Tus nqi pheej yig Tuam Tshoj Kub Bullion thiab Kub Ingot Rapid Prototyping Tshuab

Peb ntseeg hais tias lub sij hawm ncua sij hawm kev koom tes yuav ua tau ib tug tshwm sim ntawm zoo, tsim nyog ntxiv kev pab cuam, nplua nuj kev paub thiab tus kheej kev tiv tauj rau tus nqi pheej yig Tuam Tshoj kub Bullion thiab kub Ingot Rapid Prototyping Tshuab, Peb lub tuam txhab twb tsim ib tug kev paub, muaj tswv yim thiab lub luag hauj lwm pab pawg neeg. tsim cov neeg siv khoom thaum siv ntau txoj cai.

Peb ntseeg hais tias kev koom tes nrog lub sijhawm ntev tuaj yeem ua rau muaj txiaj ntsig zoo, tsim nyog ntxiv kev pabcuam, kev paub nplua nuj thiab kev sib cuag rau tus kheej.Tshuab Casting, Tuam Tshoj Rapid Prototyping Tshuab, Peb tau ua koj tus khub txhim khu kev qha hauv kev lag luam thoob ntiaj teb ntawm peb cov khoom. Peb tsom mus rau kev muab kev pabcuam rau peb cov neeg siv khoom raws li lub hauv paus tseem ceeb hauv kev ntxiv dag zog rau peb txoj kev sib raug zoo mus ntev. Qhov tsis tu ncua ntawm cov khoom lag luam qib siab ua ke nrog peb cov kev pabcuam ua ntej thiab tom qab muag zoo ua kom muaj kev sib tw muaj zog hauv kev lag luam thoob ntiaj teb. Peb txaus siab koom tes nrog cov phooj ywg ua lag luam hauv tsev thiab txawv teb chaws, los tsim lub neej yav tom ntej zoo. Txais tos tuaj xyuas peb lub Hoobkas. tos ntsoov yuav muaj kev koom tes nrog koj.

Nta

1. Ntse Nqus Kub Bar Casting:

1). Nias ib tus yuam sij- Tsis siv neeg kaw lub hau- Tsis siv neeg casting thiab txias- Tsis siv neeg qhib lub hau-

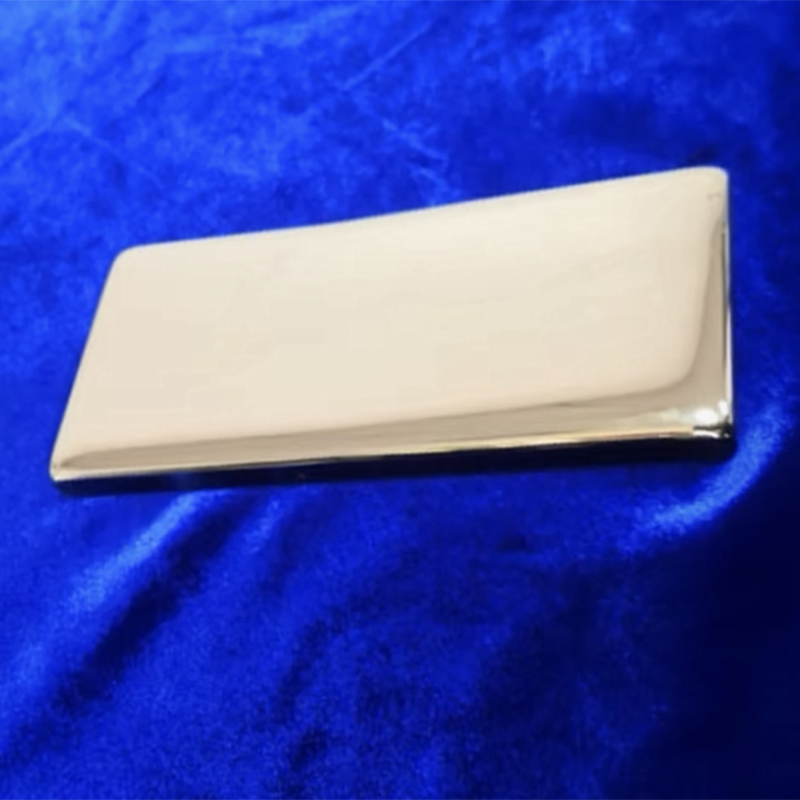

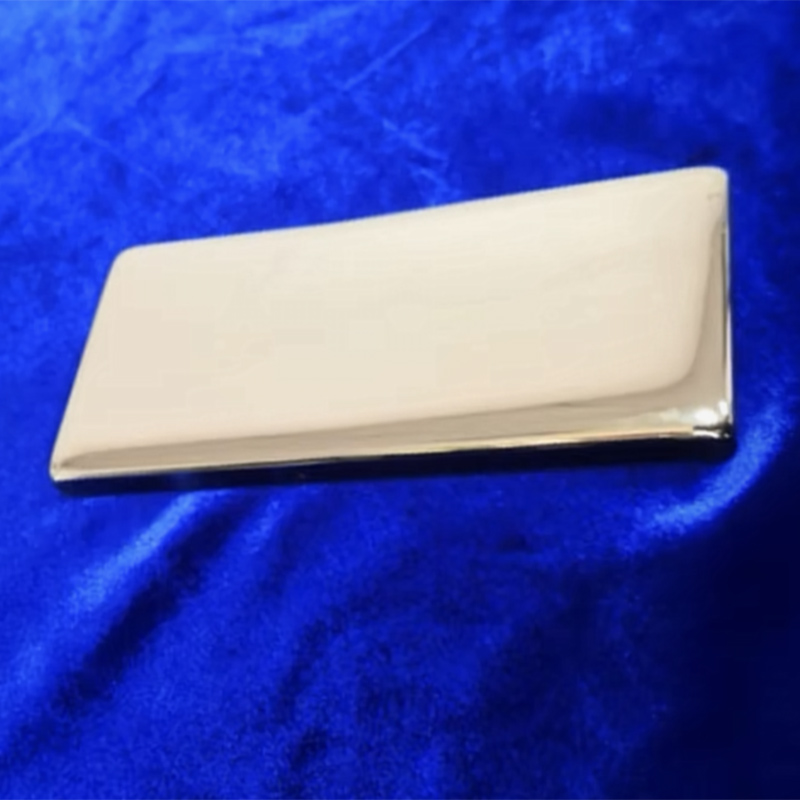

2) Tshem tawm qhov ci ntsa iab kub

2.Operation method: Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system.

3. Tswj system: Mitsubishi PLC + Tib neeg-tshuab interface ntse tswj system (yeem).

4. Siv German high-frequency cua sov tshuab, tsis siv neeg zaus mus txog qhovtwg thiab ntau yam kev tiv thaiv technologies, nws yuav yaj nyob rau hauv ib tug luv luv lub sij hawm, lub zog txuag, thiab ua hauj lwm efficiency.

5. Cov hom kaw / channel hom + lub tshuab nqus tsev / inert roj tiv thaiv lub tshuab melting chamber tuaj yeem tiv thaiv oxidation ntawm molten raw khoom thiab kev sib xyaw ntawm impurities. Cov khoom siv no yog tsim rau cov khoom siv high-purity hlau los yog cov hlau hlau uas yooj yim oxidized.

6. Txais kaw / channel hom + lub tshuab nqus tsev / inert gas los tiv thaiv lub melting chamber, melting thiab txias yog ua nyob rau tib lub sij hawm, lub sij hawm yog halved thiab ntau lawm efficiency yog nce.

7. Melting nyob rau hauv ib tug inert gas ib puag ncig, oxidation poob ntawm cov pa roj carbon pwm yog yuav luag negligible.

8. Nrog rau electromagnetic stirring muaj nuj nqi nyob rau hauv kev tiv thaiv ntawm inert gas, tsis muaj segregation nyob rau hauv cov xim.

9. Nws txais kev pov thawj yuam kev (tiv thaiv kev ruam) tsis siv neeg tswj qhov system, uas yooj yim dua rau kev siv.

10. Siv PID kub tswj qhov system, qhov kub thiab txias yog qhov tseeb dua (± 1 ° C).

11. HS-GV4, HS-GV15 HS-GV30 kub thiab nyiaj ingot forming khoom / puv-automatic ntau lawm kab yog nws tus kheej tsim thiab manufactured nrog advanced cov khoom theem rau smelting thiab casting kub, nyiaj, tooj liab thiab lwm yam alloys.

12. Cov khoom siv casting no siv Mitsubishi PLC kev tswj qhov system, SMC pneumatic thiab Panasonic servo tsav tsav thiab lwm yam khoom siv hauv tsev thiab txawv teb chaws.

13. Melting, electromagnetic stirring, thiab tub yees nyob rau hauv ib tug kaw / channel + lub tshuab nqus tsev / inert gas tiv thaiv melting chav tsev, kom cov khoom muaj cov yam ntxwv ntawm tsis muaj oxidation, tsawg poob, tsis muaj porosity, tsis muaj segregation nyob rau hauv cov xim, thiab zoo nkauj tsos.

Technical Parameters

| Qauv No. | HS-GV 4 | HS-GV 15 | HS-GV 30 | ||

| Tsis Siv Neeg Qhib Npog Kub Bar VacuumTshuab Casting | |||||

| Fais fab mov | 380V, 50/60Hz | ||||

| Lub zog nkag | 60 kWm | 60 kWm | 80 KW TSI | ||

| Max Temp | 1600 ° C | ||||

| Overal Casting Sijhawm | 10-12 mins. | 12-15 feeb. | 15-20 feeb. | ||

| Tiv thaiv Gas | Argon / Nitrogen | ||||

| Kub qhov tseeb | ± 1 ° C | ||||

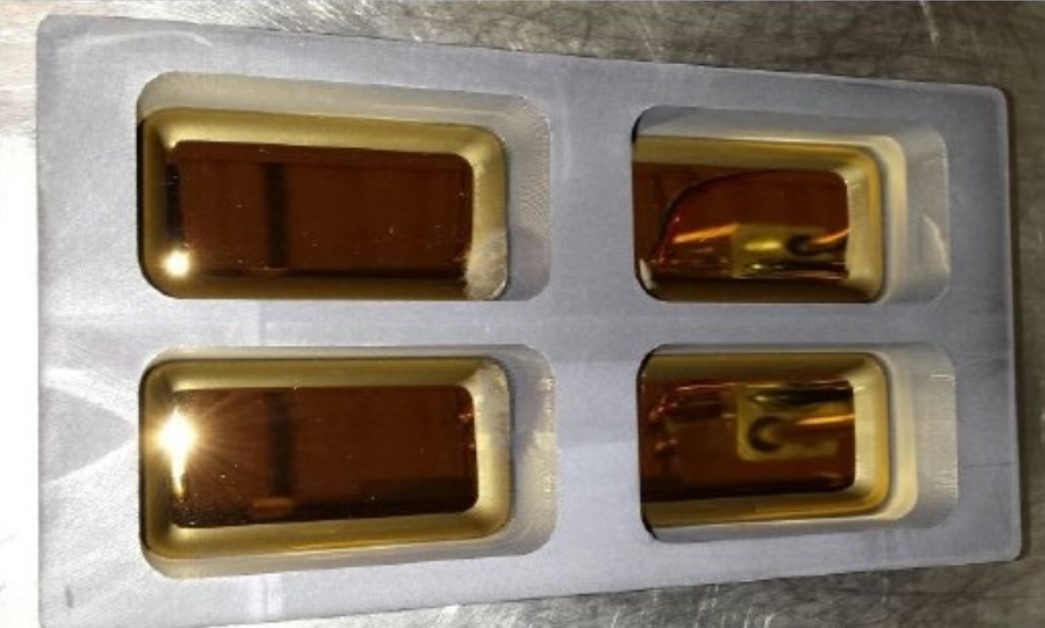

| Muaj peev xwm | 4kg: 4 pcs 1kg, 8pcs 0.5kg lossis ntau dua. | 15kg: 1pcs 15kg, lossis 5pcs 2kg lossis ntau dua | 30kg: 1pcs 30kg, lossis 2pcs 15kg lossis ntau dua | ||

| Daim ntawv thov | Kub, Nyiaj, Platinum, Palladium (Thaum los ntawm Pt, Pd, customized) | ||||

| Lub tshuab nqus tsev twj | Lub tshuab nqus tsev zoo / Lub tshuab nqus tsev German, Lub tshuab nqus tsev kawm qib-100KPA | ||||

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | ||||

| Tswj qhov system | Mitsubishi PLC + Tib neeg-tshuab interface ntse tswj qhov system (yeem) | ||||

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws | ||||

| Qhov ntev | 1150x680x1060mm | 1150x680x1060mm | 1250x680x1060mm | ||

| Qhov hnyav | 350 KG | 360 KG | 400 KG | ||

Khoom Qhia

Peb ntseeg hais tias lub sij hawm ncua sij hawm kev koom tes yuav ua tau zoo, tsim nyog ntxiv kev pab cuam, nplua nuj kev paub thiab tus kheej kev tiv tauj rau tus nqi pheej yig Tuam Tshoj kub Bullion thiab kub Ingot Rapid Prototyping Tshuab (CXM-GT / PT), Peb lub tuam txhab twb tsim ib tug. kev paub txog, muaj tswv yim thiab lub luag haujlwm pab pawg los tsim cov neeg siv khoom thaum siv ntau txoj cai yeej.

Tus nqi pheej yigTuam Tshoj Rapid Prototyping Tshuab, Tshuab Casting, Peb tau ua koj tus khub txhim khu kev qha hauv kev lag luam thoob ntiaj teb ntawm peb cov khoom. Peb tsom mus rau kev muab kev pabcuam rau peb cov neeg siv khoom raws li lub hauv paus tseem ceeb hauv kev ntxiv dag zog rau peb txoj kev sib raug zoo mus ntev. Qhov tsis tu ncua ntawm cov khoom lag luam qib siab ua ke nrog peb cov kev pabcuam ua ntej thiab tom qab muag zoo ua kom muaj kev sib tw muaj zog hauv kev lag luam thoob ntiaj teb. Peb txaus siab koom tes nrog cov phooj ywg ua lag luam hauv tsev thiab txawv teb chaws, los tsim lub neej yav tom ntej zoo. Txais tos tuaj xyuas peb lub Hoobkas. tos ntsoov yuav muaj kev koom tes nrog koj.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur