stirring muaj nuj nqi). -

Mini Vacuum Pressure Casting Tshuab rau Platinum Palladium Steel Kub Nyiaj

Hasung Precious Metals SVC / MC Khoom zoo

SVC / MC series yog cov cav tov ntau yam zoo heev uas tsim nyog rau ntau yam kev siv rau cov hlau castings - thiab ntau txoj kev xaiv uas tau txiav txim siab tsis sib haum txog tam sim no. Yog li, thaum lub sij hawm MC series yog Ameslikas tsim los ua ib tug high-temperature casting tshuab rau casting steel, palladium, platinum thiab lwm yam. (max. 2,100 ° C), loj flasks kuj ua rau nws haum rau economically tsim castings nyob rau hauv kub, nyiaj, tooj liab, steel, alloy thiab lwm yam ntaub ntawv.

Lub tshuab ua ke nrog ob chav chamber sib txawv siab nrog lub tshuab tilting. Cov txheej txheem casting yog ua tiav los ntawm rotating tag nrho melting-casting unit los ntawm 90 °. Ib qho txiaj ntsig ntawm qhov tilting system yog kev siv nyiaj txiag graphite lossis ceramic crucibles (tsis muaj qhov thiab cov hlua khi). Cov no yuav muaj lub neej ua haujlwm ntev dua. Qee cov alloys, xws li tooj liab beryllium, sai sai ua rau crucibles nrog lub qhov thiab sealing rods ua untight thiab yog li ntawd tsis siv. Vim li no, ntau tus casters tau ua tiav cov hlau no tsuas yog hauv cov tshuab qhib. Tab sis qhov no txhais tau hais tias lawv tsis tuaj yeem xaiv los txhim kho cov txheej txheem nrog overpressure lossis nqus.

-

Tilting Nqus Siab Casting Tshuab rau Platinum Palladium Kub Nyiaj Hlau

Hasung Precious Metals Equipment zoo

Cov khoom muaj xim sib xws thiab tsis muaj kev sib cais:

Lub porosity yog txo, thiab qhov ceev yog siab dua thiab tas li, txo cov kev ua haujlwm tom qab thiab txo qhov poob.

Cov khoom zoo dua fluidity thiab pwm filling, txo kev txaus siab txaus siab:

Kev vibration txhim kho cov khoom ntws, thiab cov qauv ntawm cov khoom yog compact dua. Txhim kho cov duab filling thiab txo qhov kev pheej hmoo ntawm kub tawg

Lub grain loj yog txo mus rau 50%:

Solidify nrog ib tug finer thiab ntau uniformity

Cov khoom siv zoo dua thiab ruaj khov dua:

Lub zog tensile thiab elasticity tau nce los ntawm 25%, thiab cov kev ua haujlwm tom qab tau txhim kho.

Q: Txoj Kev Nqus Casting yog dab tsi?

Kev nqis peev castings, uas feem ntau hu ua ploj-wax castings, yog cov khoom hlau uas yog tsim los ntawm kev nqis peev casting txheej txheem. Qhov no expendable pwm txheej txheem thiab cov khoom uas nws tsim yog heev nrov rau suav tsis txheeb daim ntaub ntawv nyob rau hauv ntau industries. Qhov no feem ntau yog vim qhov tseeb tias kev nqis peev casting txheej txheem ua rau nws muaj peev xwm los tsim qhov nyuaj nrog qhov tshwj xeeb saum npoo zoo thiab raug nyob rau hauv ntau yam khoom thiab ntau thiab tsawg. Txawm li cas los xij, yog tias ib feem yuav tsum muaj cov ntsiab lus tsis sib xws lossis kev txiav, cov khoom siv yog siv los ntawm fiber ntau los yog hlau, los yog huab cua entrapment yog ib qho teeb meem, ib hom peev txheej casting yog siv. Qhov peev txheej casting no tsis muaj lwm yam tshaj li lub tshuab nqus tsev casting, uas tsim lub tshuab nqus tsev castings. Lub tshuab nqus tsev casting yog dab tsi? Mus nyeem ntawv kom paub.

Vacuum Investment Castings yog dab tsi?

