Compact me Me Metal Granulator Granulating Equipment for Gold Silver

Technical Parameters

| Qauv No. | HS-GS 2 | HS-GS 3 | HS-GS 4 | HS-GS 5 | HS-GS 6 | HS-GS 8 |

| Qhov hluav taws xob | 220V, 50/60Hz, Ib theem / 380V, 50/60Hz, 3 Phase | |||||

| Hwj chim | 8 kWm | 10 KW | 15 KW | |||

| Max Temp | 1500 ° C | |||||

| Peev xwm (kub) | 2kg ua | 3kg ua | 4kg ua | 5kg ua | 6kg ua | 8kg ua |

| Lub sij hawm yaj | 2-3 feeb. | 3-5 feeb. | ||||

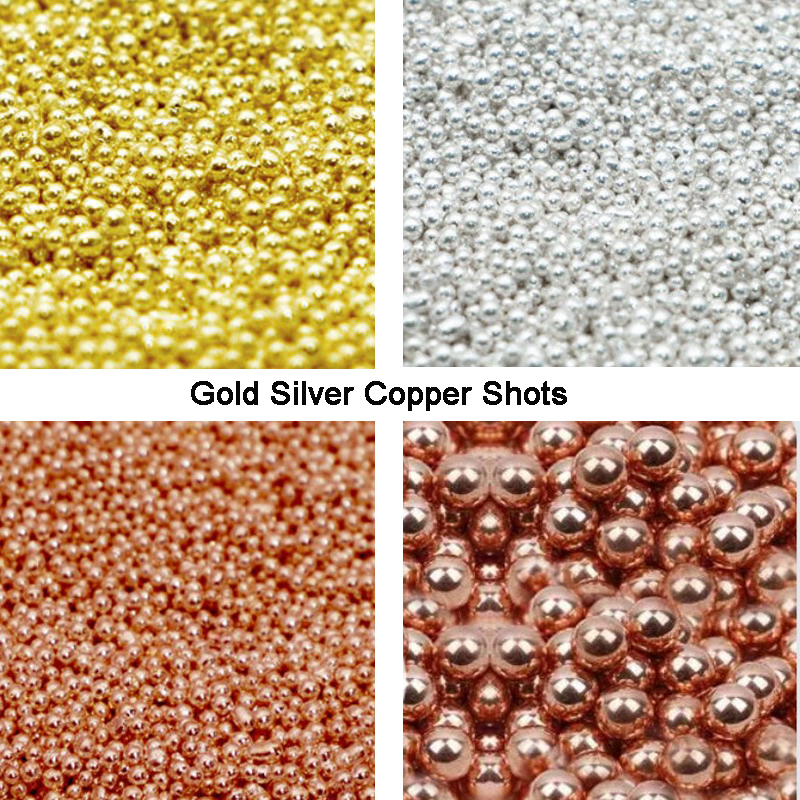

| Daim ntawv thov | Kub, K kub, nyiaj, tooj liab thiab lwm yam alloys | |||||

| Huab cua | Cua compressor | |||||

| Temp raug | ± 1 ° C | |||||

| Temp detector | Thermocouple | |||||

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws | |||||

| Qhov ntev | 1100 * 930 * 1240 hli | |||||

| Qhov hnyav | Kwv yees li. 180kg ib | Kwv yees li. 200 kg | ||||

Khoom Qhia

Title: Lub luag hauj lwm ntawm hlau granulator hauv cov txheej txheem kub refining

Kub refining yog cov txheej txheem zoo tib yam uas muaj ntau theem thiab cov cuab yeej siv los rho cov kub ntshiab los ntawm nws lub xeev nyoos. Ib qho ntawm cov khoom tseem ceeb hauv cov txheej txheem refining no yog cov hlau granulator. Nyob rau hauv no blog, peb yuav delve rau hauv lub luag hauj lwm ntawm ib tug hlau granulator nyob rau hauv kub refining thiab yuav ua li cas nws pab nyob rau hauv extracting ntshiab kub.

Dab tsi yog hlau granulator?

Ua ntej peb dhia mus rau hauv lub luag haujlwm ntawm cov hlau granulator hauv kub refining, cia peb xub nkag siab tias lub hlau granulator yog dab tsi thiab nws ua haujlwm li cas. Hlau granulator yog ib lub tshuab tsim los tsoo hlau seem rau hauv me me, sib npaug me me hais los yog granules. Nws yog feem ntau siv rau hauv cov khoom siv rov ua dua tshiab thiab kev tswj cov khib nyiab los ua cov khoom seem hlau thiab hloov mus rau hauv daim ntawv tswj tau ntau dua rau kev ua haujlwm ntxiv.

Lub luag haujlwm ntawm hlau granulator hauv kub refining

Nyob rau hauv kub refining, hlau granulator plays lub luag hauj lwm tseem ceeb nyob rau hauv thawj theem ntawm raw khoom ua. Nov yog nws txoj kev koom tes rau tag nrho cov txheej txheem refining:

1. Txo cov hlau seem

Thaum lub sij hawm kub refining txheej txheem, ntau hom hlau pov tseg yog tsim, nrog rau cov khoom seem, hluav taws xob pov tseg thiab lwm yam khoom siv hlau. Cov ntaub ntawv no yuav tsum tau txo qhov loj me los pab txhawb kev ua haujlwm ntxiv. Qhov no yog qhov uas hlau granulators tuaj ua si. Nws zoo crushes thiab pellets hlau seem, tsim kom muaj kev tswj xyuas ntau dua rau cov kauj ruam tom ntej refining.

2. Kev sib cais ntawm cov khoom tsis yog kub

Thaum cov hlau seem yog granulated, cov kauj ruam tom ntej hauv cov txheej txheem kub refining yog cais cov ntaub ntawv tsis kub los ntawm cov khoom siv kub. Cov hlau granular tau dhau los ua cov txheej txheem sib cais ntxiv xws li kev sib nqus sib nqus thiab kev sib cais ntawm qhov ntom ntom kom cais cov khoom kub uas muaj cov khoom seem ntawm cov hlau pov tseg. Qhov loj me thiab cov duab ntawm cov hlau granular pab txhawb cov txheej txheem kev sib cais, ua rau cov txheej txheem ua haujlwm zoo dua.

3. Txhim kho qhov chaw nto rau kev ua tshuaj lom neeg

Tom qab cov ntaub ntawv uas tsis yog kub sib cais, cov granular kub-muaj cov khoom yog tshuaj kho kom rho tawm cov kub ntshiab. Cov khoom siv particle daim ntawv muab thaj tsam loj dua, tso cai rau cov tshuaj nkag mus thiab ua rau cov khoom kub zoo dua. Qhov no ua rau cov extraction efficiency ntau dua thiab ua kom zoo dua cov txheej txheem.

4. Txhim kho cov txheej txheem smelting thiab casting

Thaum cov kub tau muab rho tawm los ntawm cov khoom siv granular, nws tau ua tiav ntxiv los ntawm melting thiab casting los ua kub ingots lossis lwm yam duab uas xav tau. Daim ntawv granular ntawm kub ua rau cov txheej txheem melting vim nws heats thiab melts cov khoom ntau tusyees. Qhov no tsim cov khoom kub zoo nrog cov qib zoo sib xws ntawm purity.

Zuag qhia tag nrho, hlau granulators ua lub luag haujlwm tseem ceeb hauv thawj theem ntawm kev ua kom zoo nkauj kub los ntawm kev npaj cov khoom siv raw rau kev ua haujlwm ntxiv, txhawb kev sib cais ntawm cov ntaub ntawv tsis kub, ua rau thaj chaw zoo rau kev ua tshuaj, thiab txhim kho cov txheej txheem smelting thiab casting.

Qhov tseem ceeb ntawm cov txheej txheem kub refining zoo

Cov txheej txheem kub ua kom zoo yog qhov tseem ceeb los xyuas kom meej qhov purity thiab zoo ntawm cov khoom kub kawg. Txawm hais tias siv rau kev tsim cov hniav nyiaj hniav kub, kev nqis peev, lossis kev siv lag luam, cov kub ntshiab yog qhov muaj nuj nqis heev thiab nrhiav tom qab. Yog li ntawd, lub luag hauj lwm ntawm cov khoom xws li hlau pelletizers nyob rau hauv refining kub mus rau qhov yuav tsum tau purity thiab zoo yuav tsis overstated.

Ntxiv nrog rau cov txheej txheem kev ua haujlwm, cov txheej txheem kub ua kom zoo kuj ua rau muaj kev ruaj ntseg ib puag ncig. Los ntawm kev tswj hwm thiab ua cov khoom pov tseg hlau zoo, suav nrog cov khoom pov tseg hluav taws xob thiab cov khoom seem, kev lag luam refining tuaj yeem txo qhov cuam tshuam ib puag ncig ntawm kev khawb kub thiab ua rau muaj kev tswj xyuas cov peev txheej ruaj khov.

nyob rau hauv xaus

Hauv cov ntsiab lus, hlau granulators ua lub luag haujlwm tseem ceeb hauv cov txheej txheem kub refining, suav nrog kev npaj cov khoom siv raw, ua kom muaj kev sib cais zoo, txhim kho kev kho tshuaj, thiab txhim kho cov txheej txheem smelting thiab casting. Nws txoj kev koom tes rau tag nrho cov efficiency thiab zoo ntawm kub refining yuav tsis raug ignored. Raws li qhov kev thov rau cov kub ntshiab tseem loj tuaj, cov txheej txheem ua kom zoo dua qub, kev txhawb nqa los ntawm cov cuab yeej siv qib siab xws li hlau granulators, tau dhau los ua qhov tseem ceeb ntxiv kom ua tau raws li kev lag luam xav tau rau cov khoom kub zoo.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur