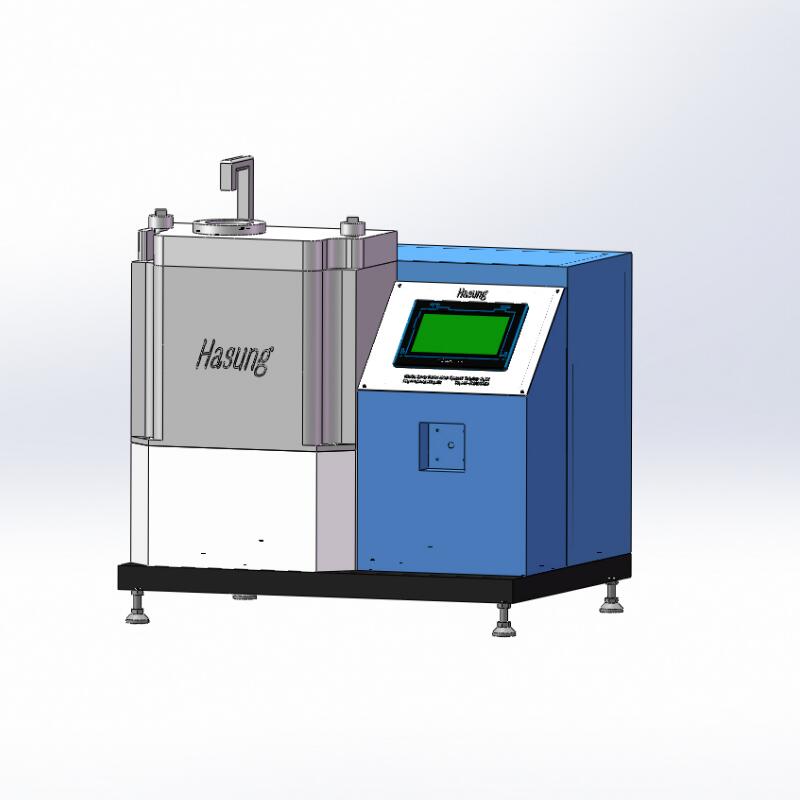

4 Bars 1kg Tsis Siv Neeg Kub Bar Ua Tshuab Hasung

Technical Parameters

| Qauv No. | HS-GV 4 | HS-GV 15 | HS-GV 30 | ||

| Tsis Siv Neeg Qhib Npog Kub Bar Nqus Casting Tshuab | |||||

| Fais fab mov | 380V, 50/60Hz | ||||

| Lub zog nkag | 50 kWm | 60 kWm | 70 kWm | ||

| Max Temp | 1500 ° C | ||||

| Overal Casting Sijhawm | 10-12 mins. | 12-15 feeb. | 15-20 feeb. | ||

| Tiv thaiv Gas | Argon / Nitrogen | ||||

| Program rau txawv tuav | Muaj | ||||

| Muaj peev xwm | 4kg: 4 pcs 1kg, 8pcs 0.5kg lossis ntau dua. | 15kg: 1pcs 15kg, lossis 5pcs 2kg lossis ntau dua | 30kg: 1pcs 30kg, lossis 2pcs 15kg lossis ntau dua | ||

| Daim ntawv thov | Kub, Nyiaj, Platinum, Palladium (Thaum los ntawm Pt, Pd, customized) | ||||

| Lub tshuab nqus tsev twj | Lub tshuab nqus tsev zoo (nrog) | ||||

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | ||||

| Tswj qhov system | 10" Weinview / Siemens PLC + Tib neeg-tshuab interface ntse tswj qhov system (yeem) | ||||

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws | ||||

| Qhov ntev | 1460 * 720 * 1010 hli | 1460 * 720 * 1010 hli | 1530x730x1150mm | ||

| Qhov hnyav | 300 KG | 300 KG | 400 KG | ||

Taw qhia rau Hasung Kub Bar Nqus Casting Tshuab - Qhov kawg daws rau Cov Khoom Kub thiab Nyiaj Kub Zoo

Puas yog koj tab tom nrhiav kev txhim khu kev qha, muaj txiaj ntsig zoo rau kev tsim cov khoom kub thiab nyiaj zoo? Kub bar nqus tsev casting tshuab yog koj xaiv zoo tshaj. Cov cuab yeej siv niaj hnub no yog tsim los ua kom tau raws li qhov xav tau ntawm ob tus neeg pib tshiab thiab cov kws tshaj lij hauv kev lag luam hlau muaj txiaj ntsig. Nrog nws cov kev ua haujlwm tsis siv neeg tag nrho thiab muaj peev xwm ua kom nrawm nrawm, lub tshuab no yog qhov kev xaiv zoo tshaj plaws rau cov uas tab tom nrhiav rau cov txiaj ntsig zoo nrog kev yooj yim thiab raug.

Kub bar lub tshuab nqus tsev casting tshuab yog tsim los nrog cov cuab yeej tshiab tshaj plaws los muab cov kev paub zoo thiab cov neeg siv khoom zoo. Nws tag nrho tsis siv neeg ua haujlwm ua rau nws zoo tagnrho rau cov pib tshiab uas nyuam qhuav pib hauv kev lag luam. Intuitive tswj thiab yooj yim-rau-ua raws cov lus qhia xyuas kom meej tias txawm tias cov neeg uas muaj kev txwv tsis pub muaj peev xwm khiav lub tshuab nrog kev ntseeg siab thiab ua tiav cov txiaj ntsig zoo.

Ib qho ntawm cov yam ntxwv zoo tshaj plaws ntawm lub tshuab nqus tsev kub casting yog lawv lub peev xwm los tsim cov kub kub thiab nyiaj kub zoo tshaj plaws. Txawm hais tias koj xav tsim kev nqis peev-qib kub thiab nyiaj los yog cov khoom zoo nkauj, lub tshuab no muab cov txiaj ntsig zoo tshaj plaws txhua lub sijhawm. Precision engineering thiab advanced tshuab nqus tsev casting tshuab xyuas kom meej tias cov tuav uas tsim tawm tsis muaj impurities thiab tsis xws luag thiab ua tau raws li cov qauv nruj tshaj plaws.

Ntxiv nrog rau nws cov txiaj ntsig zoo tshaj plaws, kub bar nqus tsev casting tshuab kuj paub txog lawv lub peev xwm melting sai. Hauv kev lag luam hlau muaj txiaj ntsig, lub sijhawm yog qhov tseem ceeb thiab lub tshuab no yog tsim los ua kom cov txheej txheem ntau lawm. Nrog rau lub sijhawm yaj nrawm, koj tuaj yeem ua kom cov khoom tsim tau zoo thiab ua tau raws li qhov xav tau ntawm kev lag luam nrawm yam tsis muaj kev cuam tshuam qhov zoo ntawm cov khoom kawg.

Tsis tas li ntawd, kub lub tshuab nqus tsev casting tshuab yog tsim los kom kav ntev thiab tsom rau kev ua haujlwm ntev thiab kev ntseeg tau. Nws cov khoom siv ruaj khov thiab cov ntaub ntawv zoo kom ntseeg tau tias nws tuaj yeem tiv taus qhov kev siv tsis tu ncua, ua rau nws muaj peev xwm ntse rau koj txoj kev lag luam. Nrog rau kev saib xyuas kom raug, lub tshuab no yuav txuas ntxiv muab kev ua tau zoo rau xyoo tom ntej, muab kev txhim khu kev qha, muaj txiaj ntsig zoo rau koj.

Txawm hais tias koj yog ib tus kws tsim khoom me me lossis cov chaw tsim khoom loj, lub tshuab nqus tsev kub kub muab qhov sib npaug zoo tshaj plaws ntawm precision, ceev thiab yooj yim ntawm kev siv. Nws versatility ua rau nws haum rau ntau yam kev siv, los ntawm kev tsim cov kev cai tsim kub tuav mus rau huab hwm coj tsim cov qauv kub. Txawm hais tias koj xav tau ntau npaum li cas, lub tshuab no tuaj yeem ua tau raws li koj xav tau.

Tag nrho cov nyob rau hauv tag nrho, kub bar nqus tsev casting tshuab yog qhov kawg daws rau cov neeg uas nrhiav los tsim high-zoo kub thiab nyiaj tuav tau yooj yim thiab zoo. Nws cov kev ua haujlwm siab ua haujlwm siab, muaj peev xwm ua kom nrawm nrawm thiab cov khoom tsim tawm tsis zoo ua rau nws muaj txiaj ntsig zoo rau txhua lub lag luam hauv kev lag luam hlau muaj nuj nqis. Kev nqis peev hauv lub tshuab txiav-ntug no coj koj lub peev xwm tsim khoom mus rau qhov siab tshiab. Kev paub qhov txawv ntawm lub tshuab nqus tsev kub lub tshuab nqus tsev tuaj yeem nqa tuaj rau koj lub lag luam.

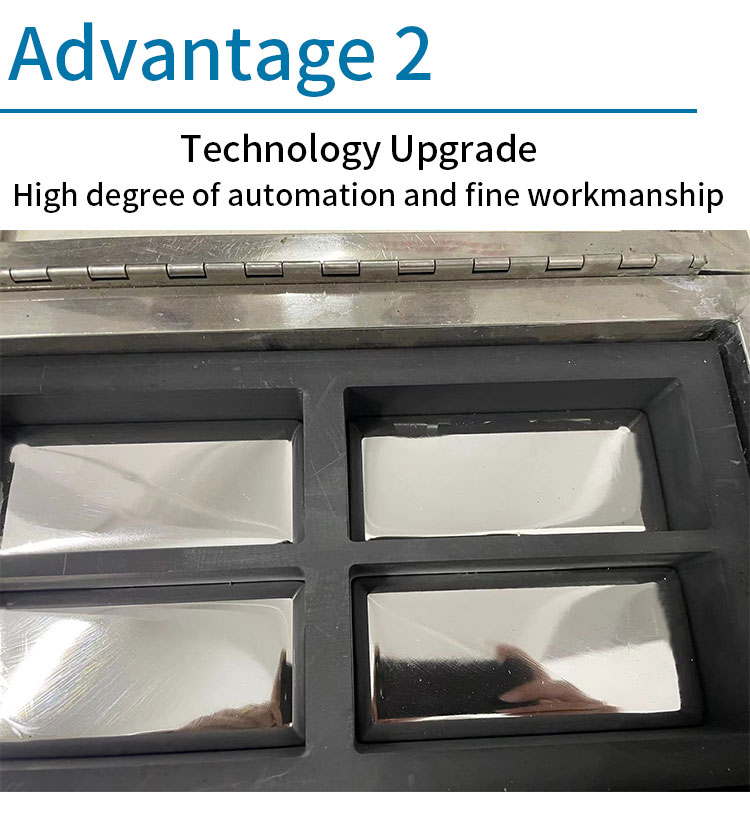

Khoom Qhia

Title: Cov txheej txheem nyuaj ntawm kev ua kom zoo nkauj kub thiab ingot casting hauv kev lag luam

Nyob rau hauv lub ntiaj teb no ntawm precious hlau, kub tuav ib tug tshwj xeeb qhov chaw. Nws qhov kev nyiam thiab tus nqi tau ua rau nws yog cov khoom lag luam nrhiav tau ntau pua xyoo, thiab kev lag luam kub refining ua lub luag haujlwm tseem ceeb hauv kev ua kom cov kub uas peb siv hauv jewellery, electronics thiab kev nqis peev ua tau raws li cov qauv siab tshaj plaws ntawm purity thiab zoo. Ib qho tseem ceeb ntawm kev lag luam yog cov txheej txheem kub ingot casting, uas hloov cov kub ua kom zoo rau hauv cov khoom kub kub uas cim kev nplua nuj thiab kev vam meej. Nyob rau hauv no blog, peb yuav delve rau hauv cov txheej txheem complex ntawm refining thiab casting kub, nthuav qhia cov ncauj lus kom ntxaws kauj ruam muab kev koom tes thiab qhov tseem ceeb ntawm cov txheej txheem nyob rau hauv lub kub kev lag luam.

Kub refining: los ntawm ore mus rau kub ntshiab

Kub txoj kev taug kev los ntawm nws daim ntawv nyoos raws li cov ore rau hauv cov hlau uas peb ntshaw pib nrog cov txheej txheem kub refining. Cov txheej txheem nyuaj no suav nrog ntau theem, txhua lub hom phiaj ntawm kev tshem tawm impurities thiab ua tiav qib siab ntawm purity. Thawj kauj ruam hauv kev ua kom zoo nkauj kub yog txhawm rau rho cov ore kub los ntawm lub ntiaj teb, tom qab ntawd zuaj nws thiab zom rau hauv cov hmoov zoo. Cov hmoov no ces dhau los ntawm cov txheej txheem tshuaj thiab lub cev uas cais cov kub los ntawm lwm cov zaub mov thiab impurities.

Ib txoj hauv kev zoo tshaj plaws ntawm kev ua kom kub yog siv cyanide leaching, qhov twg cov tshuaj cyanide yog siv rau cov kub ore kom yaj cov kub. Cov kev daws teeb meem yog tom qab ntawd ua tiav kom rov qab tau cov kub, uas yog ntxiv purified los ntawm cov txheej txheem xws li smelting thiab electrolysis. Cov txheej txheem no suav nrog kev siv cov kub kub thiab tshuaj lom neeg cov tshuaj tiv thaiv kom tshem tawm cov impurities seem, uas ua rau kub ntshiab uas ua tau raws li kev lag luam purity qauv.

Qhov tseem ceeb ntawm Purity hauv Kub Refining

Purity yog qhov tseem ceeb hauv cov txheej txheem kub refining vim nws ncaj qha cuam tshuam rau tus nqi thiab qhov zoo ntawm cov khoom kawg. Lub purity ntawm kub yog ntsuas nyob rau hauv carats, nrog 24-karat kub yog lub purest daim ntawv thiab muaj 99.9% kub. Qhov qis dua tus nqi karat, qis dua cov ntsiab lus kub. Piv txwv li, 18 karat kub muaj 75% kub thiab 25% lwm yam hlau. Kev ua tiav siab purity yog qhov tseem ceeb rau kev ua kom tau raws li cov kev cai nruj ntawm kev lag luam uas vam khom kub, xws li kev tsim cov hniav nyiaj hniav kub thiab khoom siv hluav taws xob.

Ntxiv nrog rau kev ua kom tau raws li cov qauv kev coj dawb huv, kev ua kom zoo nkauj kub kuj tseem ua lub luag haujlwm tseem ceeb hauv kev ua kom muaj kev coj ncaj ncees thiab muaj kev vam meej hauv kev lag luam. Lub luag haujlwm ntawm kev ua haujlwm kub ua kom zoo nrog rau kev siv cov txheej txheem ua phooj ywg ib puag ncig thiab kev ua haujlwm ntawm kev ua haujlwm ncaj ncees uas hais txog cov teeb meem cuam tshuam txog ib puag ncig thiab kev cuam tshuam ntawm kev ua haujlwm kub mining thiab refining.

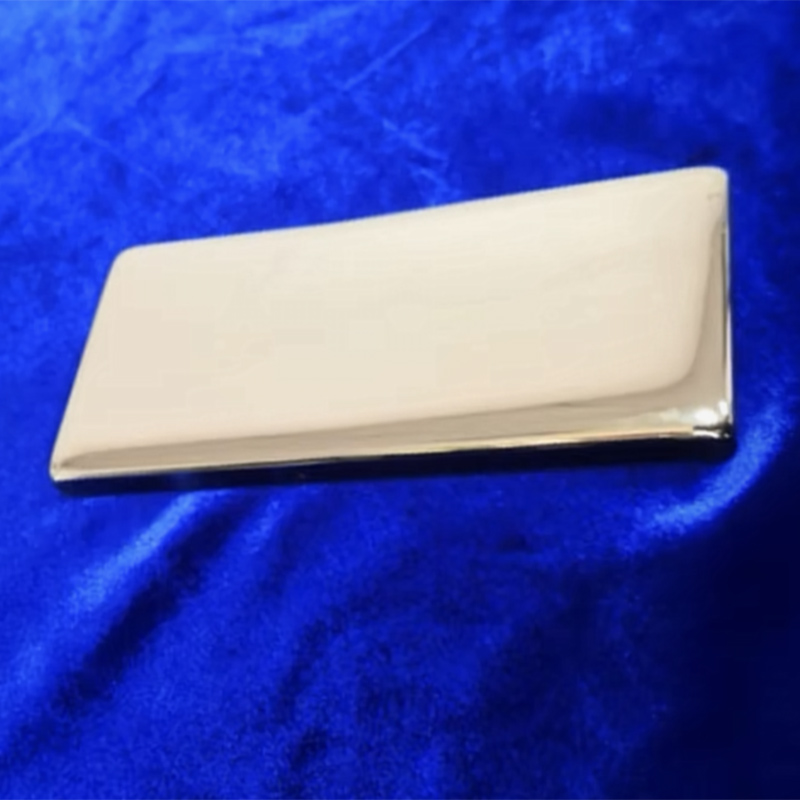

Kub Ingot Casting: Hloov cov kub refined rau hauv kub tuav

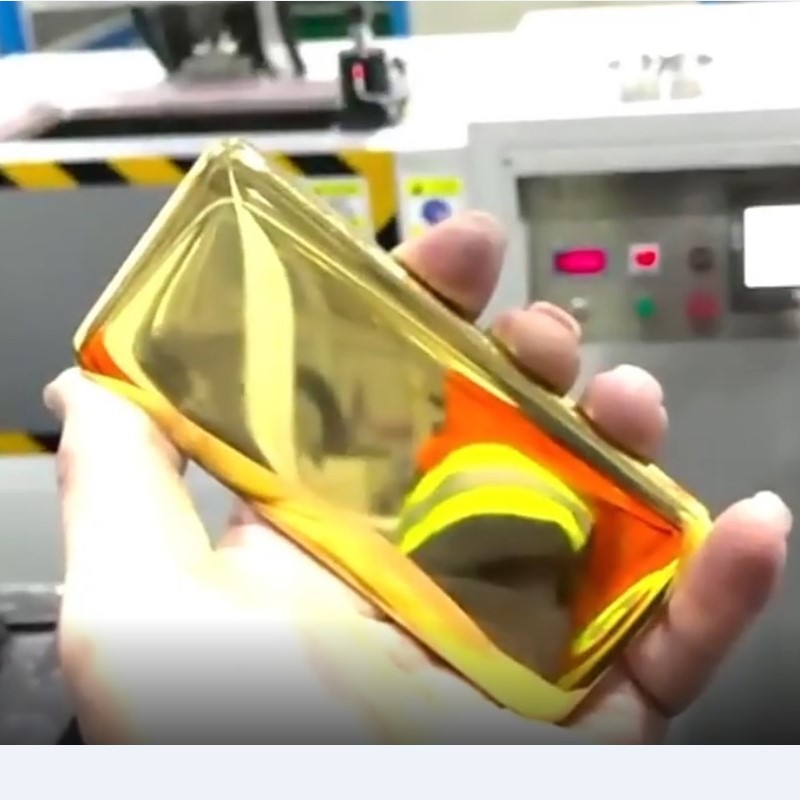

Thaum cov kub tau ua kom zoo rau qhov xav tau purity, nws tuaj yeem hloov mus rau hauv lub cim kub kub hu ua kub ingots. Cov txheej txheem ntawm kub ingot casting yuav tsum tau nchuav cov kub kub rau hauv pwm los ua cov khoom kub, ib qho yooj yim thiab qauv qauv ntawm kev lag luam thiab khaws cia. Cov txheej txheem no yuav tsum tau precision thiab kev txawj ntse los xyuas kom meej tias lub resulting ingot ua tau raws li qhov yuav tsum tau specifications ntawm qhov hnyav, qhov loj thiab purity.

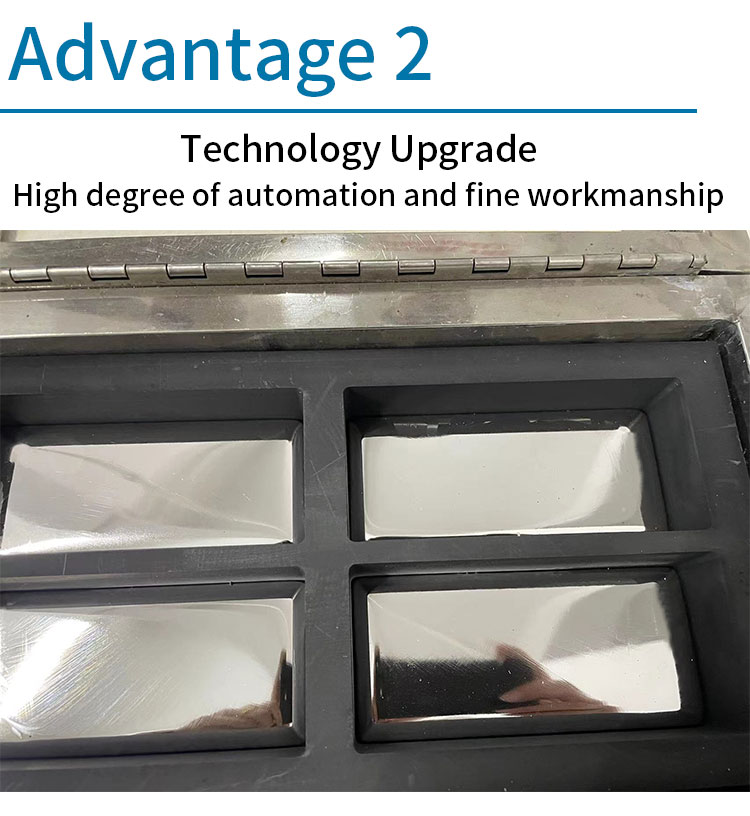

Thawj kauj ruam hauv kub ingot casting yog los npaj cov pwm, uas feem ntau yog ua los ntawm cov khoom siv ruaj khov xws li graphite lossis hlau. Pwm yog engineered los tsim kub ingots ntawm tej qhov hnyav thiab qhov ntau thiab tsawg, nrog rau cov cim qhia qhov purity thiab keeb kwm ntawm cov kub. Thaum cov pwm tau npaj lawm, cov kub ua kom zoo yog melted ntawm qhov kub thiab txias hauv crucible, feem ntau yog siv lub qhov cub induction lossis lwm yam khoom siv tshwj xeeb.

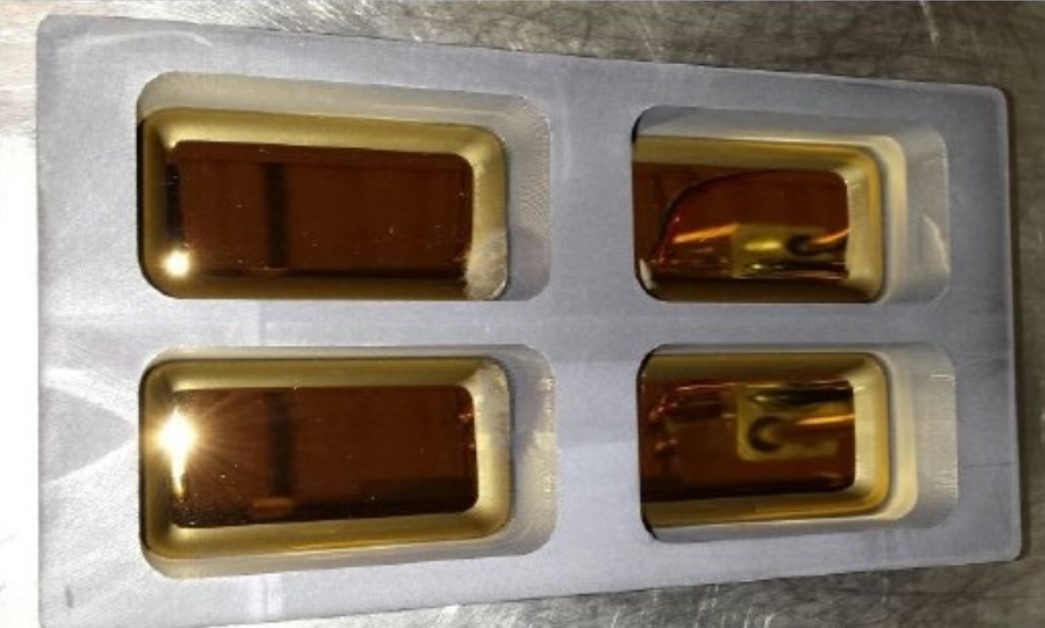

Cov kub molten yog ua tib zoo nchuav rau hauv cov pwm, ib txoj kev uas yuav tsum tau muaj kev txawj ntse thiab kev saib xyuas kom meej kom tsis txhob muaj qhov tsis zoo lossis qhov tsis sib xws hauv qhov kawg kub ingot. Tom qab cov kub solidifies, lub pwm yog qhib los qhia cov tshiab minted kub ingot, uas yog ces soj ntsuam thiab cim nrog ib tug cim cim los ua pov thawj nws purity thiab authenticity. Cov cim no feem ntau suav nrog qhov hnyav, purity thiab lub tuam txhab refining lub logo, muab cov ntaub ntawv tseem ceeb rau cov neeg yuav khoom thiab cov tub lag luam hauv khw kub.

Qhov tseem ceeb ntawm kub ingot casting hauv kev lag luam

Kub ingot casting yog ib qho tseem ceeb ntawm kev sib txuas ntawm cov txheej txheem kub refining thiab kev ua lag luam kub, muab cov qauv tsim thiab txheeb xyuas tau rau kev lag luam kub thiab khaws cia. Cov khoom kub no tau siv dav rau kev nqis peev nrog rau kev tsim cov hniav nyiaj hniav kub thiab lwm yam khoom kub. Cov txheej txheem ingot casting txheej txheem ua kom ntseeg tau tias cov kub ua tau raws li qhov xav tau purity thiab cov qauv zoo, txhawb kev ntseeg siab rau cov neeg yuav khoom thiab cov tub ua lag luam uas tso siab rau kev ncaj ncees ntawm cov kub uas lawv yuav.

Tsis tas li ntawd, kub bullion plays lub luag haujlwm tseem ceeb hauv kev lag luam kub thoob ntiaj teb raws li cov txiaj ntsig thoob ntiaj teb thiab cov khw muag khoom muaj nqis. Kub bullion tus qauv hnyav thiab purity ua rau nws zoo tagnrho rau kev lag luam thoob ntiaj teb thiab kev nqis peev, ua kom yooj yim rau kev lag luam thiab dhau los ua cov cuab yeej cuab tam txhim khu kev qha nyob rau lub sijhawm tsis muaj kev lag luam. Cov txheej txheem ingot casting yog li ntawd pab ua kom lub cev muaj zog thiab ruaj khov ntawm kev lag luam kub, tso cai rau seamless pauv ntawm kub thoob plaws ntiaj teb.

Lub neej yav tom ntej ntawm kub refining thiab ingot casting

Raws li kev thov rau kub tseem nce ntxiv, tau tsav los ntawm cov yam ntxwv xws li kev ruaj ntseg nyiaj txiag, kev tsim kho thev naus laus zis thiab kev coj noj coj ua tseem ceeb, kev lag luam kub refining yuav ua lub luag haujlwm tseem ceeb hauv kev ua kom tau raws li qhov kev thov no. Kev nce qib hauv kev siv thev naus laus zis thev naus laus zis thiab kev coj ua kom ruaj khov tau xav tias yuav txhim kho kev ua tau zoo thiab ib puag ncig cuam tshuam ntawm kev ua haujlwm kub refining, ua kom kev lag luam ua tau raws li cov qauv siab tshaj plaws ntawm kev coj ncaj ncees thiab lub luag haujlwm.

Ib yam li ntawd, cov txheej txheem kub ingot casting zoo li yuav txuas ntxiv rau kev tsim kho tshiab thiab txhim kho, nrog rau kev tsom mus rau qhov tseeb, automation, thiab kev hloov kho kom tau raws li qhov kev xav tau ntawm kev ua lag luam. Kev siv cov txheej txheem casting thiab cov khoom siv tau zoo tuaj yeem txhim kho qhov zoo thiab sib xws ntawm cov khoom siv kub, thaum cov thev naus laus zis digital thiab blockchain cov kev daws teeb meem tuaj yeem hloov pauv cov ntawv pov thawj thiab kev taug qab ntawm kub ingots, muab kev pom zoo dua rau cov neeg yuav khoom thiab cov tub ua lag luam. thiab kev ruaj ntseg.

Hauv kev xaus, cov txheej txheem kub refining thiab ingot casting yog ib feem tseem ceeb ntawm kev lag luam kub thiab txiav txim siab qhov zoo, tus nqi thiab kev ua lag luam ntawm cov hlau tseem ceeb no. Los ntawm kev tshem tawm cov impurities thaum lub sij hawm kub refining mus rau precision casting ntawm kub ingots, cov txheej txheem no qhia txog craftsmanship thiab kev txawj ntse ntawm kev lag luam kub. Raws li kev lag luam txuas ntxiv hloov zuj zus thiab hloov mus rau cov kev xav tau thiab cov qauv, kev kos duab thiab kev tshawb fawb ntawm kev ua kom zoo dua qub thiab ua cov kub tseem tseem ceeb heev kom ntseeg tau tias qhov kub tsis txaus siab thiab muaj txiaj ntsig hauv lub ntiaj teb niaj hnub no.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

.png)