Nqus castings yog cov hlau qhov chaw uas yog tsim los ntawm lub tshuab nqus tsev casting txoj kev. Lawv txawv dua li cov peev txheej castings vim yog cov txheej txheem uas siv los tsim cov hlau no. Cov txheej txheem pib los ntawm kev tso ib daim ntawm plaster pwm nyob rau hauv lub tshuab nqus tsev chamber. Lub tshuab nqus tsev ces rub cov hlau molten rau hauv pwm. Thaum kawg, lub casting yog solidified nyob rau hauv ib lub qhov cub thiab cov pwm raug tshem tawm nyob rau hauv thiaj li yuav tso cov khoom zaum kawg.

Yog tias koj muaj ib qhov project uas yuav tsum tau ua kom zoo tshaj lub tshuab nqus tsev peev castings rau jewellery lossis lwm yam hlau, peb tuaj yeem muab rau koj. Ntawm no ntawm Hasung, peb siv ob lub ntiajteb txawj nqus noj thiab nqus casting txoj kev los tsim kub, nyiaj, platinum, hlau Cheebtsam uas muaj ntau yam. Peb suav tsis txheeb xyoo ntawm kev paub nyob rau hauv ob qho tib si ntawm cov txheej txheem no tau lees tias peb tuaj yeem muab cov khoom zoo tshaj plaws los yog ze ntawm cov khoom siv uas yuav tsum tau ua haujlwm me me lossis tsis ua tiav. Tau txais cov peev castings uas koj xav tau, xa raws sijhawm thiab ntawm tus nqi sib tw, los ntawm kev tiv tauj peb hnub no!

Q: Yuav ua li cas xaiv cov hniav nyiaj hniav kub?

Cov hniav nyiaj hniav kub casting yog txheej txheem ntawm kev ua cov hniav nyiaj hniav kub uas cuam tshuam nrog kev nchuav cov kua hlau alloy rau hauv pwm. Nws yog feem ntau hu ua ploj-wax casting vim hais tias cov pwm casting yog tsim siv cov qauv siv quav ciab uas yog yaj mus kom tawm hauv lub chamber hollow hauv nruab nrab ntawm cov pwm. Cov txheej txheem tau siv ntau txhiab xyoo, thiab tseem siv dav niaj hnub no los ntawm ob tus tswv craftsmen thiab tsev crafters los ua kom meej reproductions ntawm thawj cov hniav nyiaj hniav kub daim. Yog tias koj xav tsim koj tus kheej cov hniav nyiaj hniav kub siv cov txheej txheem casting, ua raws li cov kauj ruam no rau yuav ua li cas cam khwb cia hniav nyiaj hniav kub.

1. Crafting Koj Pwm

1) Carve ib daim tawv qauv siv quav ciab rau hauv koj qhov kev xav tau. Pib yooj yim rau tam sim no, vim cov pwm nyuaj nyuaj dua ua ke thaum xub thawj. Tau txais ib daim qauv siv quav ciab thiab siv rab riam, Dremel, thiab lwm yam cuab yeej xav tau los ua tus qauv ntawm koj cov hniav nyiaj hniav kub. Txawm li cas los xij koj ua tam sim no yuav yog cov duab ntawm koj cov khoom tiav.

Koj tab tom ua ib qho piv txwv ntawm koj cov hniav nyiaj hniav kub thaum kawg.

Siv ib daim ntawm cov hniav nyiaj hniav kub uas koj nyiam ua qauv yuav pab koj tsim cov khoom zoo dua thaum koj pib ua ntej.

2) Txuas 3-4 "sprues," wax xov hlau uas yuav muab cov channel rau cov quav ciab kom yaj tom qab. Siv ib co ntxiv siv quav ciab, crafts ob peb ntev, xov hlau tawm ntawm cov quav ciab thiab muab lawv mus rau tus qauv kom lawv tag nrho cov coj mus deb ntawm daim. Qhov no yooj yim dua rau kev nkag siab thaum koj pom tag nrho cov txheej txheem - qhov no siv quav ciab yuav muab npog rau hauv plaster, tom qab ntawd yaj tawm los ua qhov khoob ntawm koj cov duab. Tom qab ntawd koj sau rau hauv qhov hollow nrog nyiaj. Yog tias koj tsis ua sprues, cov wax melted tsis tuaj yeem tawm thiab ua rau thaj tsam hollow.

Rau cov khoom me me, zoo li lub nplhaib, koj tsuas yog xav tau ib lub sprue. Cov khoom loj dua, zoo li siv cov buckles, yuav xav tau txog li kaum.

Tag nrho cov sprues yuav tsum tau ntsib nyob rau tib qhov chaw. Lawv yuav tsum tau txuas nrog lub hauv paus sprue.

3) Txuas cov pwm rau lub hauv paus sprue siv me ntsis ntawm cov roj hmab melted. Cov sprues tag nrho sib ntsib ua ke, thiab koj txuas cov pwm mus rau lub hauv paus sprue qhov twg tag nrho cov sprues ntsib. Qhov no tso cai rau cov quav ciab kom yaj hauv qab ntawm lub hauv paus thiab tawm hauv pwm.

4) Muab lub hwj tso rau saum lub hauv paus sprue, kom paub tseeb tias koj muaj ib lub quarter ntiv tes nruab nrab ntawm phab ntsa ntawm lub hwj thiab tus qauv. Lub raj mis yog ib lub tog raj kheej loj uas swb rau saum lub hauv paus sprue.

2. Kev nqis peev pwm

1) Ruaj ntseg tus qauv siv quav ciab sawv ntsug rau hauv qab ntawm lub lauj kaub tais diav, siv cov khoom siv ntau dua. Cov qauv yuav tsum tau muab tso rau hauv lub hwj. Nws yog npaj rau cov hniav nyiaj hniav kub casting txheej txheem.

Nco tseg: Hauv daim vis dis aus, qhov nyiaj ntau dhau yog lwm cov nyiaj hniav kub nrog rau txoj siv hlua. Lawv tsis yog sprues ntxiv lossis tsim nyog ntxiv.

2) Sib tov cov khoom xyaw qhuav ntawm gypsum plaster-based peev pwm cov ntaub ntawv nrog dej, raws li cov chaw tsim khoom cov lus qhia. Ua raws li cov lus qhia ntawm txhua yam peev pwm koj xaiv yuav - nws yuav tsum yog ib qho yooj yim ntawm kev ntsuas.

Hnav lub npog ntsej muag lossis lub tshuab ua pa thaum twg ua tau thaum koj ua haujlwm nrog cov hmoov no - nws tsis muaj kev nyab xeeb rau kev nqus pa.

Tsiv mus rau ib zaug koj muaj qhov sib xws ntawm pancake batter.

3) Muab cov pwm pwm tso rau hauv lub tshuab nqus tsev kom tshem tawm cov npuas npuas. Yog tias koj tsis muaj lub tshuab nqus tsev vacuum, koj tuaj yeem cia nws zaum rau 10-20 feeb. Cov npuas huab cua yuav tsim cov qhov, uas yuav tso cai rau cov hlau nkag mus rau hauv thiab tsim ib lub hnab ntim khoom kawg ntawm cov hniav nyiaj hniav kub.

4) Ncuav cov peev pwm sib tov rau hauv lub khob, nyob ib puag ncig cov qauv siv quav ciab. Koj yuav ua tiav koj cov pwm hauv plaster. Rov nqus cov dej sib tov kom tshem tau cov npuas me me ua ntej yuav mus.

Qhwv ib txheej ntawm kais nyob ib ncig ntawm lub khob haus dej, kom ib nrab ntawm daim kab xev zaum saum daim di ncauj thiab pab kom muaj cov plaster los ntawm bubbling.

Cia lub peev pwm teeb tsa. Ua raws li cov lus qhia meej thiab lub sijhawm ziab rau koj cov plaster sib tov ua ntej yuav mus. Thaum ua tiav, tshem tawm daim kab xev thiab txhuam cov plaster ntau dhau los ntawm sab saum toj ntawm pwm.

5) Muab tag nrho lub khob rau hauv lub qhov cub kom txog li 1300 ° F (600 ° C). Nco ntsoov, cov plasters sib txawv yuav muaj qhov sib txawv. Txawm li cas los xij, koj yuav tsum tsis txhob nyob ntawm qhov tsawg dua 1100. Qhov no yuav ua rau cov pwm tawv thiab yaj cov quav ciab, tawm hauv lub chamber hollow nyob rau hauv nruab nrab ntawm cov cam khwb cia hniav nyiaj hniav kub pwm.

Qhov no yuav siv sijhawm txog 12 teev.

Yog tias koj muaj qhov cub hluav taws xob, sim teeb tsa kom maj mam nce qhov kub ntawm 1300. Qhov no tuaj yeem pab tiv thaiv kev tawg.

6) Tshem tawm lub khob los ntawm lub qhov cub thaum kub, thiab xyuas cov pwm hauv qab kom muaj kev cuam tshuam. Xyuas kom tseeb tias cov wax kub tuaj yeem yooj yim tawm ntawm cov pwm, thiab tsis muaj dab tsi thaiv nws. Yog tias tsis muaj dab tsi nyob rau hauv txoj kev, co lub khob maj mam kom paub tseeb tias tag nrho cov wax tuaj. Yuav tsum muaj ib lub pas dej ntawm cov quav ciab nyob rau hauv lub reservoir ntawm lub hwj los yog hauv qab ntawm lub kiln.

Xyuas kom koj hnav hnab looj tes thiab tsom iav.

3. Casting cov hniav nyiaj hniav kub

1) Muab koj cov hlau xaiv nyob rau hauv ib tug pouring crucible, ces yaj nws nyob rau hauv ib tug foundry. Lub melting kub thiab lub sij hawm yuav txiav txim los ntawm hom hlau koj siv. Koj tseem tuaj yeem siv lub tshuab hluav taws xob thiab me me crucible los yaj koj cov nyiaj. Qhov no yog tes pouring hom casting rau me me lub hom phiaj.

2) Siv lub tshuab nqus tsev vacuum hom casting (Nqus Siab Casting Tshuab) txhawm rau muab cov hlau rau hauv pwm. Rau cov hniav nyiaj hniav kub tshaj lij, koj yuav xav tau lub tshuab nqus tsev casting nrog inert roj rau kev tiv thaiv. Qhov no sib npaug faib cov hlau sai, tab sis nws tsis yog tib qho kev xaiv uas koj muaj rau casting. Qhov ntau classic, kev daws yooj yim dua yog kom yooj yim ncuav cov hlau ceev faj rau hauv lub qhov taub sab laug los ntawm lub hauv paus ntawm cov pwm.

Koj tuaj yeem siv lub koob txhaj tshuaj loj, tshwj xeeb hlau los tso cov hlau rau hauv pwm, thiab.

3) Cia cov hlau txias rau 5-10 feeb, ces maj mam muab tso rau hauv dej txias. Lub sij hawm nws yuav tsum tau txias yog nyob ntawm seb, ntawm chav kawm, ntawm cov hlau melted thiab siv. Dunk sai sai thiab cov hlau yuav tawg-dunk lig dhau lawm thiab nws yuav nyuaj rau tshem tawm tag nrho cov plaster ntawm cov hlau tawv.

Saib xyuas lub sijhawm txias rau koj cov hlau ua ntej yuav mus. Uas tau hais tias, yog tias koj nyob hauv lub pickle koj tuaj yeem tos 10 feeb thiab tom qab ntawd dunk hauv dej txias.

Lub plaster yuav tsum pib dissolving tam sim ntawd thaum koj co nws nyob ib ncig ntawm dej txias.

4) Coj mus rhaub cov pwm maj mam nrog rauj txhawm rau tshem tawm cov plaster ntau dhau thiab nthuav tawm cov hniav nyiaj hniav kub. Cais lub raj mis los ntawm lub hauv paus sprue thiab siv koj cov ntiv tes los yog txhuam hniav kom tev tawm ib qho kawg me ntsis daig rau cov hniav nyiaj hniav kub.

4. Ua kom tiav koj cov hniav nyiaj hniav kub

1) Siv lub kaum sab xis grinder nrog lub log txiav tawm kom txiav tawm cov kab hlau los ntawm cov sprues. Txiav cov nyias nyias ntawm cov hlau uas koj xav tau los tsim ib lub qhov los nchuav cov hlau rau hauv. Ib lub tes tuav yuav tsum muaj zog ntau dua.

2) Xav txog thiab da dej kua qaub los yog ntxuav kom huv si ntawm qhov kawg me ntsis ntawm plaster. Cov txheej txheem tua hluav taws feem ntau tso cov hlau dingy thiab qias neeg saib. Koj tuaj yeem saib rau hauv kev ntxuav tshwj xeeb rau qee yam hlau, uas yuav ua rau muaj kev ci ntsa iab ntau dua thiab ua haujlwm yooj yim dua los ntxuav cov khoom tom qab.

3) Tshem tawm qhov tsis sib xws ntawm cov hniav nyiaj hniav kub siv lub log hlau buffing. Siv cov ntaub ntawv, enamel khaub ncaws, polishes, thiab lwm yam los ntxuav cov khoom raws li koj xav tau. Yog tias koj npaj yuav teeb lub pob zeb, ua nws tom qab koj ua tiav polishing.