Kub Refining Tshuab: Cov tshuab tseem ceeb hauv cov txheej txheem kub refining

Kub tau ua lub cim ntawm kev nplua nuj thiab kev vam meej rau ntau pua xyoo, thiab nws cov txiaj ntsig tau ua rau nws nrhiav tau cov khoom lag luam thoob plaws txhua qhov chaw ntawm lub neej. Cov txheej txheem kub refining yog ib qho tseem ceeb los xyuas kom meej nws purity thiab zoo, thiab kub refineries ua lub luag haujlwm tseem ceeb hauv qhov no. Yuav kom ua tiav cov txheej txheem kub refining, ntau lub tshuab yuav tsum tau ua kom paub tseeb tias qhov ua tau zoo thiab qhov tseeb ntawm cov txheej txheem refining. Hauv tsab xov xwm no, peb yuav qhia txog cov cuab yeej siv yooj yim uas yuav tsum tau ua hauv lub tshuab ua kom kub, suav nrog kub flake ua tshuab, kub hmoov atomizers, kub refining tshuab, kub smelting furnaces, hlau granulator, thiab kub bar nqus casting, logo stamping tshuab, thiab lwm yam.

Kub flakes ua tshuab:

Thawj kauj ruam hauv cov txheej txheem kub refining yog kom tau txais cov kub hauv nws daim ntawv nyoos, feem ntau nyob rau hauv daim ntawv kub ore los yog kub nuggets. Txhawm rau pib cov txheej txheem refining, kub yuav tsum tau tawg mus rau hauv nyias flakes, ntau cov khoom tswj tau. Qhov no yog qhov uas tus tsim sequin tuaj rau hauv kev ua si. thiab nws yog ib qho yooj yim rau chemical soaking lub hom phiaj. Lub tshuab yog tsim los yaj thiab tau txais cov khoom siv kub kub rau hauv nyias kub alloy flakes, ua cov kub flakes uas tuaj yeem ua tiav ntxiv hauv kev ua kom zoo dua qub.

Kub hmoov atomizer:

Sib nrug los ntawm kub flakes, lwm qhov kev xaiv yog hloov cov ntaub ntawv raw rau hauv cov hmoov kub. Cov hmoov kub atomizer yog cov cuab yeej tseem ceeb hauv cov txheej txheem no, nws yog lub luag haujlwm rau hloov cov ntaub ntawv kub kub rau hauv cov hmoov (feem ntau yog 100 mesh loj) los ntawm cov txheej txheem atomization. Qhov no suav nrog ejecting molten kub mus rau hauv lub chamber uas nws solidifies rau hauv me me hais, ua cov hmoov zoo kub uas yog ib qho tseem ceeb rau lub tom ntej refining theem.

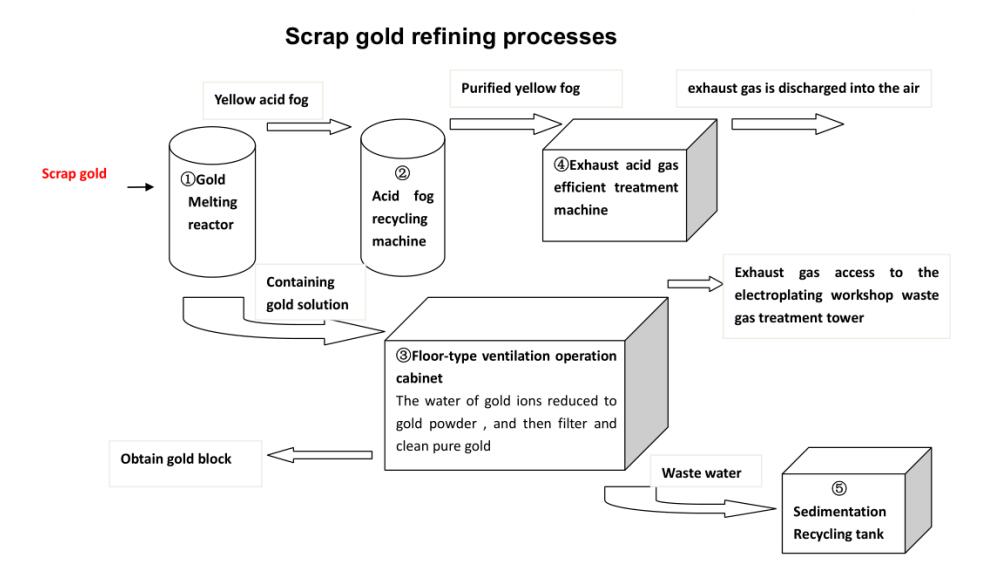

Kub refining system:

Nyob rau hauv lub plawv ntawm tej kub refinery yog kub refining system, uas yog lub luag hauj lwm rau purifying cov kub thiab tshem tawm tej impurities los yog tej yam kab mob. Lub kaw lus feem ntau muaj ntau yam khoom, nrog rau cov tshuaj tso tsheb hlau luam, cov ntxaij lim dej, thiab cov khoom siv sedimentation, txhua tus ua haujlwm ua ke kom cais cov kub ntshiab ntawm lwm cov hlau thiab impurities. Cov tshuab ua kom zoo siv cov txheej txheem tshuaj xws li aqua regia lossis electrolysis kom ua tiav qhov xav tau kub purity, ua kom nws ua tau raws li cov qauv kev lag luam rau kev lag luam siv. Feem ntau tus nqi ntawm cov kab ntau lawm nyob ntawm qhov muaj peev xwm ib hnub thov, lub kaw lus yuav tsim thiab nruab nrog lub peev xwm thov. Qhov kub refining system feem ntau suav nrog cov tshuaj tiv thaiv kab mob, kev sib cais, cov dej phwj tuaj kho, cov kav dej thiab cov pa luam yeeb, thiab lwm yam.

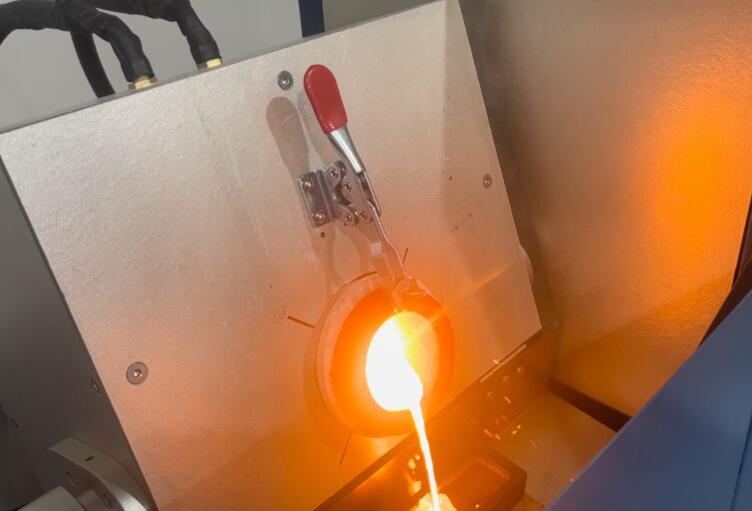

Kub melting rauv:

Txhawm rau ua cov txheej txheem ntxiv ntawm daim txhuam cev kub los ntawm kub refining, daim txhuam cev kub yuav tsum tau yaj mus rau hauv lub xeev molten. Qhov no yog qhov uas lub cub tawg kub los ua si. Lub cub tawg yog tsim los ua kom kub kub rau nws qhov melting point, ua kom yooj yim rau kev tswj thiab cais tawm ntawm cov impurities seem. Cov kub molten tuaj yeem muab nchuav rau hauv pwm los tsim cov khoom kub lossis lwm cov ntaub ntawv uas xav tau rau kev lag luam.

Hlau granulating tshuab:

Txhawm rau kom tau txais kev txhaj tshuaj kub zoo ib yam uas yooj yim thiab raug ntsuas los ntawm kev ntsuas qhov ntsuas thiab qhov tseeb qhov tseeb qhov hnyav ntawm lub hom phiaj kub, hlau granulator yog lub tshuab taw tes tseem ceeb los ua lub luag haujlwm. Qhuav kub thiab tau txais kub nplej los ntawm granulating tshuab. Nws muaj ob hom thaum ib qho yog gravity granulating tshuab, lwm yam yog nqus granulator.

Kub bar nqus tsev vacuum:

Tom qab kub yog refined thiab melted raws li kev txhaj tshuaj kub, nws yog feem ntau cam khwb cia rau hauv tej duab los yog cov ntaub ntawv kom nws yooj yim mus lis thiab thauj. Lub tshuab nqus tsev kub lub tshuab nqus tsev yog siv los ua kom tiav qhov no raws li nws raug muab molten kub rau hauv pwm hauv lub tshuab nqus tsev. Cov txheej txheem no ua kom ntseeg tau tias cov kub tuav tau tsim nrog kev ua haujlwm siab thiab ua tau zoo, npaj rau kev ua lag luam deals.

Logo stamping hydraulic xovxwm tshuab:

Feem ntau cov neeg muag khoom kub xav ua lawv tus kheej lub logo thiab lub npe ntawm cov kub tuav, yog li lub logo stamping tshuab ua haujlwm ci ntsa iab ntawm qhov no. Nrog ntau qhov sib txawv ntawm cov tuav thiab sib txawv tuag.

Dot peen npav system:

Lub kub bar feem ntau yog nrog nws tus kheej serial tooj xws li tus lej ID, yog li feem ntau cov neeg ua haujlwm kub siv dot peen marking system los kos cov lej cim ntawm txhua qhov kub ingot.

Nyob rau hauv cov ntsiab lus, ib tug kub refinery yuav tsum tau ib tug series ntawm cov tshuab tshwj xeeb los ua cov txheej txheem kub refining complex. Los ntawm kev rhuav tshem cov khoom kub kub rau hauv flakes, hloov mus rau hauv cov hmoov zoo, thiab thaum kawg purifying thiab nrum nws mus rau hauv cov duab uas xav tau, txhua lub tshuab ua lub luag haujlwm tseem ceeb hauv kev ua kom zoo thiab purity ntawm refined kub. Los ntawm kev nqis peev hauv cov tshuab thiab cov cuab yeej siv tau zoo, cov chaw tsim khoom kub tuaj yeem txhim kho kev ua haujlwm thiab tsim cov khoom kub zoo uas ua tau raws li kev xav tau ntawm kev lag luam.

Koj tuaj yeem tiv tauj Hasung rau tag nrho cov khoom siv no rau koj lub lag luam kub. Koj yuav tau txais cov tshuab zoo tshaj plaws nrog cov chaw tsim khoom qub nrog tus nqi zoo thiab cov kev pabcuam.

Post lub sij hawm: May-21-2024