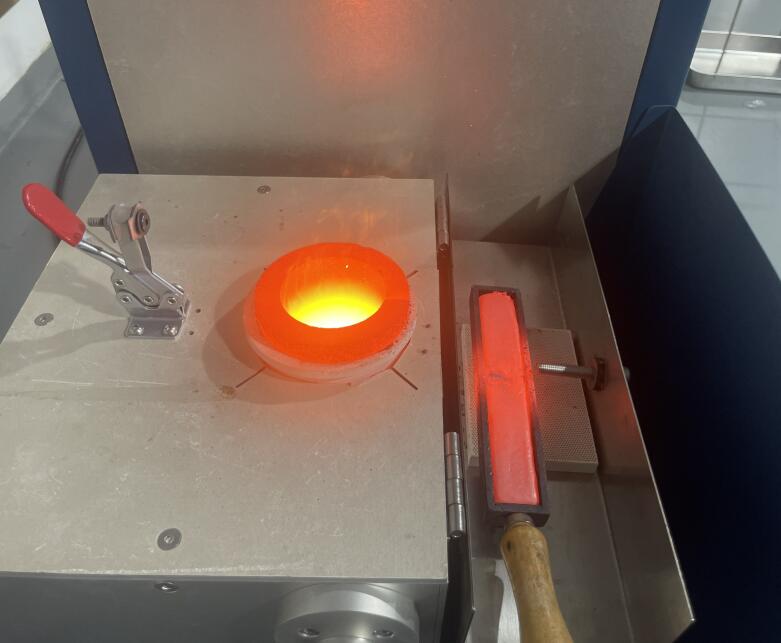

Tilting induction melting tshuab rau kub Silver Copper 2kg 3kg 4kg 5kg 6kg

Nta

Hasung Dual Siv kub thiab platinum melting rauv tuaj yeem ua tau zoo thiab siv zog yaj platinum, nyiaj, kub, palladium thiab qee yam alloys.

Qhov loj me me ntawm platinum melting rauv ua rau nws yooj yim txav mus los.

Hasung multipurpose kub thiab platinum melting rauv kuj yog tsim rau me me scale melting vim hais tias nws melts txog 1g rau 2kg ntawm hlau ib zaug, yog li ntawd, cov lag luam me uas yuav tsum tau melting yuav tsum tsis txhob txhawj txog kom tau ib tug melting rauv uas tsuas yog raws li lawv cov kev xav tau melting.

Kev siv hluav taws xob ntawm lub platinum melting rauv yog 15kw, qhov no txhais tau hais tias lub zog tau txais kev cawmdim thaum yaj nrog lub platinum melting rauv thiab koj tsis tas yuav txhawj xeeb txog kev siv nyiaj ntxiv rau lub zog ntxiv.

Hasung multipurpose kub thiab platinum melting rauv tuaj yeem ua tau raws li qhov xav tau ntawm melting kev xav tau ntawm lub khw muag khoom kim heev, kev ua si hlau diggers, cov koom haum tshawb fawb thiab rov ua dua qub hlau.

Hasung multi-purpose kub thiab platinum melting rauv yog ib puag ncig zoo siv xws li lub qhov cub tsis tsim cov pa phem lossis ua suab nrov. Nws kuj tseem muaj kev nyab xeeb rau cov neeg ua haujlwm ua haujlwm raws li cov hlau molten tsis tshwm sim.

Lub sij hawm melting yog ceev heev, lub platinum melting rauv melts ntawm 2100 ℃ nyob rau hauv 2 feeb, yog li, ua rau koj ua hauj lwm thiab ntau lawm efficiency.

Tag nrho cov hlau melted nrog peb lub platinum melting rauv feem ntau muaj ib tug zoo sib xws li hais tias thaum xws li hlau yog cam khwb cia, nws muaj ib tug high-zoo tag.

Lub electromagnetic induction stirring muaj nuj nqi tam sim no nyob rau hauv lub platinum melting rauv ua rau cov txheej txheem melting npaum los ntawm kev xa cov cua sov sib npaug thiab txhua qhov ntawm cov hlau yog melted tusyees. Qhov no kuj txhais tau hais tias tag nrho cov cua sov yuav tsum tau rau melting yog tag nrho siv nyob rau hauv lub cub tawg, yog li ntawd, tsis muaj qhov kub ntawm lub melting ib puag ncig.

Lub hauv-tsim dej-txias system tam sim no nyob rau hauv lub cub tawg ua rau lub cub tawg melting kub los tswj, yog li tiv thaiv overheating.

Lub tshuab cua sov induction tam sim no nyob rau hauv lub platinum melting rauv ua rau lub electromagnetic induction ua tau, uas txhais tau hais tias tag nrho cov zog uas yuav tsum tau rau melting yog kiag li siv nyob rau hauv lub melting rauv.

Lub platinum melting rauv yog yooj yim heev rau kev khiav lag luam. Cov tswj vaj huam sib luag ua rau nws yooj yim rau koj los tswj thiab saib xyuas cov txheej txheem melting.

Hasung multi-purpose kub thiab platinum melting rauv yog ib puag ncig zoo vim tsis muaj cua sov tshwm sim thaum siv, tsis muaj roj tso tawm thiab tsis muaj suab nrov tshwm sim thaum melting nrog platinum melting rauv.

Lub peev xwm melting ntawm txhua qhov melting nto mus txog 2100 ℃ feem ntau yuav siv zog ntau dhau, tab sis peb cov khoom siv kub melting tsuas yog yuav tsum tau 15kw pib melting ua kom nws raug nqi.

Tag nrho 8kg melting yog ua tau zoo nyob rau hauv 3 feeb, ib tug undefeatable feature ntawm cov kub melting khoom rau muag. Qhov ceev ntawm melting pab koj kom tau raws li tag nrho cov melting xav tau sai thiab yooj yim dua.

Kub, nyiaj, tooj liab, tooj liab, platinum thiab lwm yam alloys tuaj yeem ua tiav nrog peb cov khoom siv kub melting. Qhov no ua rau koj txuag nyiaj ntawm lwm cov khoom siv melting.

Cov dej twj tso kua mis tam sim no nyob rau hauv peb cov khoom siv smelting kub ua rau nws tswj tau qhov kub thiab txias thaum melting tsis tu ncua. Li no, koj txuag nyiaj ntawm cov khoom siv cua txias.

Peb cov khoom siv kub melting yog tsim rau yaj hlau rau kev tshawb fawb thiab kev qhia, foundries, recycling hlau hauv khw muag khoom, thiab lwm yam.

Nyob rau hauv kev hwm rau nws cov kev cuam tshuam rau ib puag ncig, lub suab nrov ntawm cov khoom kub thiab nyiaj melting thaum lub sij hawm cov txheej txheem ntawm melting yog tsis tshua muaj thiab tsis muaj emission ntawm cov pa roj, pa taws los yog plua plav kuj tsawg.

Piv nrog rau cov hluav taws kub tsis kam thiab cov propane burners, Hasung kub melting cov cuab yeej ua kom tsis muaj hlau thaum lub sij hawm melting txheej txheem, ua rau peb cov khoom siv melting ntau npaum li ob qho tib si resistant furnaces thiab propane burners.

Peb cov khoom kub thiab nyiaj melting tuaj yeem ua haujlwm tsis tu ncua ntev li 24 teev.

Tus neeg teb xov tooj ntawm cov khoom siv kub melting muaj tag nrho cov kev tswj ntawm cov melting tsis. Yog tias muaj teeb meem tshwm sim, lub omni-directional ceeb toom system pab txhawb lub tswb thaum cov ntsiab lus muaj teeb meem tau mus txog thaum lub sij hawm yaj, yog li ua kom muaj kev nyab xeeb ntawm tus neeg siv.

Kev tu cov khoom kub thiab nyiaj melting yog ib qho yooj yim raws li cov crucibles yog detachable thiab tuaj yeem ntxuav tom qab txhua txheej txheem melting.

Technical Parameters

| Qauv No. | HS-TF 2 | HS-TF 3 | HS-TF4 | HS-TF5 | HS-TF6 | HS-TF8 | HS-TF10 |

| Hwj chim | 8 KW/15KW | 15 KW | 15KW / 20KW TSI | ||||

| Qhov hluav taws xob | 380V, 50Hz, 3 theem | ||||||

| Max Temp | 1600 ° C | ||||||

| Lub sij hawm yaj | 2-3 feeb. | 3-5 feeb. | 3-6 feeb. | 4-8 feeb. | 5-8 feeb. | 5-8 feeb. | 6-8 feeb. |

| Temp raug | ± 1 ° C (siv PID tswj kev xaiv) | ||||||

| PID temp tswj | Xaiv tau | ||||||

| Peev xwm (Gold) | 2 KG | 3 KG | 4 KG | 5 KG | 6 KG | 8 KG | 10 KG |

| Daim ntawv thov | Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys | ||||||

| Hom cua txias | Dej chiller (muag cais) los yog dej khiav (dej twj tso kua mis) | ||||||

| Txoj kev cua sov | Lub teb chaws Yelemees IGBT Induction cua sov tshuab | ||||||

| Qhov ntev | 90 x 48 x 100 cm | ||||||

| Net Nyhav (kwv yees) | 90kg ua | 90kg ua | 100 kg | 110kg ib | 120 kg | 130kg ib | 160 kg |

| Shipping Nyhav (kwv yees) | 160 kg | 175kg ua | 180kg ib | 190kg ib | 200 kg | 220kg ib | 220kg ib |

Khoom Qhia

-18.png)

Title: Qhov zoo ntawm Hasung phau ntawv qaij casting induction melting rauv

Nyob rau hauv lub ntiaj teb no ntawm hlau casting thiab casting kev khiav hauj lwm, phau ntawv qaij-cam khwb cia induction melting rauv tau los ua ib tug indispensable cuab tam vim lawv efficiency, kev ruaj ntseg thiab innovation. Qhov kev tsim hluav taws xob siab tshaj no muaj ntau yam txiaj ntsig rau cov neeg ua haujlwm thiab cov chaw tsim khoom, ua rau nws muaj kev xaiv nrov hauv kev lag luam. Hauv blog no, peb yuav tshawb txog ntau yam txiaj ntsig ntawm phau ntawv qaij-cam khwb cia induction melting rauv thiab yuav ua li cas nws cov yam ntxwv tshiab, xws li lub tais tig rau graphite pwm thiab kev ua haujlwm zoo, pab txhawb rau nws cov kev ua tau zoo.

Kev tuav qaij ncuav induction melting rauv muaj ntau yam zoo uas ua rau lawv muaj txiaj ntsig zoo hauv kev ua haujlwm hlau. Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm lub qhov cub no yog nws phau ntawv qaij ua haujlwm, uas tso cai rau kev tswj xyuas meej ntawm cov txheej txheem nchuav. Tsis tsuas yog qhov no ua kom zoo ib yam thiab txawm tias nchuav, nws tseem txo qhov kev pheej hmoo ntawm kev tawg lossis nchuav, muab qhov chaw ua haujlwm nyab xeeb rau cov neeg ua haujlwm. Lub peev xwm los tig lub qhov cub ua rau cov neeg ua haujlwm tau yooj yim dua thiab tswj tau, tso cai rau lawv nchuav cov hlau molten nrog yooj yim thiab raug.

Tsis tas li ntawd, kev tsim kho tshiab ntawm graphite pwm rotating tray ua rau Hasung phau ntawv tilting pouring induction melting rauv txawv ntawm cov khoom siv tsoos melting. Qhov kev hloov tshiab no ua rau lub qhov cub kom haum rau ntau yam pwm, yog li ua kom muaj txiaj ntsig thiab tsim khoom ntawm cov txheej txheem casting. Rotating pallets pub rau seamless pwm hloov, txo downtime thiab simplifying ntau lawm. Tsis tas li ntawd, lub tshuab ua kom zoo tshaj plaws ntawm cov khoom siv tes ua kom muaj kev ruaj ntseg thiab kev ntseeg siab, ua rau nws muaj peev xwm mus ntev rau cov chaw tsim khoom thiab cov khoom siv hlau.

Kev tuav qaij ncuav induction melting rauv muaj ntau yam zoo uas ua rau lawv muaj txiaj ntsig zoo hauv kev ua haujlwm hlau. Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm lub qhov cub no yog nws phau ntawv qaij ua haujlwm, uas tso cai rau kev tswj xyuas meej ntawm cov txheej txheem nchuav. Tsis tsuas yog qhov no ua kom zoo ib yam thiab txawm tias nchuav, nws tseem txo qhov kev pheej hmoo ntawm kev tawg lossis nchuav, muab qhov chaw ua haujlwm nyab xeeb rau cov neeg ua haujlwm. Lub peev xwm los tig lub qhov cub ua rau cov neeg ua haujlwm tau yooj yim dua thiab tswj tau, tso cai rau lawv nchuav cov hlau molten nrog yooj yim thiab raug.

Tsis tas li ntawd, kev tsim kho tshiab ntawm graphite pwm rotating tais ua rau phau ntawv tilting pouring induction melting rauv txawv los ntawm cov khoom siv melting ib txwm. Qhov kev hloov tshiab no ua rau lub qhov cub kom haum rau ntau yam pwm, yog li ua kom muaj txiaj ntsig thiab tsim khoom ntawm cov txheej txheem casting. Rotating pallets pub rau seamless pwm hloov, txo downtime thiab simplifying ntau lawm. Tsis tas li ntawd, lub tshuab ua kom zoo tshaj plaws ntawm cov khoom siv tes ua kom muaj kev ruaj ntseg thiab kev ntseeg siab, ua rau nws muaj peev xwm mus ntev rau cov chaw tsim khoom thiab cov khoom siv hlau.

Ntxiv nrog rau kev nyab xeeb thiab kev tsim kho tshiab, phau ntawv qaij-thiab-cam khwb cia induction melting furnaces kuj muaj qhov zoo ntawm kev siv hluav taws xob thiab kev ua haujlwm zoo. Induction cua sov tshuab siv nyob rau hauv cov furnaces melts hlau sai thiab meej, txo lub zog noj thiab cov nqi khiav hauj lwm. Qhov no ua rau lub cub tawg tsis yog tsuas yog ib puag ncig tus phooj ywg, tab sis kuj tseem muaj txiaj ntsig zoo rau cov chaw tsim khoom thiab cov chaw hlau casting. Lub peev xwm ua tau zoo melting efficiency thaum txo qis zog noj yog qhov zoo dua ntawm phau ntawv qaij-cam khwb cia induction melting furnaces.

Tsis tas li ntawd, phau ntawv qaij lub ncuav induction melting rauv yog tsim los ua kom tau raws li qhov xav tau ntawm ntau hom kev ua haujlwm hlau casting, muab ntau yam thiab hloov tau rau ntau yam kev siv. Txawm hais tias rau kev tsim khoom me me lossis kev ua haujlwm loj loj, lub tshuab hluav taws xob tuaj yeem hloov mus rau qhov sib txawv melting muaj peev xwm thiab hom hlau, ua rau nws muaj ntau yam thiab siv tau rau cov tuam ntxhab. Qhov yooj ntawm lub cub tawg tso cai rau seamless kev koom ua ke rau hauv cov txheej txheem ntau lawm, ua kom tag nrho cov efficiency thiab productivity.

Nyob rau hauv cov ntsiab lus, phau ntawv qaij-cam khwb cia induction melting rauv muaj ntau yam zoo uas ua rau lawv yog ib qho tseem ceeb rau cov hlau casting thiab foundry ua hauj lwm. Nws cov yam ntxwv kev nyab xeeb, tsim tshiab, zoo craftsmanship, zog efficiency thiab versatility ua rau nws yog ib qho tseem ceeb peev rau manufacturers nrhiav optimize lawv casting txheej txheem. Nrog nws cov kev tswj xyuas meej ntawm cov txheej txheem pouring, lub tswv yim rotating tais rau graphite pwm thiab kev ua haujlwm raug nqi, lub qhov cub no yog qhov kev ua si hloov pauv rau kev lag luam hlau casting. Raws li qhov kev thov rau cov khoom siv zoo, cov khoom siv melting zoo txuas ntxiv mus, phau ntawv qaij-cam khwb cia induction melting rauv ua ib qho kev txhim khu kev qha thiab qib siab rau cov tuam txhab nrhiav kom lawv cov peev txheej casting.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur