WIRE BONDING

KEV PAB CUAM FACT SHEET

Hlau Bonding yog dab tsi?

Kev sib txuas ntawm cov hlau yog cov txheej txheem los ntawm qhov ntev ntawm txoj kab uas hla me me ntawm cov hlau mos hlau txuas nrog rau qhov sib xws ntawm cov hlau nplaum uas tsis siv cov vuam, flux, thiab qee zaum siv cov cua sov siab tshaj 150 degrees Celsius. Cov hlau mos muaj xws li Kub (Au), tooj liab (Cu), Nyiaj (Ag), Aluminium (Al) thiab cov hlau xws li Palladium-Silver (PdAg) thiab lwm yam.

Nkag siab txog Cov Txheej Txheem Hlau Bonding thiab Cov Txheej Txheem rau Micro Electronics Assembly Applications.

Wedge Bonding Techniques / Txheej Txheem: Ribbon, Thermosonic Pob & Ultrasonic Wedge Bond

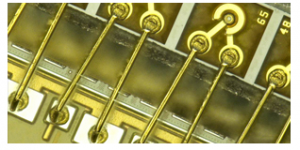

Hlau bonding yog txoj kev ua kev sib tshuam ntawm ib qho kev sib koom ua ke (IC) los yog cov khoom siv semiconductor zoo sib xws thiab nws cov pob lossis leadframe thaum tsim khoom. Nws kuj tau siv tam sim no los muab kev sib txuas hluav taws xob hauv Lithium-ion roj teeb pob cov rooj sib txoos.Wire bonding feem ntau suav hais tias yog tus nqi zoo tshaj plaws thiab hloov tau yooj yim ntawm cov khoom siv hluav taws xob sib txuas hauv microelectronic, thiab yog siv nyob rau hauv feem ntau ntawm semiconductor pob khoom tsim hnub no. yog ob peb txoj kev sib txuas cov hlau, suav nrog: Thermo-Compression Wire Bonding:

Thermo-compression hlau bonding (sib txuas rau tej qhov chaw (feem ntau Au) ua ke nyob rau hauv ib tug clamping quab yuam nrog siab interface kub, feem ntau ntau dua 300 ° C, los tsim ib tug weld), tau pib tsim nyob rau hauv 1950's rau microelectronics interconnects, tab sis qhov no yog. sai hloov los ntawm Ultrasonic & Thermosonic bonding nyob rau hauv lub 60's raws li qhov tseem ceeb interconnect technology. Thermo-compression bonding tseem siv tau rau cov ntawv thov niche niaj hnub no, tab sis feem ntau zam los ntawm cov tuam txhab vim qhov siab (feem ntau ua rau muaj kev puas tsuaj) qhov kub ntawm qhov xav tau txhawm rau ua kom muaj kev vam meej.Ultrasonic Wedge Wire Bonding:

Nyob rau xyoo 1960's Ultrasonic wedge wire bonding tau dhau los ua txoj kev sib txuas tseem ceeb. Daim ntawv thov ntawm qhov kev vibration siab (ntawm lub resonating transducer) rau cov cuab yeej sib txuas nrog lub zog clamping ib txhij, tso cai rau Aluminium thiab kub xov hlau yuav tsum tau welded ntawm chav tsev kub. Qhov no Ultrasonic kev co pab tshem tawm cov kab mob (oxides, impurities, thiab lwm yam) los ntawm qhov chaw sib txuas thaum pib ntawm lub voj voog sib txuas, thiab txhawb kev loj hlob ntawm intermetallic kom txhim kho thiab ntxiv dag zog rau daim ntawv cog lus. Feem ntau zaus rau kev sib txuas yog 60 - 120 KHz.Cov txheej txheem ultrasonic wedge muaj ob lub ntsiab txheej txheem thev naus laus zis: Loj (hnyav) hlau txuas rau> 100µm txoj kab uas hla ntawm cov xov hlau Fine (me me) hlau sib txuas rau <75µm txoj kab uas hla ntawm cov xov hlau piv txwv ntawm kev sib raug zoo Ultrasonic bonding cycles tuaj yeem pom ntawm no rau cov hlau zoo thiab ntawm no rau cov xaim loj.Ultrasonic wedge hlau bonding siv ib qho kev sib txuas tshwj xeeb cuab tam los yog "ntim," feem ntau yog tsim los ntawm Tungsten Carbide (rau Aluminium hlau) los yog Titanium Carbide (rau kub hlau) nyob ntawm cov txheej txheem yuav tsum tau thiab hlau diameters; ceramic tipped wedges rau cov ntawv sib txawv kuj muaj.Thermosonic Wire Bonding:

Qhov twg yuav tsum tau muaj cua sov ntxiv (feem ntau yog rau cov hlau kub, nrog kev sib txuas sib txuas hauv thaj tsam ntawm 100 - 250 ° C), cov txheej txheem hu ua Thermosonic hlau sib txuas. Qhov no muaj qhov zoo tshaj plaws ntawm cov txheej txheem thermo-compression, raws li qhov ntsuas kub qis dua yuav tsum tau (Au kev sib koom ua ke ntawm chav tsev kub tau hais, tab sis hauv kev xyaum nws tsis ntseeg tau yam tsis muaj cua sov ntxiv). Thermosonic Ball Bonding:

Lwm daim ntawv ntawm Thermosonic hlau bonding yog Pob Bonding (saib lub pob nyiaj voj voog ntawm no). Cov txheej txheem no siv cov cuab yeej ceramic capillary bonding los ntawm cov qauv tsim los ua ke kom zoo tshaj plaws hauv ob qho tib si thermo-compression thiab ultrasonic bonding yam tsis muaj qhov tsis zoo. Thermosonic kev co ua kom lub interface kub tseem qis, thaum thawj qhov kev sib tshuam, cov thermally-compressed pob ntawv tso cai rau cov hlau thiab cov ntawv cog lus thib ob muab tso rau hauv txhua qhov kev taw qhia, tsis nyob rau hauv-kab nrog thawj daim ntawv cog lus, uas yog ib qho kev txwv hauv Ultrasonic hlau sib txuas. . Rau cov khoom siv tsis siv neeg, ntim siab, cov khoom sib txuas pob tau nrawm dua li Ultrasonic / Thermosonic (Ntxhiab) cov hlua khi, ua rau Thermosonic pob sib txuas cov cuab yeej sib txuas tseem ceeb hauv microelectronics rau 50+ xyoo dhau los.Ribbon Bonding:

Ribbon bonding, siv cov ntaub nplaum nplaum, tau muaj zog hauv RF thiab Microwave electronics rau ntau xyoo lawm (ribbon muab kev txhim kho tseem ceeb hauv cov teeb liab poob [cov nyhuv ntawm daim tawv nqaij] piv rau cov kab ib txwm muaj). Cov ribbons kub me me, feem ntau txog li 75µm dav thiab 25µm tuab, yog sib koom ua ke los ntawm cov txheej txheem Thermosonic nrog lub ntsej muag lub ntsej muag lub ntsej muag loj.Aluminium ribbons txog li 2,000µm dav thiab 250µm tuab kuj tuaj yeem txuas nrog Ultrasonic wedge txheej txheem, xws li qhov yuav tsum tau rau qis voj, siab ceev interconnects tau nce.

Dab tsi yog kub bonding hlau?

Kub hlau bonding yog txheej txheem uas kub hlau txuas mus rau ob lub ntsiab lus nyob rau hauv ib qho kev sib dhos los tsim ib qho kev sib txuas los yog ib txoj hauv kev siv hluav taws xob. Thaum tshav kub kub, ultrasonics, thiab quab yuam yog tag nrho cov neeg ua hauj lwm los tsim cov Symptoms ntsiab lus rau cov hlau kub.Qhov txheej txheem ntawm kev tsim cov Symptoms point pib nrog tsim ib lub pob kub ntawm lub ntsis ntawm cov hlau daim ntawv cog lus cuab tam, lub capillary. Lub pob no yog nias rau ntawm lub rhuab los ua ke nto thaum thov ob qho tib si ib daim ntawv thov-specific nqi ntawm quab yuam thiab ib zaus ntawm 60kHz - 152kHz ntawm ultrasonic suab nrog lub cuab tam.Thaum thawj daim ntawv cog lus tau ua, cov hlau yuav manipulated nyob rau hauv ib tug nruj tswj. yam uas tsim cov voj voog tsim nyog rau lub rooj sib txoos geometry. Qhov thib ob daim ntawv cog lus, feem ntau hu ua lub plooj, yog tom qab ntawd tsim ntawm lwm qhov chaw los ntawm nias nrog cov hlau thiab siv lub clamp los rhuav cov hlau ntawm daim ntawv cog lus.

Kub hlau bonding muaj ib txoj kev sib txuas hauv cov pob khoom uas muaj hluav taws xob zoo heev, ze li qhov kev txiav txim siab ntau dua li qee cov khoom siv. Tsis tas li ntawd, cov xov hlau kub muaj qhov siab oxidation kam rau ua piv rau lwm cov ntaub ntawv hlau thiab yog softer dua li feem ntau, uas yog qhov tseem ceeb rau qhov chaw rhiab heev.

Cov txheej txheem kuj tuaj yeem sib txawv raws li qhov xav tau ntawm kev sib dhos. Nrog rau cov ntaub ntawv rhiab heev, lub pob kub tuaj yeem muab tso rau ntawm qhov chaw sib txuas thib ob los tsim kom muaj kev sib raug zoo thiab "softer" daim ntawv cog lus los tiv thaiv kev puas tsuaj rau saum npoo ntawm cov khoom. Nrog rau qhov chaw nruj, ib lub pob tuaj yeem siv los ua qhov chaw pib rau ob daim ntawv cog lus, tsim "V" daim ntawv cog lus. Thaum daim ntawv cog lus yuav tsum muaj zog dua, lub pob tuaj yeem muab tso rau saum lub plooj los tsim kev ruaj ntseg daim ntawv cog lus, ua kom muaj kev ruaj ntseg thiab lub zog ntawm cov hlau. Ntau yam kev siv sib txawv thiab kev hloov pauv rau kev sib txuas ntawm cov xaim yog ze li qhov tsis muaj kev txwv thiab tuaj yeem ua tiav los ntawm kev siv cov software automated ntawm Palomar's wire bond systems.

Kev txhim kho ntawm cov hlau txuas:

Kev sib txuas ntawm hlau tau pom nyob rau hauv lub teb chaws Yelemees xyoo 1950's los ntawm kev soj ntsuam zoo heev thiab tom qab ntawd tau tsim los rau hauv cov txheej txheem tswj tau zoo. Niaj hnub no nws tau siv dav rau kev sib txuas ntawm cov khoom siv hluav taws xob sib txuas rau cov khoom siv hluav taws xob rau cov pob khoom, disk tsav lub taub hau rau pre-amplifiers, thiab ntau lwm yam kev siv uas tso cai rau cov khoom siv niaj hnub ua me me, "smarter", thiab ntau dua.

Daim ntawv thov Bonding Wires

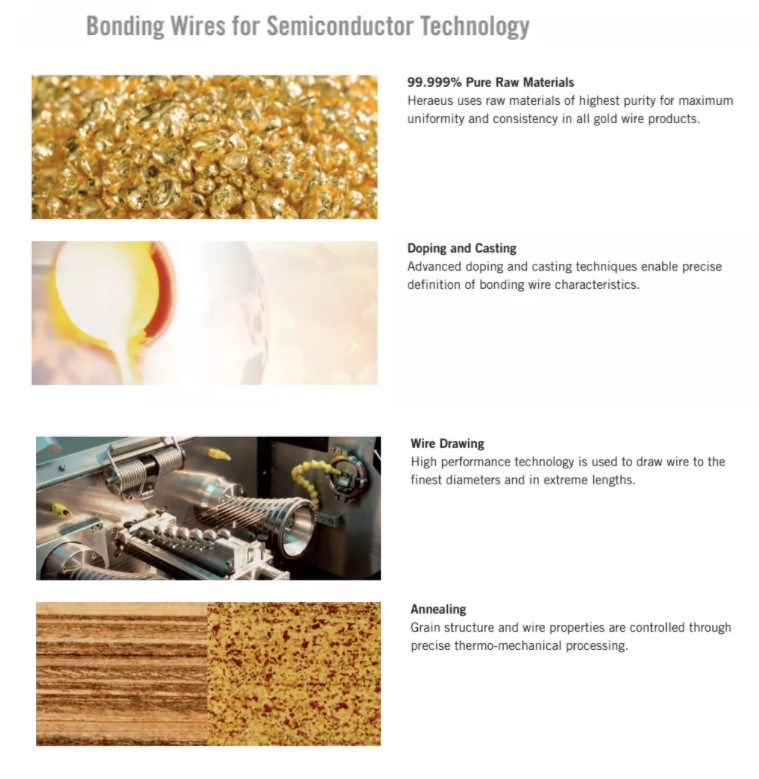

Kev nce miniaturization hauv electronics tau ua rau

nyob rau hauv kev sib txuas xov hlau ua ib qho tseem ceeb ntawm

electronic assemblies.

Rau lub hom phiaj no zoo thiab ultrafine bonding hlau ntawm

Kub, txhuas, tooj liab thiab palladium yog siv. Siab tshaj

kev xav tau yog ua los ntawm lawv qhov zoo, tshwj xeeb yog hais txog

mus rau uniformity ntawm cov khoom siv hlau.

Nyob ntawm lawv cov tshuaj muaj pes tsawg leeg thiab tshwj xeeb

cov khoom, cov hlua khi hlua khi tau yoog rau kev sib txuas

cov txheej txheem xaiv thiab tsis siv neeg sib txuas tshuab li

nrog rau ntau yam kev sib tw hauv kev sib dhos technologies.

Heraeus Electronics muaj ntau yam khoom lag luam

rau ntau yam kev siv ntawm cov

Automotive kev lag luam

Kev sib txuas lus

Semiconductor manufacturers

Kev lag luam khoom siv

Heraeus Bonding Wire khoom pawg yog:

Bonding xov hlau rau daim ntawv thov nyob rau hauv yas ntim

cov khoom siv hluav taws xob

Aluminium thiab aluminium alloy bonding hlau rau

daim ntawv thov uas yuav tsum tau ua qhov kub thiab txias

Copper bonding hlau raws li ib tug technical thiab

kev lag luam hloov pauv rau cov xov hlau kub

Precious thiab non-precious hlau bonding ribbons rau

hluav taws xob kev sib txuas nrog cov cheeb tsam loj.

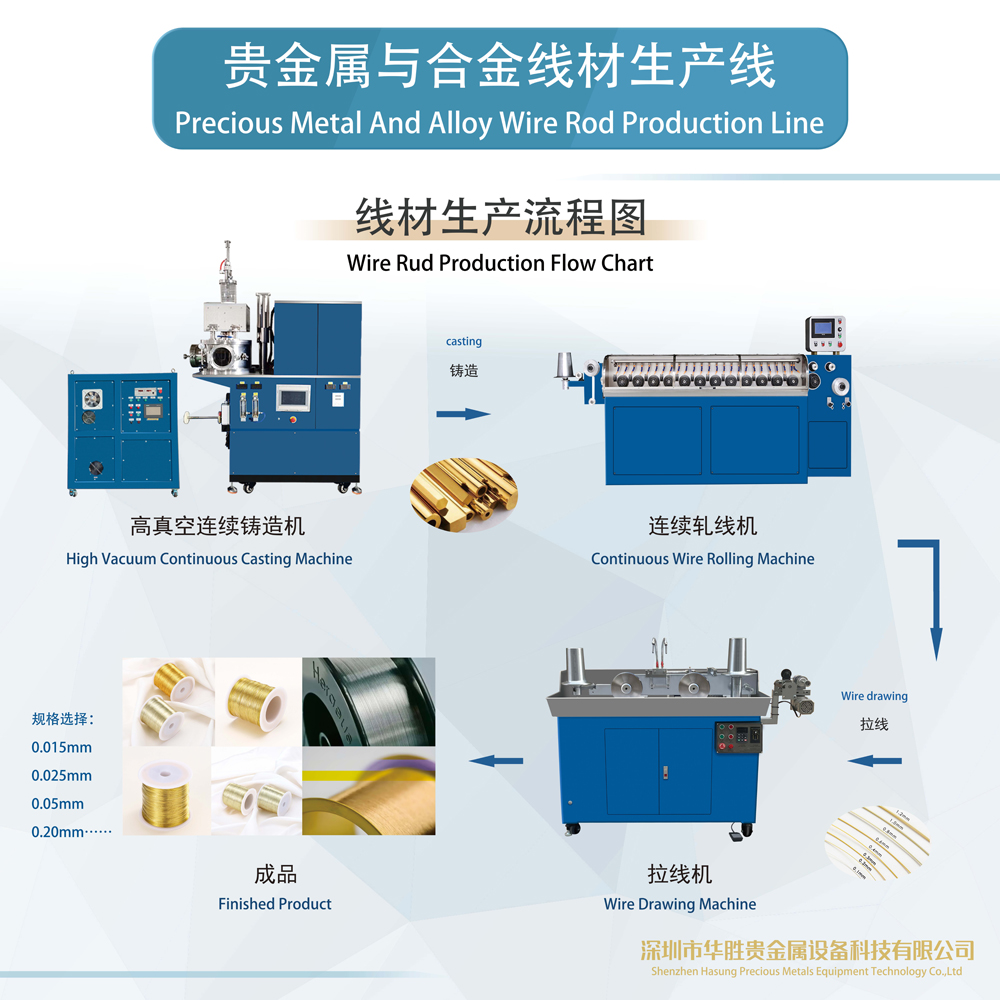

Bonding Wires Production Line

Post lub sij hawm: Lub Xya hli ntuj-22-2022