Sab saum toj Suppliers Induction Melting Rauv Hluav Taws Xob rau Melting Metals Me Me Hluav Taws Xob Melting Rauv Hluav Taws Xob rau Melt Kub

Lub tuam txhab khaws cia rau lub tswv yim kev lag luam "kev tswj hwm kev lag luam, kev ua haujlwm siab thiab kev ua haujlwm zoo, cov neeg siv khoom zoo tshaj plaws rau Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob rau Melting Metals Me Hluav Taws Xob Melting Rauv Hluav Taws Xob Hluav Taws Xob rau Melt Kub, Peb yuav txuas ntxiv siv zog los txhim kho peb cov kev pabcuam thiab muab cov khoom zoo tshaj plaws nrog cov nqi sib tw. Txhua qhov kev nug lossis lus pom zoo txaus siab heev. Thov hu rau peb dawb.

Lub tuam txhab ua rau lub tswv yim ua haujlwm "kev tswj hwm kev tshawb fawb, kev ua haujlwm siab thiab kev ua haujlwm zoo, cov neeg siv khoom zoo tshaj plaws rauTuam Tshoj Induction Melting Rauv thiab Induction Rauv Nqe, Peb muaj lub koob npe nrov rau cov kev daws teeb meem zoo, zoo tau txais los ntawm cov neeg siv khoom hauv tsev thiab txawv teb chaws. Peb lub tuam txhab yuav raug coj los ntawm lub tswv yim ntawm "Sawv hauv Kev Lag Luam Hauv Tebchaws, Taug Kev Hauv Kev Lag Luam Thoob Ntiaj Teb". Peb vam tias peb tuaj yeem ua lag luam nrog cov neeg siv khoom hauv tsev thiab txawv teb chaws. Peb cia siab tias muaj kev koom tes nrog kev koom tes thiab kev txhim kho ib puag ncig!

Technical Parameters

| Qauv No. | HS-CC 1 | HS-CC 2 | HS-CC 3 | HS-CC 4 | HS-CC 8 | HS-CC 20 | HS-CC 30 | HS-CC 50 | HS-CC 100 |

| Qhov hluav taws xob | 220V Ib theem | 380V 50/60Hz, 3 theem | |||||||

| Hwj chim | 5 KW | 8 kWm | 15 KW | 30 KW | 30KW/60KW TSI | 60 kWm | |||

| Max. Temp. | 1500 ° C | ||||||||

| Melting ceev | 2-3 feeb. | 3-5 feeb. | 3-5 feeb. | 10-15 feeb. | 20-25 feeb | 15-25 feeb | |||

| Peev xwm (kub) | 1kg ua | 2kg ua | 4kg ua | 4kg ua | 8kg ua | 20kg ua | 50kg ua | 100 kg | 100 kg |

| Haum rau | K-Gold, Kub, nyiaj, tooj liab | ||||||||

| Qhov siab tshaj plaws lub raj mis txoj kab uas hla | tuaj yeem kho tau | ||||||||

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | ||||||||

| tswj qhov system | Mitsubishi PLC + Tib neeg-tshuab interface ntse tswj qhov system (yeem) | ||||||||

| Nqus (yeem) | Lub tshuab nqus tsev zoo / Lub tshuab nqus tsev German qub -98Kpa | ||||||||

| Qhov ntev | 680x880x1530mm | 1080x980x1850mm | |||||||

| Qhov hnyav | 150 KG | 150 KG | 180 KG | 200 KG | 240 KG | 280 KG | 480 KG | 550 KG | 650 KG |

Khoom Qhia

Hlau ua khoom siv

Hlau Nruam Rolling Mill rau Kub Silver Copper

Qauv No.: HS-3000

Rolling mill Tshuab Hlau Drawing Tshuab rau kub nyiaj saw hlau

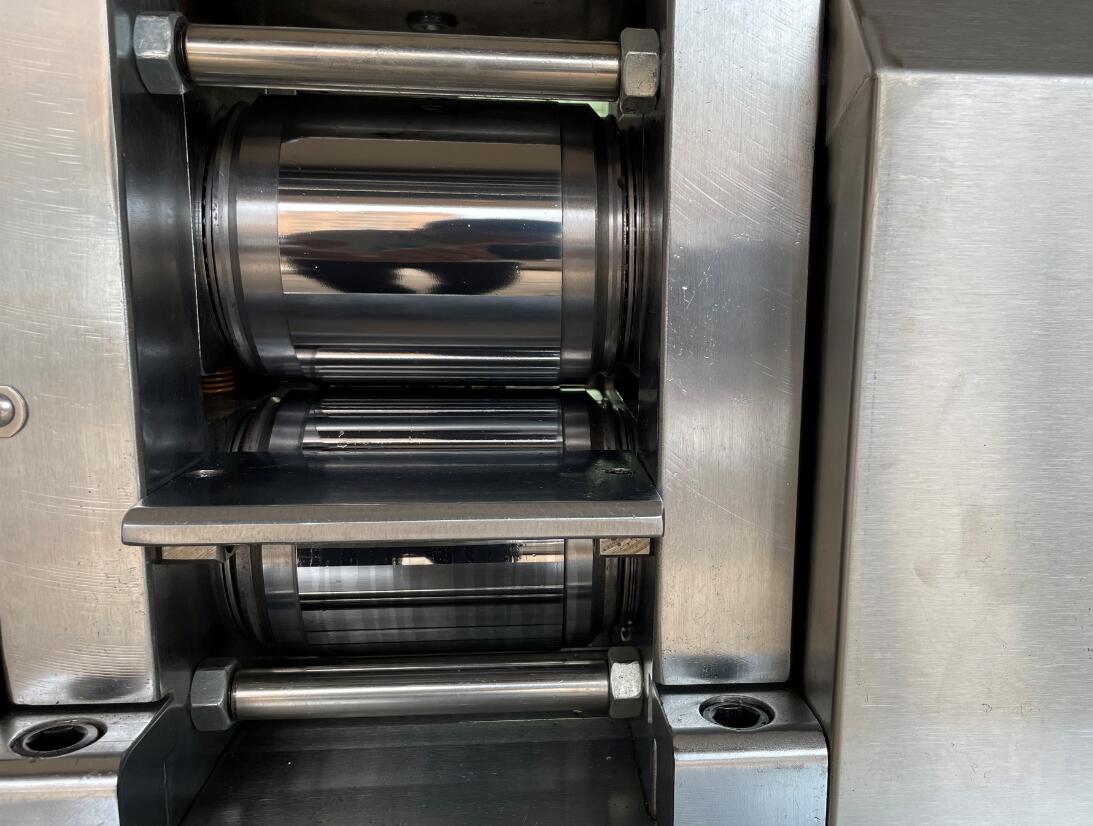

Nws muaj lub siab tsis siv neeg 12-axis kev hloov kho ceev kom ntseeg tau tias tsis muaj kev swb nyob rau hauv nruab nrab ntawm txhua yob, thiab kev ua haujlwm ceev tau hloov kho tas li. Cov neeg ua haujlwm tsuas yog yuav tsum dhau cov khoom siv los ntawm txhua tus menyuam nyob rau hauv qhov kev txiav txim ntawm cov menyuam yaus ib zaug, tsis tas yuav kho cov menyuam nqa. Nws yog siv rau precious hlau hlau ua, dav siv rau hlau xov hlau manufacturing kev lag luam.

| Qhov hluav taws xob | 380V, 50Hz, 3 theem |

| Hwj chim | 8 kWm |

| Roller txoj kab uas hla | 96mm (Cov khoom siv Roller: SKD11) |

| Roller kom muaj nuj nqis | 12 sib |

| Cov khoom siv ntau yam | input 8.2 × 8.2 hli; tso zis 3.5 × 3.5mm los yog input 3.5 × 3.5mm; tso zis 1.0 × 1.0mm |

| Max dov ceev | 45m / min (925 nyiaj: kwv yees 4.9kg) |

| Qhov ntev | 2800x900x1300mm |

| Luj: approx | 2500 kg |

| Tswj qhov system | zaus tswj ceev, lub cev muaj zog tsav dov |

| Txoj kev sau cov hlau | Sagging Gravity nqa |

| Cov khoom cua txias | Txau lubricating kua txias |

| Daim ntawv thov | Kub, K-kub, nyiaj, tooj liab, alloy. |

Heavy Duty Hlau Drawing Tshuab rau Kub Silver Copper

Qauv TSIS MUAJ: HS-1126

Nws yog lub luag haujlwm hnyav hom hlau kos duab, daim ntawv thov kub, nyiaj, tooj liab, thiab lwm yam. Kev kos duab muaj peev xwm txog li 8 hli, qhov tsawg kawg nkaus yuav yog 0.2 hli. Nws yog siv rau precious hlau hlau ua, dav siv rau hlau xov hlau manufacturing kev lag luam.| Qhov hluav taws xob | 380V, 50Hz, 3 theem |

| Hwj chim | 5.5KW * 2 |

| Kos duab kab diam | 0.2-8 hli |

| Roller hardness | 60-62 HRC |

| Cov khoom siv ntau yam | kub, K-kub, nyiaj, tooj liab, alloy, thiab lwm yam |

| Max dov ceev | 32m / min |

| Tsav ceev | 36 rpm / min. (kev tswj ceev) |

| Qhov ntev | 1900x800x1400mm |

| Luj: approx | kwv yees. 9 00kg |

| Hlau collection device | suav nrog |

| Cov khoom cua txias | Txau dej txias |

8HP Ob Chav Lub Taub Hau Hluav Taws Xob Hlau Rolling Zeb (ob chav ceev)

Hnyav luag hauj lwm hom ob lub taub hau hlau dov zeb tshuab yog thov rau jewellery factories thiab precious hlau kev lag luam. Nws yog nruab nrog hlau winding ntaus ntawv. Yooj yim rau xaim manufacturers.

Rau cov chaw tsim khoom lag luam jewelery, feem ntau lawv siv nws ua cov xov hlau, tom qab ntawd ua ntau hom kev txuas txuas rau kub thiab nyiaj, cov khoom siv tooj liab. Hlau thiab daim ntawv loj tuaj yeem raug kho los ntawm lub tshuab no raws li kev thov.

Specification

| Qauv No. | HS-D8HP TSI |

| Qhov hluav taws xob | 380V, 50/60Hz |

| Hwj chim | 5.5 KW TSI |

| Roller | Txoj kab uas hla 130/120 × 188mm |

| Roller hardness | 60-61 ° |

| Qhov ntev | 1080 × 1180 × 1480mm |

| Qhov hnyav | Kwv yees li. 8 50kg |

| Ntxiv muaj nuj nqi | tsis siv neeg lubrication; iav kis tau tus mob |

| Nta | Rolling 0.9-10.5mm square hlau; ob zaug ceev; du nto ntawm cov hlau, qhov loj me, tsis muaj qis pem hauv ntej; tsis siv neeg nqa; electrostatic plua plav ntawm tus ncej, zoo nkauj tawv chromium |

12 Pass Wire Drawing Tshuab

Lub tshuab nqus hlau, tseem hu ua hlau dhau tshuab, nws yog siv los txo cov hlau loj. Lub tshuab no nruab nrog 12 pass uas tso cai rau koj tso 12 hlau tuag ib zaug. Lub peev xwm rau lub tshuab no yog los ntawm qhov siab tshaj 1.2mm mus rau yam tsawg kawg nkaus 0.1mm. Nws yog ib lub tshuab tsim nyog rau ewelry saw manufacturing cog. Nws kuj yog siv rau lwm yam khoom muaj nqi hlau hlau tsim lub hom phiaj.

| Qauv No. | UAS-1124 |

| Qhov hluav taws xob | 380V 3 theem, 50/60Hz |

| Hwj chim | 3.5 KW TSI |

| Ceev tshaj plaws | 55 meters / feeb |

| Muaj peev xwm | 1.2mm-0.1 hli |

| Txoj kev txias | Tsis siv neeg ua kua txias |

| Hlau pwm | customized (muag nyias) |

| Tshuab loj | 1680 * 680 * 1280 hli |

| Qhov hnyav | Kwv yees li. 350kg ua |

Cov khoom siv ua daim ntawv

10HP Daim Ntawv Rolling Mill

| MODEL NO. | HS-8HP TSI | HS-10 TSI |

| Hom Lub Npe | HASUNG | |

| Qhov hluav taws xob | 380V 50/60Hz, 3 theem | |

| Hwj chim | 5.5 KW TSI | 7.5 kWm |

| Roller | Txoj kab uas hla 130/120 × 248mm | luas 150 x 220 mm |

| tawv | 60-61 ° | |

| Qhov ntev | 980 × 1180 × 1480mm | 1080x580x1480mm |

| Qhov hnyav | kwv yees. 600 kg | kwv yees. 8 00kg |

| Muaj peev xwm | Qhov siab tshaj plaws Rolling thickness yog li 25 hli | Qhov siab tshaj plaws Rolling thickness yog mus txog 35mm |

| Qhov zoo | Lub thav duab yog electrostatically plua plav, lub cev yog plated nrog cov hniav tawv chrome, thiab stainless hlau npog zoo nkauj thiab siv tau yam tsis muaj xeb. ib leeg-ceev / ob zaug ceev | |

| Tom qab Warranty Service | Video technical support, Kev them nyiaj yug online, Spare qhov chaw, thaj chaw tu thiab kho kev pabcuam | |

Tungsten Carbide Daim iav Deg Sheet Rolling Mill

| Qauv No. | HS-M5HP TSI | HS-M8HP | |||

| Hom Lub Npe | Hasung | ||||

| Qhov hluav taws xob | 380V 3 theem; 50/60 hli | ||||

| Hwj chim | 3.7 kwm | 3.7 kwm | 5.5 kwv | ||

| Tungsten Roller loj | luas 90 x 60 mm | luas 90 x 90 mm | luas 100 x 100 mm | luas 120 x 100 mm | |

| tawv | 92-95 ° | ||||

| Khoom siv | imported tungsten steel billet | ||||

| Qhov ntev | 880 × 580 × 1400 hli | 880 × 580 × 1400 hli | 880 × 580 × 1400 hli | ||

| Qhov hnyav | kwv yees. 450kg ua | kwv yees. 450kg ua | kwv yees. 4 80kg | ||

| Feature | Nrog lubrication, iav tsav; Rolling sheet thickness 10mm, thinnest 0.1 hli; extruded ntawv hlau nto iav nyhuv; static hmoov txau rau ntawm tus ncej, zoo nkauj tawv chrome plating, stainless hlau | ||||

Lub tuam txhab ua raws li lub tswv yim kev lag luam "kev tswj hwm kev tshawb fawb, kev ua haujlwm zoo thiab kev ua haujlwm zoo, cov neeg siv khoom zoo tshaj plaws rau Cov Khoom Siv Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob rau Melting Metals Cov Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob Hluav Taws Xob rau Melt Kub, nyiaj, platinum, thiab lwm yam. Peb yuav txuas ntxiv mus. los txhim kho peb cov kev pabcuam thiab muab cov khoom zoo tshaj plaws nrog cov nqi sib tw. Txhua qhov kev nug lossis lus pom zoo txaus siab heev. Thov hu rau peb dawb.

Cov neeg muag khoom sab saum tojTuam Tshoj Induction Melting Rauv thiab Induction Rauv Nqe, Peb muaj lub koob npe nrov rau cov kev daws teeb meem zoo, zoo tau txais los ntawm cov neeg siv khoom hauv tsev thiab txawv teb chaws. Peb lub tuam txhab yuav raug coj los ntawm lub tswv yim ntawm "Sawv hauv Kev Lag Luam Hauv Tebchaws, Taug Kev Hauv Kev Lag Luam Thoob Ntiaj Teb". Peb vam tias peb tuaj yeem ua lag luam nrog cov neeg siv khoom hauv tsev thiab txawv teb chaws. Peb cia siab tias muaj kev koom tes nrog kev koom tes thiab kev txhim kho ib puag ncig!

Ua strips, rods, nplooj ntawv, kav dej, thiab lwm yam.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur