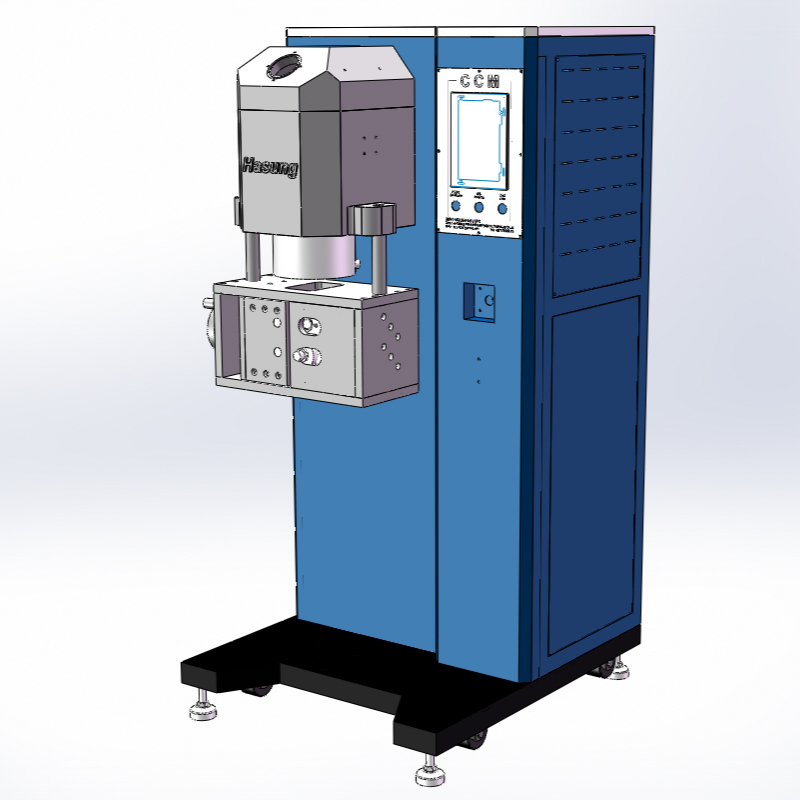

2019 Tuam Tshoj Tshiab Tsim Dt-Jd4 1600º C Electromagnetic Induction Cua sov plaub-Daim Nqus Ingot Casting Tshuab

Peb coj "cov neeg siv khoom zoo, zoo-oriented, integrative, innovative" raws li lub hom phiaj. "Qhov tseeb thiab kev ncaj ncees" yog peb cov thawj coj zoo tshaj plaws rau xyoo 2019 Tuam Tshoj Tshiab Tsim Dt-Jd4 1600º C Electromagnetic Induction Cua sov plaub lub Nqus Ingot Casting Tshuab, Peb zoo siab tos txais cov neeg siv khoom tshiab thiab dhau los ntawm txhua qhov chaw ntawm lub neej kom tau txais kev sib cuag nrog peb rau yav tom ntej kev lag luam me kev sib cuam tshuam thiab kev sib raug zoo!

Peb coj "cov neeg siv khoom zoo, zoo-oriented, integrative, innovative" raws li lub hom phiaj. "Qhov tseeb thiab kev ncaj ncees" yog peb cov thawj coj zoo rauTuam Tshoj Kub Bullion Ua Tshuab thiab Moulding Tshuab, Raws li lub ntiaj teb kev lag luam kev koom ua ke coj cov kev cov nyom thiab cov hauv kev rau kev lag luam xxx, peb lub tuam txhab, los ntawm kev ua haujlwm ntawm peb pab pawg, zoo ua ntej, kev tsim kho tshiab thiab kev sib nrig sib pab, muaj kev ntseeg siab txaus los muab peb cov neeg siv khoom zoo nrog cov khoom tsim nyog, cov nqi sib tw thiab kev pabcuam zoo, thiab tsim kom muaj lub neej yav tom ntej zoo dua nyob rau hauv lub siab ntawm siab dua, nrawm dua, muaj zog nrog peb cov phooj ywg ua ke los ntawm kev coj peb txoj kev qhuab qhia.

Nta

Lub Taiwan / Siemens PLC tswj qhov system ntawm no kub bullion casting tshuab coj tus nqi ntawm tag nrho koj cov txheej txheem casting. Koj tsuas yog xav tau ob peb feeb los teeb tsa lub sijhawm nkaus xwb, tom qab ntawd nias pib casting rau tag nrho cov haujlwm. Cov roj inert thiab lub tshuab nqus tsev no tau txais kev nkag siab thiab ua haujlwm zoo.

Nrog Hasung kub bar casting tshuab, koj yuav tsis tas yuav txhawj txog qhov zoo ntawm koj cov khoom siv vim tias lub tshuab twb tau pom zoo rau pawg mining kub loj tshaj plaws hauv Suav teb thiab peb tau dhau los ua nws cov khoom siv hlau tshwj xeeb.

Nrog lub tshuab nqus tsev kub bullion casting tshuab, koj tau lees paub ntawm kev ua haujlwm siab casting hauv koj lub zog noj. 20kW lub zog muab rau koj 6-8 feeb tag nrho casting rau txhua pawg. Lub tshuab muaj zog induction generator tuaj yeem ua kom sov koj cov hlau zoo nkauj rau txhua qhov kev xav tau melting kub. Siv lub ntiaj teb nto moo hom xws li Mitsubishi, Panasonic, SMC, Schneider Cheebtsam.

Kev nyab xeeb raug suav hais tias yog ib qho tseem ceeb thaum lub sij hawm tsim ntawm Hasung kub bar casting khoom. Lub tshuab nqus tsev yog qhov tseem ceeb thib ob rau cov cuab yeej xws li nws lav qhov zoo ntawm cov nyiaj kub kub.

Lub tshuab kuj tuaj yeem ntes tau yooj yim thaum muaj qhov system overvoltage lossis tsis txaus lossis dej tsis txaus, cov no yog cov kev nyab xeeb yooj yim xav tau rau peb cov tshuab.

Hasung lub tshuab nqus tsev kub bar casting system (HS-GV) thaum piv nrog rau lwm cov neeg sib tw hauv Suav teb. Lub tshuab tau nruab nrog ntau thiab ntau lub ntiaj teb cov npe nrov tshaj plaws thiab cov khoom siv hluav taws xob zoo tshaj plaws hauv kev lag luam engineering.

Technical Parameters

| Qauv No. | HS-GV 1 | HS-GV 2 |

| Puv Tsis Siv Neeg Qhib Npog Kub Bullion Nqus Casting Tshuab | ||

| Fais fab mov | 380V, 50/60Hz | |

| Lub zog nkag | 20 KW | 20 KW |

| Max Temp | 1600 ° C | |

| Lub Sijhawm Casting | 6-8 feeb. | 8-10 feeb. |

| Inert Gas | Argon / Nitrogen | |

| Inert gas filling | Tsis siv neeg | |

| Muaj peev xwm | 1pcs 1kg lossis 2pcs 0.5kg lossis ntau dua. | 2pcs 1kg lossis 4pcs 0.5kg lossis ntau dua. |

| Daim ntawv thov | Kub, Nyiaj (Platinum, Palladium customized) | |

| Lub tshuab nqus tsev | Lub tshuab nqus tsev zoo, nqus tsev kawm ntawv -98KPA, suav nrog | |

| Txoj kev ua haujlwm | Ib qho tseem ceeb ua haujlwm kom tiav tag nrho cov txheej txheem, POKA YOKE foolproof system | |

| Tswj qhov system | Taiwan / Siemens PLC + Tib neeg-tshuab interface ntse tswj qhov system (yeem) | |

| Hom cua txias | Dej chiller (muag nyias) los yog dej ntws | |

| Qhov ntev | 830x850x1010mm | 800x850x1000mm |

| Qhov hnyav | 180 KG | 180 KG |

Khoom Qhia

Puas yog kub kub 100% ntshiab kub?

Kub tau ua lub cim ntawm kev nplua nuj thiab kev vam meej rau ntau pua xyoo, thiab nws cov nqi tau nyob tas li thoob plaws hauv keeb kwm. Kub tuav yog ib qho ntawm cov qauv nrov tshaj plaws ntawm kev nqis peev hauv cov khoom lag luam hlau muaj txiaj ntsig, thiab lawv cov purity yog qhov tseem ceeb hauv kev txiav txim siab lawv tus nqi. Ntau tus neeg ua lag luam thiab cov neeg sau khoom feem ntau xav paub yog tias cov kub kub yog 100% ntshiab kub, thiab cov lus teb rau lo lus nug no yog nyob rau hauv cov txheej txheem ntawm cov khoom kub no.

Nyob rau hauv lub ntiaj teb no ntawm kub bar ntau lawm, qhov zoo ntawm cov machinery siv plays lub luag hauj lwm tseem ceeb nyob rau hauv kom ntseeg tau lub purity thiab kev ncaj ncees ntawm cov khoom kawg. Hasung yog ib lub tuam txhab ua lag luam ntawm cov khoom siv kub zoo tshaj plaws thiab ib txwm ua nyob rau hauv pem hauv ntej ntawm innovation thiab precision hauv kev lag luam. Lawv cov khoom siv hauv lub xeev yog tsim los tsim cov khoom kub ntawm qhov siab tshaj plaws purity, ua tau raws li cov qauv nruj raws li kev lag luam thoob ntiaj teb.

Txhawm rau kom nkag siab qhov purity ntawm cov khoom kub, nws yog ib qho tsim nyog yuav tsum tau nkag siab txog cov txheej txheem tsim khoom ntawm cov khoom muaj nqis. Kub tuav yog feem ntau yog ua los ntawm refined kub, uas yog melted thiab poured rau hauv pwm los tsim cov yam xav tau thiab loj. Lub purity ntawm cov kub siv nyob rau hauv cov txheej txheem no yog ntsuas nyob rau hauv carats, nrog 24-karat kub yog lub purest daim ntawv thiab muaj 99.9% kub. Txawm li cas los xij, nws tsim nyog sau cia tias txawm tias 24-karat kub tuav yuav tsis yog 100% ntshiab vim tias muaj cov kab mob thiab cov impurities.

Qhov no yog qhov uas lub luag hauj lwm ntawm Hasung lub high-zoo kub bar ua tshuab ua qhov tseem ceeb. Hasung's advanced technology thiab precision engineering xyuas kom meej tias cov kub siv nyob rau hauv cov txheej txheem raug refined mus rau lub siab tshaj plaws purity theem, minimizing impurities thiab ua tiav purity theem uas tau raws li los yog ntau tshaj kev lag luam qauv. Los ntawm kev siv cov tshuab txiav-ntug, Hasung muaj peev xwm tsim cov khoom kub ntawm cov purity siab heev, instilling kev ntseeg siab ntawm cov tub ua lag luam thiab cov neeg sau.

Cov txheej txheem ntawm refining kub kom ua tiav qhov yuav tsum tau purity yuav tsum muaj ntau theem, txhua yam yuav tsum tau precision thiab kev txawj ntse. Hasung lub kub bar ua tshuab tau nruab nrog cov kev ua kom zoo tshaj plaws nrog rau kev tswj xyuas qhov kub thiab txias, pom cov tshuab thiab cov txheej txheem automated uas txo qis tib neeg kev ua yuam kev. Cov txheej txheem thev naus laus zis no ua kom ntseeg tau tias cov kub tau ua kom huv huv, ua rau cov kub purity siab.

Ntxiv nrog rau purity, qhov zoo ntawm qhov chaw thiab tag nrho cov tsos ntawm lub kub bar yog qhov tseem ceeb hauv kev txiav txim siab nws tus nqi. Hasung lub kub bar ua tshuab yog tsim los tsim cov kub tuav nrog ib tug zoo meej nto, tsis muaj blemishes thiab imperfections. Lub precision molding thiab casting txheej txheem siv los ntawm Hasung xyuas kom meej tias cov khoom kawg ua tau raws li cov qauv zoo nkauj tshaj plaws, yog li txhim kho nws cov kev xav tau ntawm kev lag luam.

Tsis tas li ntawd, kev ua tau zoo thiab kev tsim khoom ntawm Hasung kub bar ua tshuab pab txhim kho tag nrho qhov zoo ntawm cov khoom kawg. Los ntawm kev txhim kho cov txheej txheem tsim khoom thiab txo cov khoom pov tseg, Hasung cov cav tov muaj peev xwm tsim tau cov khoom kub zoo yam tsis muaj kev cuam tshuam rau qhov zoo. Qhov kev ua tau zoo no txhais tau tias ntau dua cov khoom siv kub zoo kom tau raws li qhov xav tau ntawm kev lag luam ntse.

Kev ntseeg tau thiab sib xws ntawm Hasung kub bar ua tshuab yog ntxiv rau hauv lawv txoj kev ua raws li cov qauv zoo thoob ntiaj teb thiab cov ntawv pov thawj. Hasung tau cog lus tias yuav ua raws li qib siab tshaj plaws ntawm kev tswj hwm zoo thiab ua raws li cov cai hauv kev lag luam kom ntseeg tau tias nws cov tshuab xa cov kev ua tau zoo thiab kev ntseeg siab. Qhov kev mob siab rau qhov kev lees paub zoo no ua rau muaj kev ntseeg siab rau cov neeg siv khoom, paub tias lawv tau nqis peev hauv cov tshuab ua tau raws li cov qauv nruj tshaj plaws.

Nyob rau hauv cov ntsiab lus, purity ntawm kub tuav yog ib qho tseem ceeb rau cov tub ua lag luam thiab cov neeg sau khoom, thiab qhov zoo ntawm cov tshuab siv los tsim cov tuav ua lub luag haujlwm tseem ceeb hauv kev ua tiav qhov purity no. Hasung cov khoom kub zoo ua tshuab yog tsim los ua kom zoo dua qub thiab pwm kub, ua cov kub kub ntawm qhov tshwj xeeb purity thiab zoo. Nrog rau kev tsom mus rau kev tsim kho thev naus laus zis, kev ua tau zoo thiab kev ntseeg siab, Hasung tau dhau los ua cov chaw tsim khoom lag luam hauv kev lag luam kub bar, muab cov kev daws teeb meem zoo rau cov neeg nrhiav cov qauv siab tshaj plaws ntawm kev coj dawb huv thiab kev ua haujlwm hauv lawv cov peev nyiaj kub.

Peb coj "cov neeg siv khoom zoo, zoo-oriented, integrative, innovative" raws li lub hom phiaj. "Qhov tseeb thiab kev ncaj ncees" yog peb cov thawj coj zoo tshaj plaws rau 2019 Tuam Tshoj Tshiab Tsim HS-GV4 1600º C Electromagnetic Induction Cua Sov Plaub Ntu Nqus Ingot Casting Tshuab, Peb zoo siab tos txais cov neeg siv khoom tshiab thiab dhau los ntawm txhua qhov chaw ntawm lub neej kom tau txais kev sib cuag nrog peb rau yav tom ntej kev lag luam me kev sib cuam tshuam thiab kev sib raug zoo!

2019 Tuam Tshoj Tshiab Tsim Tuam Tshoj Kub Bar Ua Tshuab thiab Moulding Tshuab, Raws li lub ntiaj teb kev lag luam kev sib koom ua ke coj cov kev cov nyom thiab cov hauv kev rau kev lag luam hlau muaj txiaj ntsig, peb lub tuam txhab, los ntawm kev nqa peb pab pawg ua haujlwm, ua ntej, kev tsim kho tshiab thiab kev sib koom ua ke, muaj kev ntseeg siab txaus los muab peb cov neeg tau txais txiaj ntsig zoo nrog cov khoom tsim nyog, cov nqi sib tw thiab cov kev pabcuam zoo, thiab tsim kom muaj lub neej yav tom ntej nyob rau hauv lub siab ntawm siab dua, nrawm dua, muaj zog nrog peb cov phooj ywg ua ke los ntawm kev coj peb cov kev qhuab qhia.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur