OEM Supply Dental Equipment Dental Lab Metal Medium Frequency Casting Tshuab / Induction Dental Lab Casting Tshuab

Peb ib txwm tsis tu ncua muab koj nrog qhov tseem ceeb tshaj plaws kev txhawb nqa cov neeg yuav khoom, nrog rau ntau yam kev tsim thiab qauv nrog cov khoom zoo tshaj plaws. Cov kev sim no suav nrog qhov muaj cov qauv tsim tshwj xeeb nrog kev ceev thiab xa mus rau OEM Khoom Siv Kho Hniav Dental Lab Hlau Nruab Nrab Zaus Casting Tshuab / Induction Dental Lab Casting Tshuab, Cov neeg siv khoom txaus siab yog peb lub hom phiaj tseem ceeb. Peb zoo siab tos txais koj los tsim kev lag luam kev sib raug zoo nrog peb. Yog xav paub ntxiv, nco ntsoov tias koj yuav tsis tos tiv tauj peb.

Peb ib txwm tsis tu ncua muab koj nrog qhov tseem ceeb tshaj plaws kev txhawb nqa cov neeg yuav khoom, nrog rau ntau yam kev tsim thiab qauv nrog cov khoom zoo tshaj plaws. Cov kev sim no suav nrog kev muaj cov qauv tsim kho nrog kev ceev thiab xa mus rauTuam Tshoj Medium Frequency Casting Tshuab thiab Induction Casting Tshuab Dental Equipment, Peb hwm peb tus kheej ua ib lub tuam txhab uas muaj cov pab pawg muaj zog ntawm cov kws tshaj lij uas muaj lub tswv yim tshiab thiab muaj kev paub zoo hauv kev lag luam thoob ntiaj teb, kev tsim kho kev lag luam thiab cov khoom lag luam nce qib. Ntxiv mus, lub tuam txhab nyob twj ywm tshwj xeeb ntawm nws cov neeg sib tw vim nws cov qauv zoo tshaj plaws hauv kev tsim khoom, thiab nws cov kev ua tau zoo thiab yooj yim hauv kev txhawb nqa kev lag luam.

Nta

Casting txoj kev

Cov txheej txheem casting li niaj zaus yog:

nplaim taws casting

induction casting

lub tshuab nqus tsev siab tuag-casting

nplaim taws casting

Nplaim Casting yog cov txheej txheem casting tshaj plaws thiab nws yog qhov ntau tshaj plaws thiab tsis tshua muaj nqi. Txoj kev no tau muaj txiaj ntsig zoo los tsim cov txheej txheem casting tab sis nws tsis haum rau kev cai lij choj thiab kev cai ntawm kev ua lag luam niaj hnub no. Cov txheej txheem no tsuas yog ua raws li tus neeg teb xov tooj lub peev xwm thiab kev txawj ntse: kev siv cov txheej txheem no yuav tsum muaj peev xwm tswj tau cov nplaim hluav taws, kev paub zoo ntawm kev ua haujlwm hlau thiab kev ua haujlwm zoo thiab kev ceev faj.Txawm hais tias muaj tseeb tias ntau tus neeg teb xov tooj yog tus tswv tiag tiag ntawm cov txheej txheem no peb. xav tias cov txheej txheem no yuav tsis lav kev rov tsim dua tshiab thiab qib zoo tas li. Thiab yog hais tias ib tug txheej txheem, xws li qhov no, yog kiag li raws li tus neeg teb xov tooj cov kev txawj thiab kev txawj ntse nws tsis yog ib tug saj zawg zog txheej txheem, thiab saj zawg zog yog ib qho tseem ceeb yuav tsum tau rau niaj hnub kho hniav technologies laboratories. Cov txheej txheem yuav tsum, qhov tseeb, yuav rov tsim dua txawm hais tias tus neeg ua haujlwm muaj peev xwm. Ntxiv rau qhov no, txoj kev nplaim hluav taws xob tsis tso cai rau cov ntawv pov thawj thiab cov ntaub ntawv ntawm cov txheej txheem casting los ntawm kev tswj cov txheej txheem tsis siv neeg.

Induction casting

Induction casting tau muaj tseeb sawv cev rau kev ua tiav hauv kev lag luam casting tab sis txawm tias qhov txheej txheem no muaj qee qhov nta uas ua rau nws tsis tuaj yeem siv nws hauv kev tsim nyog thiab kev teeb tsa hauv cov kws kho hniav hauv chav kuaj.The induction system yog semi-automatic hauv xwm thiab tag nrho. txheej txheem, zoo li nplaim taws casting, nyob ntawm tus neeg teb xov tooj qhov kev txawj ntse.Yog qhov tseeb tias tus neeg teb xov tooj muaj lub luag haujlwm los ntsuas seb puas yog melting lawm thiab kom qhib lub centrifugal ntaus ntawv. «Yog li ntawd, reproducibility thiab qhov zoo tsis tu ncua theem tsis tuaj yeem lav siv cov txheej txheem no.Induction casting yog ceev heev. Cov hlau alloy yog rhuab los ntawm sab hauv mus rau sab nraud. Cov txheej txheem txheej txheem ntawm induction system ua rau nws tsis yooj yim rau stabilize lub alloy kub lub sij hawm los yog los thaiv qhov kub thiab txias.Lub centrifugal siab yog unidirectional thiab ntau induction casting tshuab tsis feature lub tshuab nqus tsev vacuum, yog li cov huab cua nyob rau hauv lub chav tsev yuav ua rau. ib tug ntxeem tau casting.

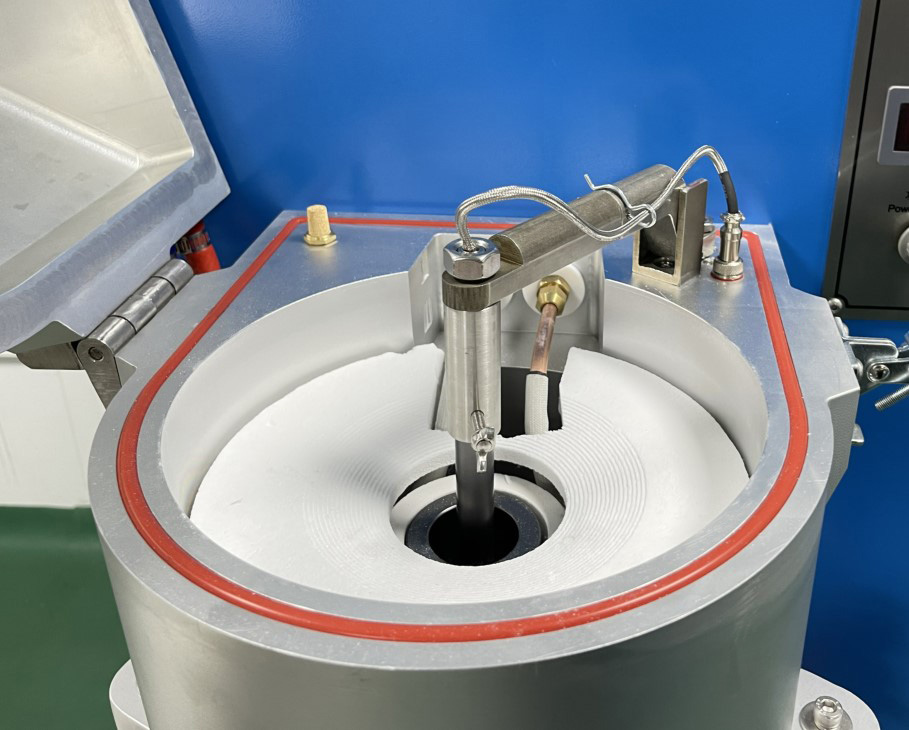

Lub tshuab nqus tsev siab tuag-casting

Lub tshuab nqus tsev siab tuag casting ib txwm tau suav tias yog cov txheej txheem zoo casting, txawm li cas los xij nws cov koob meej tseem txwv kom txog rau thaum nruab nrab-90s vim qhov tseeb tias qhov kub ntawm cov khoom siv no tsis haum rau melting thiab casting ntawm cov hniav hlau tshiab. Ib tiam tshiab ntawm cov khoom siv tau tsim tom qab, uas muaj peev xwm ntawm melting puag-hlau, semi-precious, Palladian thiab cov hniav nyiaj hniav kub muaj nuj nqis.

Hasung lub tshuab nqus tsev siab tuag-casting tshuab muaj qhov zoo tshaj plaws melting kub tswj, ua cov casting hauv lub tshuab nqus tsev thiab ua rau nws muaj peev xwm nqa tawm ntau txoj kev siab. Tag nrho cov no ua kom zoo siv tau yooj yim, rov tsim dua tshiab thiab zoo tas li thiab txo tus neeg teb xov tooj cuam tshuam rau qhov tshwm sim.

Yuav ua li cas mus cuag ib tug zoo casting

Ua raws li qhov xav tau ntawm qhov kub thiab txias

Kev tswj xyuas qhov kub ntawm casting yog qhov tseem ceeb tshaj plaws uas yuav tsum tau ua kom muaj cov yam ntxwv ntawm cov hlau metallurgy. Ua raws li cov ntaub ntawv pov thawj thiab cov cations tshwj xeeb yog qhov tseem ceeb kom tsis txhob muaj sublimation ntawm cov hlau uas tsis tshua muaj melting point uas muaj nyob hauv cov hlau.

Cov hlau molten ntawm qhov ntsuas kub uas tsim nyog yuav muaj tag nrho cov yam ntxwv ntawm lub tuam txhab tsim khoom, txwv tsis pub nws yuav muaj qee qhov kev hloov pauv hauv cov qauv ntawm cov hlau uas yuav ua rau muaj kev hloov pauv ntawm cov khoom siv thiab teeb meem thaum lub sijhawm ua haujlwm tom ntej.

Casting nrog omnidirectional siab

Kev kho hniav alloys yog tsim los ntawm ntau yam hlau sib txawv, txhua tus muaj nws tus kheej tshwj xeeb c ceev. Los ntawm kev siv cov txheej txheem centrifugal txhaj tshuaj, qhov tshwm sim yuav yog lub siab mono-directional nyob rau hauv uas cov hlau uas muaj siab dua c densities tau nkag rau hauv lub tog raj kheej ua ntej cov uas muaj qis dua. Siv cov txheej txheem siab tuag-casting, cov hlau yog qhia nyob rau hauv lub tog raj kheej thiab tom qab ntawd lub tog raj kheej raug rau omni-directional thiab lub siab tsis tu ncua uas tso cai rau cov txheej txheem zoo tag nrho ntawm cov hlau.

Nqus casting

Yuav kom ua tiav cov neeg kho tshuab ua haujlwm siab thiab raug qhov casting yuav tsum tau nqa tawm hauv qhov chaw tsis muaj cua. Qhov no ua kom muaj qhov tsis muaj qhov ntxeem tau ntawm alloy casting.

Qhov zoo ntawm Hasung tuag-casting system

Ua raws li qhov ntsuas kub tshwj xeeb cations

Qhov no ua tau ua tsaug rau lub kaw lus uas sib txuas nrog kev tswj hwm los ntawm microprocessor, thermocouple thiab tswj logic, nqa tawm nrog lub tshuab hluav taws xob nyuaj uas muaj qhov taw qhia infrared.

Qhov zoo: Qhov tseeb siab tshaj plaws hauv kev tsim cov hlau alloy nrog kev khaws cia ntawm metallurgic specifi cations.

Omnidirectional siab ntawm cov hlau

Tsis siv neeg compression tsim ib qho kev sib xws thiab txawm tias siab ntawm tag nrho lub tog raj kheej. Tsis muaj cov nyhuv centrifugal ntawm cov hlau uas tsim cov hlau.

Qhov zoo: siab dua alloy compactness, zoo txheej txheej, txuag ntawm cov khoom siv alloy (tsis tas yuav muaj cov khoom siv ntxiv los siv rau cov channel thiab cov khoom siv ntau dhau)

Melting yog ua nyob rau hauv ib qho chaw atmospheric

Tab sis casting yog nqa tawm nyob rau hauv ib tug airless ib puag ncig vim TVC series casting tshuab, ua ntej overturning, nqa tawm ib tug huab cua dawb ntau lawm txheej txheem tsis siv neeg.

Qhov zoo: Qhov tseeb tshaj plaws, ua haujlwm zoo thiab txuag lub sijhawm hauv kev ua tiav.

Kev ua haujlwm siab tshaj plaws

Kev siv tau los ntawm txhua qhov chaw kuaj mob rau tsis muaj kev cuam tshuam tib neeg.

Qhov zoo: Kev siv tau los ntawm txhua qhov chaw kuaj.

Kev tsim khoom zoo

Cov txheej txheem yog tsis siv neeg thiab nta tsis muaj kev cuam tshuam tib neeg.

Qhov zoo: Lub voj voog tsis siv neeg thiab tsis muaj kev cuam tshuam ntawm tib neeg tau txais txiaj ntsig zoo tshaj plaws ntawm cov txiaj ntsig.

Kev tswj tus nqi zoo

Kev tswj cov txheej txheem tag nrho yog 100% tus nqi siv tau: hluav taws xob siv hluav taws xob tsawg thiab cov khoom siv tau pheej yig.

Qhov zoo: kev siv nyiaj zoo.

Vim li cas koj thiaj xaiv Hasung Nqus Siab Casting Tshuab?

Hasung nqus tsev Casting tshuab piv rau lwm lub tuam txhab

1. Siv tus nqi siab ntiaj teb nto moo yam khoom los ntawm txawv teb chaws.

2. Kev ua haujlwm zoo heev los xyuas kom cov tshuab zoo.

3. Ntau qib zoo dua li lwm tus neeg muag khoom hauv Suav teb.

4. Cov txiaj ntsig zoo ntawm cov hlau casting.

5. Nrog kev vibration technology siab heev (yeem), kom paub tseeb tias cov hlau du Casted los ntawm Hasung lub siab casting tshuab.

TVC induction lub tshuab nqus tsev siab casting tshuab yog nruab nrog kev co uas tso cai rau koj kom muaj txiaj ntsig zoo dua, tshwj xeeb tshaj yog rau koj cov khoom nyias nyias, Karat kub jewellery.

Nrog Mitsubishi PLC kov vaj huam sib luag, yooj yim tab sis kev ua haujlwm zoo.

Koj tuaj yeem ua manually casting lossis tag nrho tsis siv neeg casting.

Koj tuaj yeem teeb tsa koj tus kheej raws li koj cov khoom nta.

Koj tuaj yeem teeb tsa cov khoom pov tseg los ntawm koj tus kheej.

Lub tshuab casting siv lub teb chaws Yelemees IGBT induction cua sov tshuab, Lub teb chaws Yelemees Schneider electrics, Lub teb chaws Yelemees Omron, Nyiv Mitsubishi electrics, Nyiv Panasonic pab tsav, Nyiv SMC, thiab lwm yam.

Siv cov khoom siv zoo, zoo craftmanship.

Technical Parameters

| Qauv No. | HS-TVC 1 | HS-TVC 2 | HS-TVC 4 | HS-TVC 6 | HS-TVC 8 |

| Qhov hluav taws xob | 220V ib theem / 380V 3 theem 50/60Hz | 380V 3 theem, 50/60Hz | |||

| Fais fab mov | 5 KW / 8 KW | 8 kWm | 15 KW | ||

| Max Temp | 1500 ° C | ||||

| Lub sij hawm yaj | 8-15 feeb. / 3-5 feeb. | 3-5 feeb. | 3-5 feeb | 3-5 feeb. | 4-6 feeb. |

| Tiv thaiv Gas | Argon / Nitrogen | ||||

| Siab | 0.1-0.3Mpa (Adjustable) | ||||

| Temp raug | ± 1 ° C | ||||

| Peev xwm (kub) | 1kg ua | 2kg ua | 4kg ua | 6kg ua | 8kg (kub) |

| Max. Flask loj | 4" x 10" / 5" x 12" | 5 "x 12" / 6.3 "x 12" | 6.3" x 12" po | 8.6 "x 12" / 10 "x 13" | |

| Lub tshuab nqus tsev twj | Lub tshuab nqus tsev zoo / lub tshuab nqus tsev German, nqus tsev kawm ntawv - 100KPA (yeem) | ||||

| Daim ntawv thov | Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys | ||||

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | ||||

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws | ||||

| Qhov ntev | 680 * 880 * 1530 hli | ||||

| Qhov hnyav | kwv yees. 150 kg | kwv yees. 150 kg | kwv yees. 160 kg | kwv yees. 180kg ib | kwv yees. 250 kg |

Khoom Qhia

Peb ib txwm tsis tu ncua muab koj nrog qhov tseem ceeb tshaj plaws kev txhawb nqa cov neeg yuav khoom, nrog rau ntau yam kev tsim thiab qauv nrog cov khoom zoo tshaj plaws. Cov kev sim no suav nrog qhov muaj cov qauv tsim tshwj xeeb nrog kev ceev thiab xa mus rau OEM Khoom Siv Kho Hniav Dental Lab Hlau Nruab Nrab Zaus Casting Tshuab / Induction Dental Lab Casting Tshuab, Cov neeg siv khoom txaus siab yog peb lub hom phiaj tseem ceeb. Peb zoo siab tos txais koj los tsim kev lag luam kev sib raug zoo nrog peb. Yog xav paub ntxiv, nco ntsoov tias koj yuav tsis tos tiv tauj peb.

Kev pab OEMTuam Tshoj Medium Frequency Casting Tshuab thiab Induction Casting Tshuab Dental Equipment, Peb hwm peb tus kheej ua ib lub tuam txhab uas muaj cov pab pawg muaj zog ntawm cov kws tshaj lij uas muaj lub tswv yim tshiab thiab muaj kev paub zoo hauv kev lag luam thoob ntiaj teb, kev tsim kho kev lag luam thiab cov khoom lag luam nce qib. Ntxiv mus, lub tuam txhab nyob twj ywm tshwj xeeb ntawm nws cov neeg sib tw vim nws cov qauv zoo tshaj plaws hauv kev tsim khoom, thiab nws cov kev ua tau zoo thiab yooj yim hauv kev txhawb nqa kev lag luam.

Lub tshuab nqus tsev siab casting tshuab consumables:

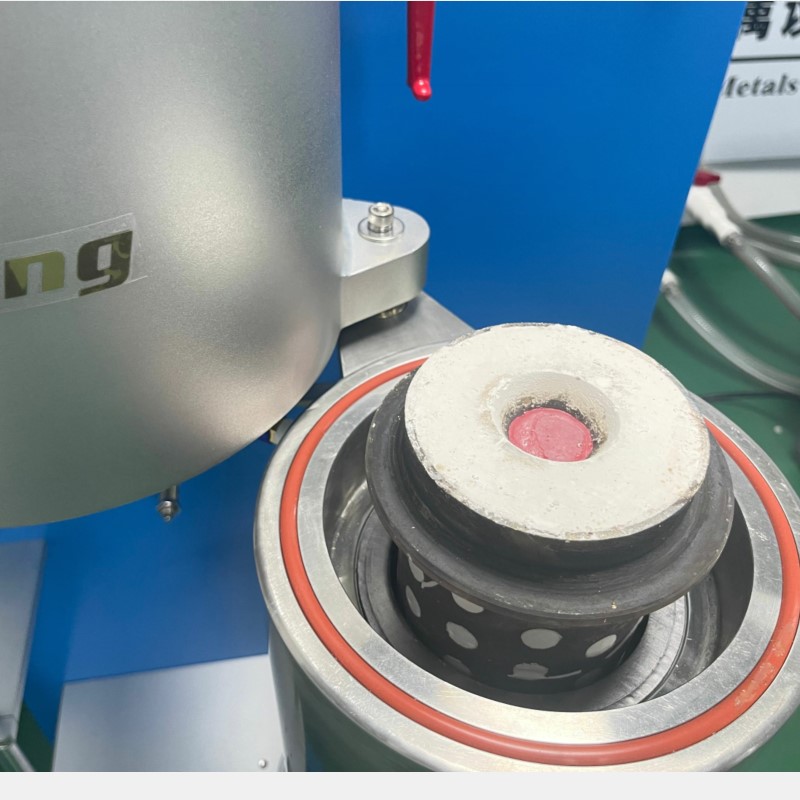

1. Graphite crucible

2. Ceramic gasket

3. Ceramic tsho

4. Graphite stopper

5. Thermocouple

6. Cua sov kauj

Tag nrho cov jewellery ntau lawm kab muaj xws li:

1. 3D tshuab luam ntawv

2. Vulcanizer

3. Wax injector

4. Lub qhov cub kub

5. Lub tshuab nqus tsev siab casting tshuab

6. Kev ntxuav

7. Polishing

Niaj hnub no, jewellery factories nyiam kom muaj tag nrho tsis siv neeg casting tshuab uas txuag tau ntau tus nqi zog thiab ua kom cov khoom ua tau zoo. Ntawm Hasung, peb muab koj tag nrho cov hniav nyiaj hniav kub casting kev daws teeb meem ntawm cov khoom zoo tshaj plaws los ntawm Tuam Tshoj.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

.png)