Hasung T2 Jewelry Vacuum Pressure Casting Tshuab

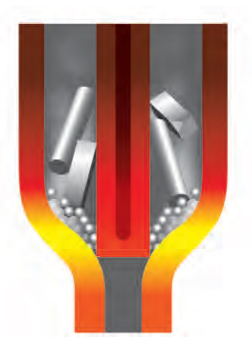

Vim li cas koj thiaj xaiv Hasung Nqus Siab Casting Tshuab?

Hasung T2 Nqus Casting Tshuab piv rau lwm lub tuam txhab

1. Precise casting kev ua tau zoo

2. Zoo melting ceev. Melting ceev yog nyob rau hauv 2-3 feeb.

3. Muaj zog casting siab.

4. Hasung cov khoom qub yog cov khoom muaj npe nrov hauv tsev, Nyiv thiab Germanu.

5. Precise casting kev ua tau zoo

6. Txhawb 100 txoj haujlwm nco

7. Kev txuag hluav taws xob. Nrog qis zog noj 10KW 380V 3 theem.

8. Siv nitrogen los yog argon nkaus xwb, tsis tas yuav txuas rau compressor cua.

Technical Parameters

| Qauv No. | HS-T2 |

| Qhov hluav taws xob | 380V, 50/60Hz, 3 theem |

| Fais fab mov | 10 KW |

| Max Temp | 1500 ° C |

| Lub sij hawm yaj | 2-3 feeb. |

| Kev Tiv Thaiv Gas | Argon / Nitrogen |

| Temp raug | ± 1 ° C |

| Peev xwm (kub) | 24K: 2.0Kg, 18K: 1.55Kg, 14K: 1.5Kg, 925Ag: 1.0Kg |

| Crucible Volume | 242cc ua |

| Qhov ntau thiab tsawg lub raj mis | 5" x 12" |

| Lub tshuab nqus tsev twj | Lub tshuab nqus tsev zoo |

| Daim ntawv thov | Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys |

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua tiav tag nrho cov txheej txheem casting |

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws |

| Qhov ntev | 800 * 600 * 1200 hli |

| Qhov hnyav | kwv yees. 230kg ua |

Khoom Qhia

Title: The Evolution of Gold Jewelry Casting Technology: From Ancient Techniques to Modern Innovations

Tau ntau pua xyoo, cov hniav nyiaj hniav kub kub tau ua lub cim ntawm kev nplua nuj, xwm txheej thiab kev zoo nkauj. Los ntawm ancient civilizations mus rau niaj hnub zam, lub ntxim nyiam ntawm kub tseem zoo li qub. Ib qho ntawm cov txheej txheem tseem ceeb hauv kev tsim cov hniav nyiaj hniav kub yog casting, uas tau hloov zuj zus mus rau lub sijhawm. Nyob rau hauv no blog, peb yuav tshawb txog cov fascinating taug kev ntawm kub hniav nyiaj hniav kub casting technology, los ntawm nws thaum ntxov txoj kev loj hlob mus rau niaj hnub kev txiav-ntug nrhav.

Ancient Technology: Yug ntawm Kub Casting

Cov keeb kwm ntawm kub casting tuaj yeem taug qab mus rau kev vam meej thaum ub xws li Egypt, Mesopotamia, thiab Tuam Tshoj. Cov craftsmen thaum ntxov tau tsim cov txheej txheem casting yooj yim siv cov pwm yooj yim ua los ntawm av nplaum, xuab zeb, lossis pob zeb. Cov txheej txheem cuam tshuam nrog cua kub kom txog thaum nws mus txog lub xeev molten thiab tom qab ntawd nchuav rau hauv cov pwm npaj los tsim cov hniav nyiaj hniav kub.

Thaum cov txheej txheem qub no tau ua tiav rau lawv lub sijhawm, lawv raug txwv hauv qhov raug thiab tsis yooj yim. Qhov tshwm sim cov hniav nyiaj hniav kub feem ntau muaj qhov ntxhib thiab nyoos, tsis muaj cov ntsiab lus zoo thiab cov qauv tsim sib txawv uas ua rau cov hniav nyiaj hniav kub niaj hnub.

Medieval Progress: Sawv Lost Wax Casting

Thaum lub sij hawm Nrab Hnub nyoog, kev nce qib loj hauv kev siv tshuab kub casting tau tshwm sim nrog kev txhim kho ntawm kev siv tshuab ploj ploj. Txoj kev no tau hloov pauv cov txheej txheem casting, tso cai rau cov neeg siv khoom tsim cov khoom siv ntau dua thiab cov ncauj lus kom ntxaws.

Cov txheej txheem wax ploj ploj yog tsim cov qauv siv quav ciab ntawm qhov xav tau cov hniav nyiaj hniav kub tsim, uas yog tom qab ntawd ntim rau hauv pwm ua los ntawm plaster lossis av nplaum. Cov pwm yog rhuab, ua rau cov wax yaj thiab evaporate, tawm hauv cov kab noj hniav nyob rau hauv cov duab ntawm tus thawj wax qauv. Molten kub tau muab nchuav rau hauv kab noj hniav, tsim kom muaj qhov tseeb thiab nthuav dav ntawm cov qauv siv quav ciab.

Cov thev naus laus zis no tau cim qhov kev vam meej loj hauv kev kos duab ntawm kev kos duab kub, tso cai rau cov neeg ua haujlwm tsim cov hniav nyiaj hniav kub nrog cov qauv zoo nkauj, ua haujlwm zoo filigree, thiab cov ntawv zoo nkauj uas yav tas los tsis tuaj yeem ua tiav.

Industrial kiv puag ncig: Mechanized Casting txheej txheem

Lub Industrial Revolution coj ib nthwv dej ntawm kev nce qib thev naus laus zis uas hloov pauv cov txheej txheem tsim khoom hauv ntau qhov kev lag luam, suav nrog kev tsim cov hniav nyiaj hniav kub. Nyob rau lub sijhawm no, cov txheej txheem casting tshuab tau qhia, tso cai rau cov khoom lag luam kub kub.

Ib qho ntawm cov kev hloov tshiab tseem ceeb yog kev txhim kho lub tshuab centrifugal casting, uas siv lub zog centrifugal kom sib npaug faib cov kub kub rau hauv pwm. Cov txheej txheem automated no ua rau muaj kev ua tau zoo thiab sib xws ntawm kub casting, uas ua rau cov zis ntau dua thiab ntau dua cov khoom siv nyiaj txiag.

Kev tsim kho tshiab niaj hnub: digital tsim thiab 3D luam ntawv

Nyob rau hauv xyoo tsis ntev los no, qhov tshwm sim ntawm digital tsim thiab 3D tshuab luam ntawv tau hloov cov toj roob hauv pes ntawm kub hniav nyiaj hniav kub casting. Cov kev hloov pauv tshiab no tau hloov pauv txoj kev tsim cov hniav nyiaj hniav kub tsim thiab txhais ua cov khoom siv lub cev.

Cov qauv tsim software tso cai rau cov neeg tsim khoom siv nyiaj txiag los tsim cov qauv 3D zoo nkauj nrog qhov tsis tau pom dua qhov tseeb thiab nthuav dav. Cov qauv digital no tuaj yeem hloov mus rau hauv lub cev qauv siv 3D luam ntawv thev naus laus zis, uas tsim cov hniav nyiaj hniav kub txheej los ntawm txheej siv ntau yam ntaub ntawv, suav nrog wax rau casting.

Kev siv 3D luam ntawv nyob rau hauv kub hniav nyiaj hniav kub casting qhib qhov tshiab possibilities rau tsim complex thiab customized designs uas yav tas los unachievable los ntawm tsoos casting txoj kev. Cov thev naus laus zis kuj tseem txhim kho cov qauv tsim thiab cov txheej txheem tsim khoom, txo cov sij hawm ua cov hmoov txhuas thiab ua kom nrawm dua ntawm kev tsim cov hniav nyiaj hniav kub.

Tsis tas li ntawd, kev nce qib hauv metallurgical thiab alloying thev naus laus zis tau ua kom yooj yim rau kev txhim kho cov kub kub tshiab nrog cov khoom zoo xws li kev ua kom muaj zog, ruaj khov, thiab xim hloov. Cov alloys tshiab no nthuav tawm cov kev muaj tswv yim zoo rau cov neeg tsim khoom thiab cov chaw tsim khoom, tso cai rau lawv thawb cov ciam teb ntawm cov tsoos kub hniav nyiaj hniav kub zoo nkauj.

Lub neej yav tom ntej ntawm kub hniav nyiaj hniav kub casting tshuab

Raws li thev naus laus zis txuas ntxiv mus, lub neej yav tom ntej ntawm cov hniav nyiaj hniav kub kub casting muaj qhov ua tau zoo dua. Cov thev naus laus zis tshiab xws li kev tsim khoom ntxiv thiab cov neeg ua haujlwm siab heev yuav tsum tau hloov kho cov txheej txheem casting ntxiv, coj cov qib tshiab ntawm precision, efficiency thiab customization.

Tsis tas li ntawd, kev sib koom ua ke kev txawj ntse thiab tshuab kev kawm algorithms rau hauv cov hniav nyiaj hniav kub tsim thiab kev ua haujlwm ntau lawm muaj peev xwm los txhim kho cov txheej txheem casting, txo cov khoom pov tseg, thiab txhim kho tag nrho cov khoom zoo ntawm cov hniav nyiaj hniav kub tiav.

Nyob rau hauv xaus, lub evolution ntawm kub hniav nyiaj hniav kub casting tshuab yog ib tug ua pov thawj rau lub ingenuity thiab innovation ntawm craftsmen thiab technicians thoob plaws hauv keeb kwm. Los ntawm cov txheej txheem qub ntawm kev ploj tuag casting mus rau niaj hnub marvels ntawm digital tsim thiab 3D luam ntawv, kos duab ntawm kub casting txuas ntxiv hloov zuj zus kom tau raws li qhov xav tau ntawm lub sijhawm hloov pauv.

Saib mus rau yav tom ntej, nws yog qhov tseeb tias kev sib xyaw ntawm cov tsoos craftsmanship thiab cov thev naus laus zis thev naus laus zis yuav txuas ntxiv tsim cov toj roob hauv pes ntawm cov hniav nyiaj hniav kub kub casting, muab qhov muaj peev xwm kawg rau kev muaj tswv yim, kho kom zoo thiab zoo hauv ntiaj teb cov hniav nyiaj hniav kub zoo.

Lub tshuab nqus tsev siab casting tshuab consumables:

1. Graphite crucible

2. Ceramic gasket

3. Ceramic tsho

4. Graphite stopper

5. Thermocouple

6. Cua sov kauj

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur